Features:

Size 1/4" to 1" BSP

Body 316 Stailess Steel

Pressure Range 0 to 400 BAR

Factory Accredited CE, ISO 9001

316 Stainless Steel needle valve allows the user to precisely control unidirectional flow by screwing the needle down onto a seat. Rated to 408 BAR (6000 psi) with T bar handle. Great for use on compatable fluids and gases.

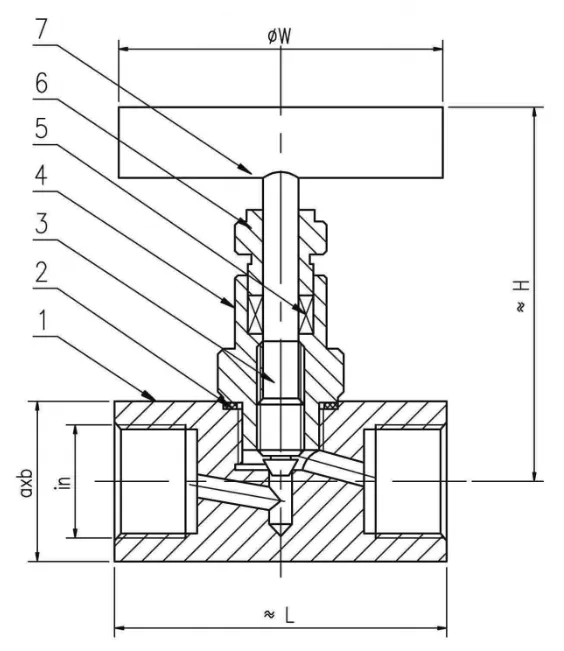

| Model | Size | L | a | b | W | H |

|---|---|---|---|---|---|---|

| NVS-01 | 1/8" | 56 | 28 | 28 | 60 | 80 |

| NVS-02 | ¼” | 56 | 28 | 28 | 60 | 80 |

| NVS-03 | 3/8” | 56 | 28 | 28 | 60 | 80 |

| NVS-04 | ½” | 58 | 28 | 28 | 60 | 81 |

| NVS-05 | ¾” | 62 | 35 | 35 | 60 | 85 |

| NVS-06 | 1” | 70 | 45 | 45 | 70 | 100 |

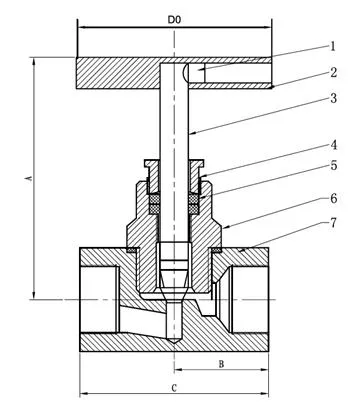

| Number | Name | Material |

|---|---|---|

| 1 | Set Screw | SS304 |

| 2 | Handle | SS304 |

| 3 | Stem | SS316 |

| 4 | Gland Nut | SS316 |

| 5 | Packing | TEFLON |

| 6 | Bonnet | ASTM A-351 GR. CF3M |

| 7 | Body | ASTM A-351 GR. CF3M |

Size 1/4" to 1" BSP

Body 316 Stailess Steel

Pressure Range 0 to 400 BAR

Factory Accredited CE, ISO 9001

What is a Needle Valve?

A needle valve is used for fine flow control of fluids and gas. They have low flow but accommodate very high differential pressures (up to 400 Bar pressure and 230 deg.C temperature) giving precision control with small rotational movement of the handle. By nature the orifice is usually much smaller that the inlet connection (for more general control including full flow a globe valve is used). Our needle valves are machined from a solid block of 316 Stainless Steel but you can find them in various other materials depending upon the application.

How does a Stainless Steel Needle Valve work?

A needle valve has a tapered spindle with a fine rotational thread giving precision control. Turning the handle makes the plunger move up or down into a tapered orifice. This allows precision flow control of the media. The valve stem has a safety block to stop it completely unscrewing. The valve port is usually threaded with a solid machined body in SS316 stainless steel.

How long will my Needle Valve last?

