Features:

Torque 35 to 3500 NM

Function Drive Open/Drive Close, 90 degree turn

Body Powder Coated Die Cast Aluminium

Voltage 12vDC, 24vDC, 24v AC, 110vAC, 240vAC

Rating IP67

The 0M series is a robust range of 1/4 turn (90 degrees) actuators suitable for on/off actuation of butterfly or ball valves. A powerful motor with inbuilt thermal protection drives a pre-lubricated heavy duty steel gear train running on bronze bushes. Encased in a powder coated die cast protective housing giving it an IP67 rating (dust tight and submersible for limited periods). Cable connection is made through 2 of M20x1.5 cable entries. All models have visual indicator, extra limit switches and a manual override. Duty cycle is dependant on ambient temperature, voltage and actuator model, and relates to the 135°C thermal motor protection.

The start and run currents are measured at the maximum torque of the actuator.

| Model | Torque (Nm) | Time (seconds) | (AMP) 12v DC | (AMP) 24v AC/DC | (AMP) 110v AC | (AMP) 240v AC | (AMP) 415v AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AC | DC | Run | Start | Duty | Run | Start | Duty | Run | Start | Duty | Run | Start | Duty | Run | Start | Duty | ||

| OM-1 | 35 | 13 | 15 | 1.9 | 2 | 75% | 1.1 | 1.1 | 75% | 0.6 | 0.6 | 30%* | 0.3 | 0.4 | 30%* | - | - | - |

| OM-A | 50 | 24 | 20 | 1.3 | 1.5 | 75% | 0.8 | 0.9 | 75% | 0.6 | 0.6 | 30%* | 0.3 | 0.4 | 30%* | - | - | - |

| OM-2 | 90 | 17 | 15 | 3.4 | 5.2 | 75% | 2.2 | 4.5 | 75% | 1 | 1.8 | 30%* | 0.5 | 0.8 | 30%* | 0.4 | 0.9 | 30% |

| OM-3 | 150 | 26 | 22 | 4.4 | 4.9 | 75% | 2.4 | 5 | 75% | 1.2 | 1.8 | 30%* | 1 | 1.2 | 30%* | 0.4 | 0.9 | 30% |

| OM-4 | 400 | 18 | 16 | 16.1 | 16.1 | 75% | 8.5 | 9.2 | 75% | 1.9 | 3.8 | 30%* | 1.1 | 2 | 30%* | 0.6 | 1.4 | 30% |

| OM-5 | 500 | 25 | 22 | 14.1 | 13.5 | 75% | 7.5 | 9 | 75% | 2 | 3.8 | 30%* | 1.1 | 2 | 30%* | 0.6 | 1.4 | 30% |

| OM-6 | 650 | 31 | 28 | 12.3 | 12.5 | 75% | 7 | 8.5 | 75% | 2.1 | 3.8 | 30%* | 1.1 | 2 | 30%* | 0.6 | 1.4 | 30% |

| OM-7 | 1000 | 55 | 46 | - | - | 75% | 6.8 | 7.8 | 75% | 3.1 | 8.5 | 30%* | 1.4 | 4.1 | 30%* | 0.5 | 1.3 | 30% |

| OM-8 | 1500 | 55 | 46 | 25 | 26 | 75% | 8.1 | 8 | 75% | 3.3 | 9 | 30%* | 1.6 | 4.4 | 30%* | 0.6 | 1.2 | 30% |

| OM-9 | 2000 | 70 | 58 | - | - | 50% | 8.8 | 11 | 50% | 3.3 | 5.8 | 30%* | 2.1 | 3.8 | 30%* | 0.7 | 2 | 30% |

| OM-10 | 2500 | 70 | 58 | 28 | 60 | 50% | 11.8 | 11 | 50% | 4 | 6.5 | 30%* | 2.3 | 4 | 30%* | 0.7 | 2 | 30% |

| OM-11 | 3000 | 70 | 58 | - | - | 50% | 15.1 | 11 | 50% | 4.5 | 6.5 | 30%* | 2.5 | 4.2 | 30%* | 0.7 | 2 | 30% |

| OM-12 | 3500 | 70 | 58 | - | - | 50% | 17.8 | 12 | 50% | 4 | 8 | 30%* | 2.4 | 4.4 | 30%* | 0.8 | 2.6 | 30% |

| OM-13 | 4500 | 50% | 50% | 4.2 | 8 | 30%* | 2.4 | 4.8 | 30%* | 0.8 | 2.6 | 30% | ||||||

The start and run currents are measured at the maximum torque of the actuator.

