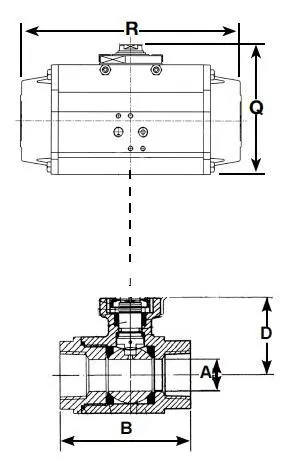

Features:

Size 1/4" to 2" BSP

Body 316 Stainless Steel

Seat Delrin

Pressure 200 BAR

Temperature Ambient

Actuation Double Acting Pneumatic

Series BLSHP high performance 316 stainless steel ball valves are specifically designed for high pressure applications. Delrin seats enable pressures up to 204 BAR or 3000 psi at 38°C. Comes with double acting anodised aluminium actuator with visual indicator. Typical applications include water blasting, chemical injection, boiler feedwater and agricultural spraying. Threads conform to ISO 7.1 Sealing Threads.

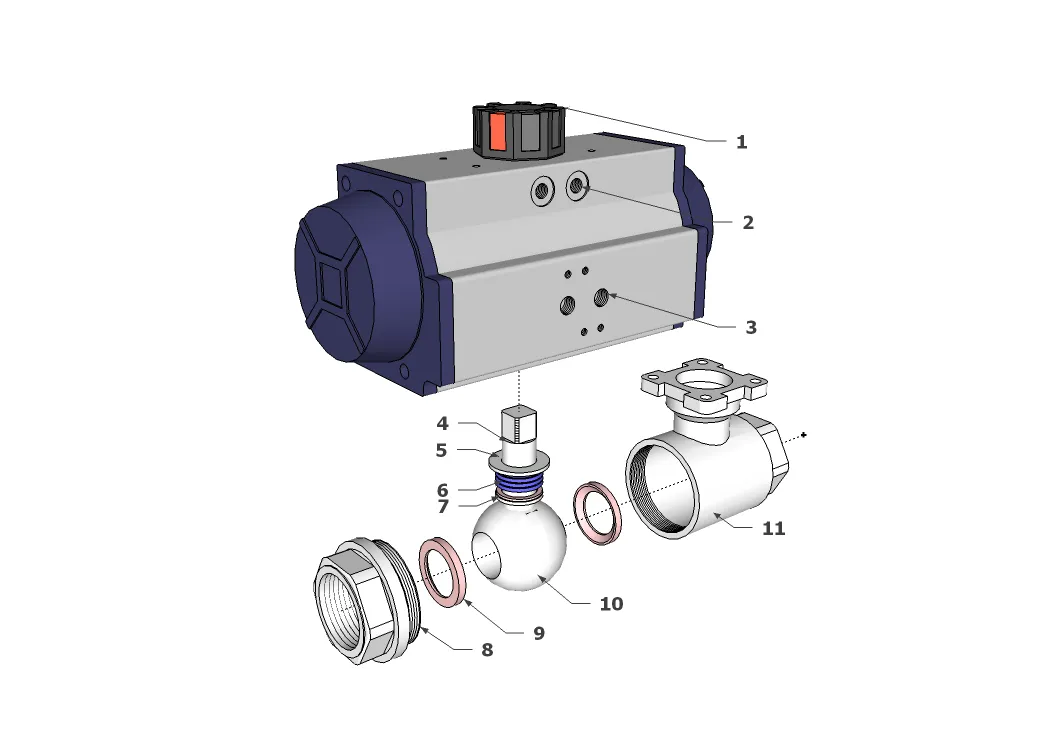

| Number | Part | Material |

|---|---|---|

| 1 | Visual Indicator | UV Stabilized Thermoplastic |

| 2 | Stops | Stainless Steel |

| 3 | Inlet Ports/Namur Interface | Anodised Aluminium |

| 4 | Drive | 316 Stainless Steel |

| 5 | Chevron Seals | Delrin |

| 6 | Backing O-Ring | Viton |

| 7 | Thrust Washer | Delrin |

| 8 | End Piece | 316 Stainless Steel |

| 9 | Seat | Delrin |

| 10 | Ball | 316 Stainless Steel |

| 11 | Body | 316 Stainless Steel |

Size 1/4" to 2" BSP

Body 316 Stainless Steel

Seat Delrin

Pressure 200 BAR

Temperature Ambient

Actuation Double Acting Pneumatic

What is a High Pressure Double Acting Pneumatic Stainless Steel Ball Valve?

