Features:

Size 3/8" to 2" BSP

Function Normally Closed (power to open)

Valve Operation Coupled Diaphragm

Body Forged Brass

Seat FKM

Pressure Range 0 to 10 BAR

Media Petrochemical

A high flow valve with brass forged body and stainless steel operator. Suitable for low head and zero head applications. available in various seat materials including Viton (standard), Silicone, Neoprene, EPDM & Nitrile (contact us for any seals other than standard). Liquids to 40cst viscosity. Standard coil is weatherproof to IP65 and has LED illuminated plug. Typical Applications include: Petrochemical, diesel farms, vacuum packaging, tank drain or low pressure service & general industry. Threads conform to ISO 7.1 Sealing Threads.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

For Installation and Maintenance instructions please click here or find in our References section under Valve Installation and Maintenance for Solenoid Valves.

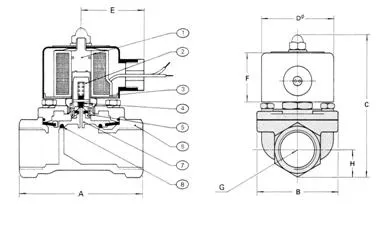

| Model | A | B | C | D | E | F | G | H | Weight Kg |

|---|---|---|---|---|---|---|---|---|---|

| B55-3-15 | 75 | 52 | 103 | 56 | 70 | 37 | 3/8 | 14.5 | 1 |

| B55-4-15 | 75 | 52 | 103 | 56 | 70 | 37 | 1/2 | 14.5 | 1 |

| B55-5-20 | 85 | 60 | 114 | 56 | 70 | 37 | 3/4 | 18 | 1.25 |

| B55-6-25 | 100 | 70 | 120 | 56 | 70 | 37 | 1 | 23 | 1.5 |

| B55-7-35 | 120 | 90 | 140 | 56 | 70 | 37 | 1-1/4 | 33 | 2.85 |

| B55-8-35 | 120 | 90 | 140 | 56 | 70 | 37 | 1-1/2 | 33 | 2.85 |

| B55-9-50 | 150 | 120 | 160 | 56 | 70 | 37 | 2 | 40.5 | 4.8 |

All dimensions in mm

.

Size 3/8" to 2" BSP

Function Normally Closed (power to open)

Valve Operation Coupled Diaphragm

Body Forged Brass

Seat FKM

Pressure Range 0 to 10 BAR

Media Petrochemical

What is a Normally Closed Brass Petrochemical Zero Differential Solenoid Valve?

A Brass Petrochemical Zero Differential Solenoid Valve is a valve whose body is constructed of Brass and does not need any pressure differential to operate (does not require a pressure differential from inlet to outlet to work). It is made for petrochemical applications such as diesel and any other media that is applicable. It utilizes an FKM diaphragm which is a great all higher performance elastomer. This covers a wide range of petrochemical applications and is very common within this sector.

How does a Brass Petrochemical Solenoid Valve work?