Like any valve this depends upon the maintenance of the assembly - in this case using a filtered media. Regular scheduled maintenance of the unit to clean the needle is standard procedure. They have few moving parts so if the media is not aggressive it will last a very long time.

How do I install a Needle Valve?

The needle valve can be installed in any position. Direction of flow is indicated on the side of the body and will need to be followed for proper flow regulation (the flow will enter under the seat. As these can operate at high pressure care needs to be taken to use the correct fitting joining the needle valve to the line.

What are typical uses of a Needle Valve?

This type of valve has many uses. Understanding the application is important. This is a presion device with a small orifice (ie a 1”Bsp valve has an 8mm dia orifice). It can accommodate up to 6000 psi differential pressure with a fine control. They control flow in only one direction. The media can go in the reverse direction but not with the same precision of control. Common uses include shut off valves for gas, high pressure air isolation for pressure gauges, control of flow for metering devices, control of water and bleed valves for double block & bleed assemblies.

How long will my Needle Valve take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 3 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse inspected so there are rarely any issues. Once your valve is in and operating it will most likely continue to do so for a very long time. They also have available full material and testing certificates.

Size 1/4" to 1" BSP

Body 316 Stailess Steel

Pressure Range 0 to 400 BAR

Factory Accredited CE, ISO 9001

316 Stainless Steel needle valve allows the user to precisely control unidirectional flow by screwing the needle down onto a seat. Rated to 408 BAR (6000 psi) with T bar handle. Great for use on compatable fluids and gases.

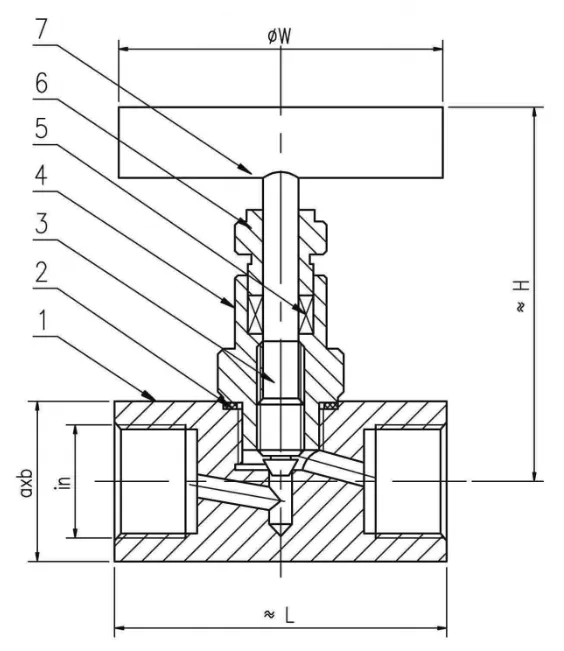

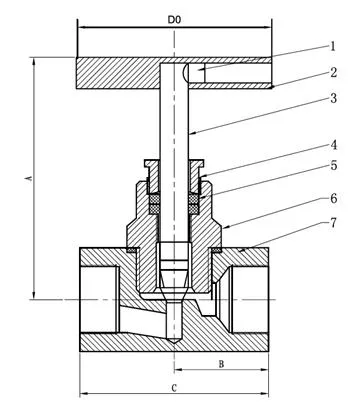

| Model | Size | L | a | b | W | H |

|---|---|---|---|---|---|---|

| NVS-01 | 1/8" | 56 | 28 | 28 | 60 | 80 |

| NVS-02 | ¼” | 56 | 28 | 28 | 60 | 80 |

| NVS-03 | 3/8” | 56 | 28 | 28 | 60 | 80 |

| NVS-04 | ½” | 58 | 28 | 28 | 60 | 81 |

| NVS-05 | ¾” | 62 | 35 | 35 | 60 | 85 |

| NVS-06 | 1” | 70 | 45 | 45 | 70 | 100 |

| Number | Name | Material |

|---|---|---|

| 1 | Set Screw | SS304 |

| 2 | Handle | SS304 |

| 3 | Stem | SS316 |

| 4 | Gland Nut | SS316 |

| 5 | Packing | TEFLON |

| 6 | Bonnet | ASTM A-351 GR. CF3M |

| 7 | Body | ASTM A-351 GR. CF3M |