A high pressure two way double acting stainless steel ball valve is constructed of two seperate body pieces made of cast 316 stainless steel pieces which are threaded together and hydraulically locked. The wall thickness is usually much larger than a lower pressure ball valve as it can accomodate a much higher pressure range (ours will do up to 200 Bar). The seats are Delrin which is great for high pressures but has a narrower range of compatible media when compared with PTFE which is typically used at lower pressures. It has a direct mounted anodised aluminium rack and pinion actuator fixed to the valve which conducts its 90 degree turn (open.close). The actuator has a namur interface and position indicator.

How does a 2 way High Pressure Double Acting Stainless Steel Ball Valve work?

These high pressure double acting ball valves work the same as any normal two way ball valve whereby the ball is rotated 90 degrees within the body of the valve which will either open or close the valve. The ball itself (solid ball design for higher pressures) has a hole either end which the media will flow through when it is open. When the valve is closed these holes are blocked off to the flow effectively isolating the media either side of the valve. The seal is provided by a Delrin seat (good for high pressure applications) at either end of the ball. The ball is turned by a double acting rack & pinion actuator which is connected to a shaft which in turn is mated to the ball by a female slot. When the actuator is operated by a 5/2 valve (all double acting actuators need a 5/2 valve to operate, the most common we see is a 5/2 direct interfacing namur solenoid valve) the shaft will be rotated effectively turning the ball inside the cavity and switching it to its other state (either open or close). Extras such as limit switch boxes and positioners can also be mounted directly to the actuator.

How long will High Pressure Double Acting Stainless Steel Ball Valve last?

Like any valve this depends upon the usage case of your ball valve, its environment, media and how many times it is cycled. For instance if it is on a clean media, in a clean environment and not cycled regularly the life will be decades or more. If it is on a corrosive media and in a dry application with a high cycle rate the life will be much shorter. We conduct regular lab testing and 10,000 cycles is a reasonable life cycle for the ball valve depending upon the application. The actuators life will depend upon how clean and dry the supply air is (the air that makes the actuator operate) however we regularly test these to over 800,000 cycles. Install a basic air filter if you are not sure about the quality of your air, we have pneumatic actuators that have been in operation for decades. The most common failure we see is due to dirty wet air being sent to the actuator.

How do I install a High Pressure Double Acting Stainless Steel Ball Valve?

These have female parallel BSP threaded ends so it is best to put a male tapered BSP fitting into the valve ends. Thread tape or a sealant should be used to help the seal and also if dissimilar metals are used it will reduce dissimilar metal corrosion. As this is potentially working at higher pressures a firm seal needs to be achieved. The double acting actuator can accommodate a namur solenoid valve which is a very popular configuration (the 5/2 control valve bolts directly onto the actuator with an o-ring face seal on the back of the valve) or just a standalone 5/2 valve. If you are using a stand alone 5/2 valve the air lines will need to be run from here into the ports on the actuator (remember the longer the run the slower the operation unless you use quick exhaust valves near the actuator).

What are typical uses of a High Pressure Double Acting Stainless Steel Ball Valve?