*50% & 75% Duty Cycle available as an option depending on Actuator model, contact Sales for more information. Please see the 0M Series Wiring Diagrams for further wiring detail.

Optional Extras:

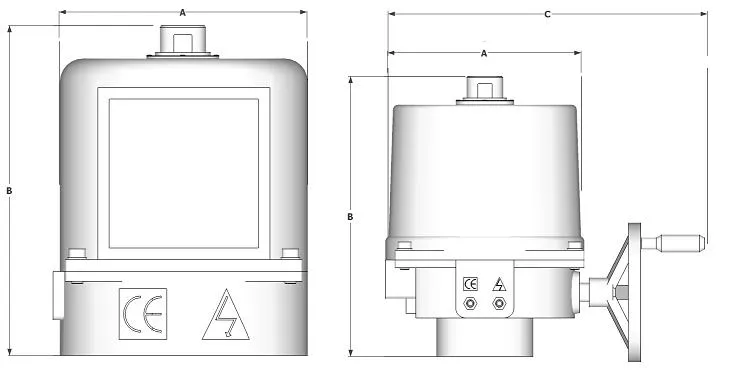

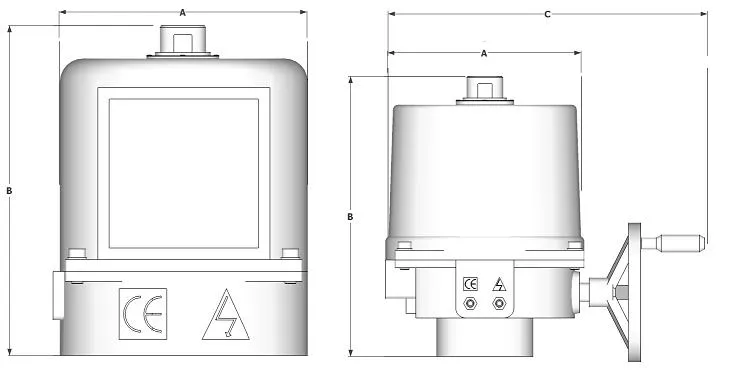

0M-A & 0M-1 0M-2 & Above

| Model | A (mm) | B (mm) | C (mm) | ISO 5211 Mounting | Female Drive | End Stops | Manual Override |

|---|---|---|---|---|---|---|---|

| OM-1 | 108 | 155 | - | FO3 / FO5 | 14mm Star | NO | Spanner Drive |

| OM-A | 130 | 200 | - | F05/FO7 | 17mm Star | NO | Allen Key Drive |

| OM-2 | 200 | 290 | 330 | FO7/F10 | 22mm Star | Yes | Hand wheel |

| OM-3 | 200 | 290 | 330 | FO7/F10 | 22mm Star | Yes | Hand wheel |

| OM-4 | 234 | 315 | 380 | F10/F12 | 36mm Star | Yes | Hand wheel |

| OM-5 | 234 | 315 | 380 | F10/F12 | 36mm Star | Yes | Hand wheel |

| OM-6 | 234 | 315 | 380 | F10/F12 | 36mm Star | Yes | Hand wheel |

| OM-7 | 234 | 420 | 520 | F14 | 36mm Star | Yes | Hand wheel |

| OM-8 | 234 | 420 | 520 | F14 | 36mm Star | Yes | Hand wheel |

| OM-9 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-10 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-11 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-12 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-13 | F16/F25 | O 75mm Keyway | Yes | Hand wheel |

Torque 35 to 3500 NM

Function Drive Open/Drive Close, 90 degree turn

Body Powder Coated Die Cast Aluminium

Voltage 12vDC, 24vDC, 24v AC, 110vAC, 240vAC

Rating IP67

What is an Electric Actuator?