These are generally used in high pressure applications where no fail safe position is needed (being double acting if you lose air it will stay in whatever position the valve is in). If fail safe is needed a spring return unit would be better suited. Common applications we see are water blasting/spraying and chemical injection.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

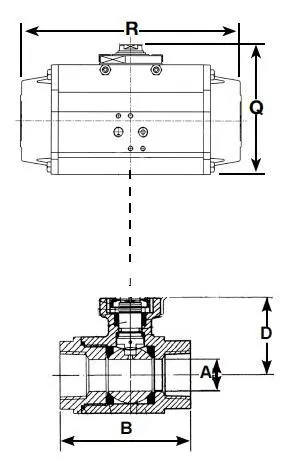

Size 1/4" to 2" BSP

Body 316 Stainless Steel

Seat Delrin

Pressure 200 BAR

Temperature Ambient

Actuation Double Acting Pneumatic

Series BLSHP high performance 316 stainless steel ball valves are specifically designed for high pressure applications. Delrin seats enable pressures up to 204 BAR or 3000 psi at 38°C. Comes with double acting anodised aluminium actuator with visual indicator. Typical applications include water blasting, chemical injection, boiler feedwater and agricultural spraying. Threads conform to ISO 7.1 Sealing Threads.

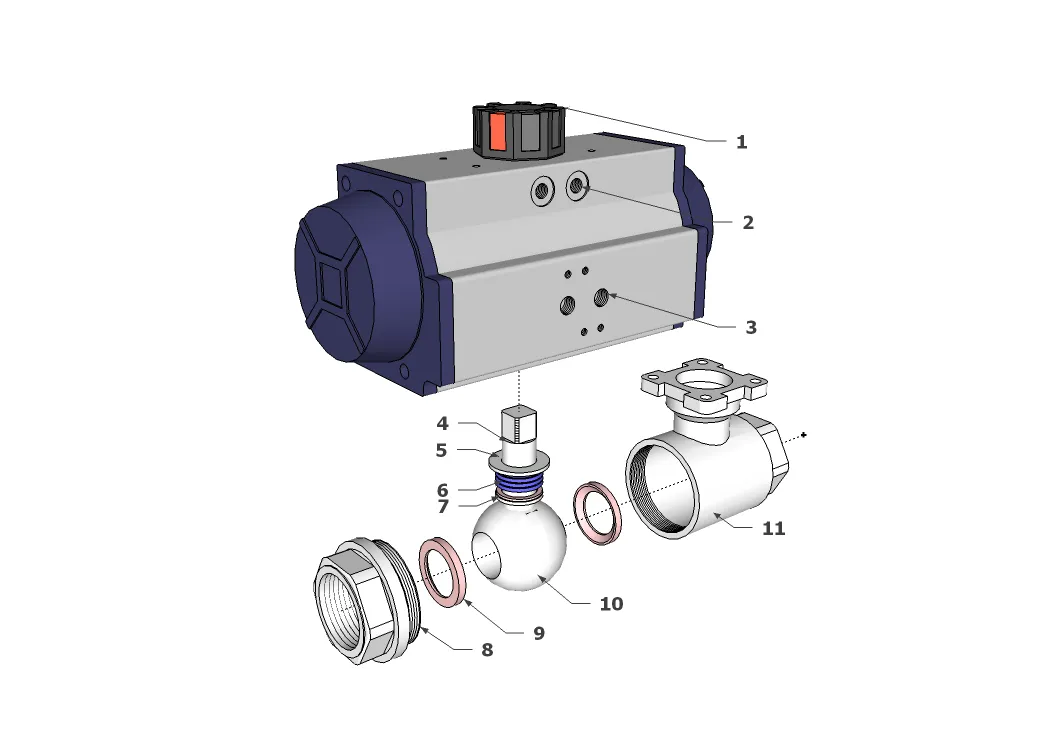

| Number | Part | Material |

|---|---|---|

| 1 | Visual Indicator | UV Stabilized Thermoplastic |

| 2 | Stops | Stainless Steel |

| 3 | Inlet Ports/Namur Interface | Anodised Aluminium |

| 4 | Drive | 316 Stainless Steel |

| 5 | Chevron Seals | Delrin |

| 6 | Backing O-Ring | Viton |

| 7 | Thrust Washer | Delrin |

| 8 | End Piece | 316 Stainless Steel |

| 9 | Seat | Delrin |

| 10 | Ball | 316 Stainless Steel |

| 11 | Body | 316 Stainless Steel |