A 90 degree turn electric actuator is an actuator that can turn 90 degrees using electricity. This is usually mounted to a 90 degree turn valve such as a ball or butterfly valve and allows the valve to fully open or fully close. When sizing an electric actuator to a valve it is common practice to size the torque with a 30% safety margin. Also the mounting pad, drive size and duty cycle of the unit will be important to note. They are available in most common voltages including 12vDC, 24v DC, 24v AC, 110v AC, 240v AC & 415v AC (depending upon model). They also come in full stainless steel and explosion proof variants.

How does an electric actuator work?

A 90 degree turn electric actuator works by powering the actuator open or closed through the use of an electric motor and gearing. The size of the motor and the number of gears vary depending upon the size of the actuator (there is a range of actuators with varying torques which are matched to the torque of the valve). The actuator is operated by an external relay and can take anywhere from 8 to 20 seconds for one cycle depending upon the size of the actuator. Once it completes its required 90 degrees a microswitch which is mounted on a cam is triggered and power to the motor is shut off. The actuator will then wait for the relay to be switched and it will do the same thing in the other direction.

How long will my electric actuator last?

Like any actuator this depends upon the usage case, its environment, media and how many times it is cycled. Our electric actuators are certified for 6,000 starts under full load which is part of the CE standard. Obviously, things like running above the rated duty cycle, torque overload, water entering the actuator and other factors will lead to premature failure. The actuator may last well past this point as well if it is looked after and in a clean environment.

How do I install an electric actuator?

These electric actuators come with a wiring diagram on the cover of the valve and the underside as well. They need to be wired in accordance with these wiring diagrams which vary between models and voltages. One common failure we see is an incorrectly rated cable entry which lets moisture into the actuator. The actuator is IP67 so it is best to ensure the cable entry gland is rated to at least this to preserve the performance of the actuator. We recommend installation of these items in an upright position. However they can be mounted from upright position to 90 degree if required. Please make sure correct cable gland is used and wiring connection is facing downwards if at 90 Degrees.

What are typical uses of an electric actuator?

These have a wide range of uses but we mostly see them ball and butterfly valves (anywhere where a 90 degree turn is required). This could be in steam, water or another media.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Torque 35 to 3500 NM

Function Drive Open/Drive Close, 90 degree turn

Body Powder Coated Die Cast Aluminium

Voltage 12vDC, 24vDC, 24v AC, 110vAC, 240vAC

Rating IP67

The 0M series is a robust range of 1/4 turn (90 degrees) actuators suitable for on/off actuation of butterfly or ball valves. A powerful motor with inbuilt thermal protection drives a pre-lubricated heavy duty steel gear train running on bronze bushes. Encased in a powder coated die cast protective housing giving it an IP67 rating (dust tight and submersible for limited periods). Cable connection is made through 2 of M20x1.5 cable entries. All models have visual indicator, extra limit switches and a manual override. Duty cycle is dependant on ambient temperature, voltage and actuator model, and relates to the 135°C thermal motor protection.

The start and run currents are measured at the maximum torque of the actuator.

| Model | Torque (Nm) | Time (seconds) | (AMP) 12v DC | (AMP) 24v AC/DC | (AMP) 110v AC | (AMP) 240v AC | (AMP) 415v AC | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AC | DC | Run | Start | Duty | Run | Start | Duty | Run | Start | Duty | Run | Start | Duty | Run | Start | Duty | ||

| OM-1 | 35 | 13 | 15 | 1.9 | 2 | 75% | 1.1 | 1.1 | 75% | 0.6 | 0.6 | 30%* | 0.3 | 0.4 | 30%* | - | - | - |

| OM-A | 50 | 24 | 20 | 1.3 | 1.5 | 75% | 0.8 | 0.9 | 75% | 0.6 | 0.6 | 30%* | 0.3 | 0.4 | 30%* | - | - | - |

| OM-2 | 90 | 17 | 15 | 3.4 | 5.2 | 75% | 2.2 | 4.5 | 75% | 1 | 1.8 | 30%* | 0.5 | 0.8 | 30%* | 0.4 | 0.9 | 30% |

| OM-3 | 150 | 26 | 22 | 4.4 | 4.9 | 75% | 2.4 | 5 | 75% | 1.2 | 1.8 | 30%* | 1 | 1.2 | 30%* | 0.4 | 0.9 | 30% |

| OM-4 | 400 | 18 | 16 | 16.1 | 16.1 | 75% | 8.5 | 9.2 | 75% | 1.9 | 3.8 | 30%* | 1.1 | 2 | 30%* | 0.6 | 1.4 | 30% |

| OM-5 | 500 | 25 | 22 | 14.1 | 13.5 | 75% | 7.5 | 9 | 75% | 2 | 3.8 | 30%* | 1.1 | 2 | 30%* | 0.6 | 1.4 | 30% |

| OM-6 | 650 | 31 | 28 | 12.3 | 12.5 | 75% | 7 | 8.5 | 75% | 2.1 | 3.8 | 30%* | 1.1 | 2 | 30%* | 0.6 | 1.4 | 30% |

| OM-7 | 1000 | 55 | 46 | - | - | 75% | 6.8 | 7.8 | 75% | 3.1 | 8.5 | 30%* | 1.4 | 4.1 | 30%* | 0.5 | 1.3 | 30% |

| OM-8 | 1500 | 55 | 46 | 25 | 26 | 75% | 8.1 | 8 | 75% | 3.3 | 9 | 30%* | 1.6 | 4.4 | 30%* | 0.6 | 1.2 | 30% |

| OM-9 | 2000 | 70 | 58 | - | - | 50% | 8.8 | 11 | 50% | 3.3 | 5.8 | 30%* | 2.1 | 3.8 | 30%* | 0.7 | 2 | 30% |

| OM-10 | 2500 | 70 | 58 | 28 | 60 | 50% | 11.8 | 11 | 50% | 4 | 6.5 | 30%* | 2.3 | 4 | 30%* | 0.7 | 2 | 30% |

| OM-11 | 3000 | 70 | 58 | - | - | 50% | 15.1 | 11 | 50% | 4.5 | 6.5 | 30%* | 2.5 | 4.2 | 30%* | 0.7 | 2 | 30% |

| OM-12 | 3500 | 70 | 58 | - | - | 50% | 17.8 | 12 | 50% | 4 | 8 | 30%* | 2.4 | 4.4 | 30%* | 0.8 | 2.6 | 30% |

| OM-13 | 4500 | 50% | 50% | 4.2 | 8 | 30%* | 2.4 | 4.8 | 30%* | 0.8 | 2.6 | 30% | ||||||

The start and run currents are measured at the maximum torque of the actuator.

*50% & 75% Duty Cycle available as an option depending on Actuator model, contact Sales for more information. Please see the 0M Series Wiring Diagrams for further wiring detail.

Optional Extras:

0M-A & 0M-1 0M-2 & Above

| Model | A (mm) | B (mm) | C (mm) | ISO 5211 Mounting | Female Drive | End Stops | Manual Override |

|---|---|---|---|---|---|---|---|

| OM-1 | 108 | 155 | - | FO3 / FO5 | 14mm Star | NO | Spanner Drive |

| OM-A | 130 | 200 | - | F05/FO7 | 17mm Star | NO | Allen Key Drive |

| OM-2 | 200 | 290 | 330 | FO7/F10 | 22mm Star | Yes | Hand wheel |

| OM-3 | 200 | 290 | 330 | FO7/F10 | 22mm Star | Yes | Hand wheel |

| OM-4 | 234 | 315 | 380 | F10/F12 | 36mm Star | Yes | Hand wheel |

| OM-5 | 234 | 315 | 380 | F10/F12 | 36mm Star | Yes | Hand wheel |

| OM-6 | 234 | 315 | 380 | F10/F12 | 36mm Star | Yes | Hand wheel |

| OM-7 | 234 | 420 | 520 | F14 | 36mm Star | Yes | Hand wheel |

| OM-8 | 234 | 420 | 520 | F14 | 36mm Star | Yes | Hand wheel |

| OM-9 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-10 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-11 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-12 | 260 | 590 | 540 | F16 | O 75mm Keyway | Yes | Hand wheel |

| OM-13 | F16/F25 | O 75mm Keyway | Yes | Hand wheel |