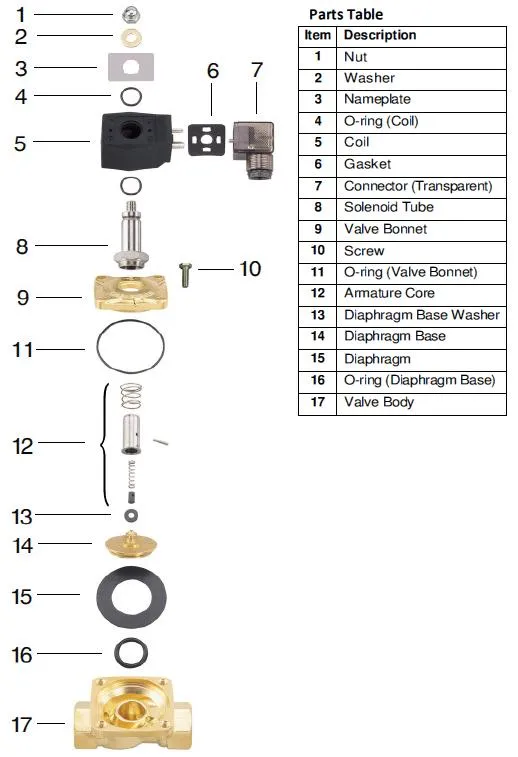

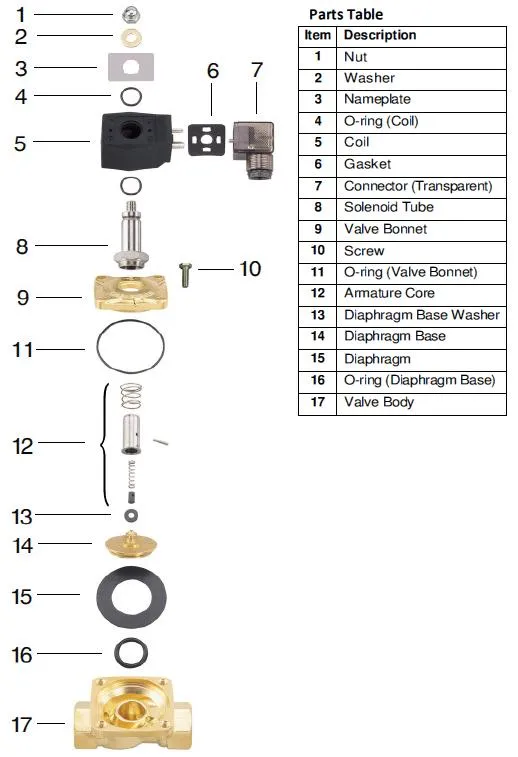

Solenoid valves can broadly be put into two categories; zero differential and differential. This relates to whether they need a differential pressure to operate. This Brass Petrochemical Solenoid Valve does not need a differential pressure to operate which means it is classified as a zero differential solenoid valve. Even whithin zero differential solenoid valves it can be broken down to two further categories; coupled diaphragm and direct acting. This valve is coupled diaphragm whereby the armature is coupled to the diaphragm so when the valve is operated it will lift the diaphragm off the seat allowing it to operate without a pressure differential. It does utilise any pressure differential that may be present to help push the diaphragm up into the cavity of the valve body to achieve a full flow. In its resting state which is normally closed (no power to the valve) the armature sits over the bleed off hole in the diaphragm leaving it closed on the seat of the valve (and not allowing flow through it). When the valve is powered on, an electromagnetic field created by the windings in the coil lifts the armature off this seat and slightly raises the diaphragm. If there is any pressure present in the valve it will bleed off the top of the diaphragm faster than it can come on (the bleed off hole is bigger than the bleed on hole) therefore the diaphragm lifts into the cavity of the valve and the media will flow through. The reverse happens when power is taken away from the valve.

How do I know that a Brass Petrochemical Solenoid Valve is the right valve for me?

The first thing to check is whether you want a Normally Closed (power to open) or Normally Open (power to close) solenoid valve. This valve is Normally Closed which is by far the more common of the two types. Next you will need to check the operating pressure and temperature of your system as well as the media type and make sure that the valve can handle these. From here you also need to check the port size of your valve and the voltage of your system. If the valve can satisfy all of the above then you should be a long way to getting the correct one (other items such as the external environment and where it is located can also influence the valve selection).

How long will my Normally Closed Brass Zero Differential Solenoid Valve last?

Like any valve this depends upon the usage case, duty cycle and external environment of the valve. The pressure, temperature and characteristics of the media (eg. is it corrosive, clean etc) will have a large bearing on how long your valve lasts. If your valve is cycling every second, 24 hours a day (ours are 100% duty rated which means they can do this as long as the heat can be dissipated) then its life will be shorter than one which is used once a day. The electrical supply to your coil can also determine the valve's life as voltage spikes can short the coils (the same as any electrical equipment).

What are typical uses of a Normally Closed Brass Petrochemical Solenoid Valve ?

This solenoid valve is very popular on fuel farms and other diesel/petrochemical applications. It does however have a wide range of other uses that it is suited as it does not require a pressure differential and the valve can handle a large range of media and pressures. The media for a solenoid valve must alway be clean as well as any suspended solids can block the holes in the diaphragm so this rules out contaminated media applications.

How do I install my Normally Closed Brass Petrochemical Solenoid Valve?

This Solenoid Valve must be installed with the correct direction of flow. On the side of the valve there is an arrow indicating the direction of flow, this must be followed otherwise the valve will not work. It is highly recommended that this solenoid valve be mounted with its coil up right (horizontal). The valve will work on any orientation however especially in larger sizes at very low pressure the weight of the armature connected to the diaphragm can cause it to come slightly off the seat and weep past. As the ends of this valve are female BSP threaded a male nipple will be screwed into this, thread tape or sealant will need to be used to achieve a bubble tight seal. Make sure when you wire the DIN Plug that it is facing down with a sufficient drip loop on your lead so water will not run down and into this which will cause it to fail.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days. You can rely on us to do everything to despatch your order the same day we receive it, this is what we do.

What warranty do I get?

We have been manufacturing Solenoid Valves for over 30 years so we have a lot of experience at making a great valve. All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all solenoid valves leave our warehouse tested (full material and testing certificates are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time barring any debris getting caught in the valve or power spikes causing the coil to fail.

Size 3/8" to 2" BSP

Function Normally Closed (power to open)

Valve Operation Coupled Diaphragm

Body Forged Brass

Seat FKM

Pressure Range 0 to 10 BAR

Media Petrochemical

A high flow valve with brass forged body and stainless steel operator. Suitable for low head and zero head applications. available in various seat materials including Viton (standard), Silicone, Neoprene, EPDM & Nitrile (contact us for any seals other than standard). Liquids to 40cst viscosity. Standard coil is weatherproof to IP65 and has LED illuminated plug. Typical Applications include: Petrochemical, diesel farms, vacuum packaging, tank drain or low pressure service & general industry. Threads conform to ISO 7.1 Sealing Threads.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

For Installation and Maintenance instructions please click here or find in our References section under Valve Installation and Maintenance for Solenoid Valves.

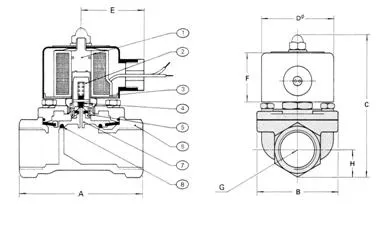

| Model | A | B | C | D | E | F | G | H | Weight Kg |

|---|---|---|---|---|---|---|---|---|---|

| B55-3-15 | 75 | 52 | 103 | 56 | 70 | 37 | 3/8 | 14.5 | 1 |

| B55-4-15 | 75 | 52 | 103 | 56 | 70 | 37 | 1/2 | 14.5 | 1 |

| B55-5-20 | 85 | 60 | 114 | 56 | 70 | 37 | 3/4 | 18 | 1.25 |

| B55-6-25 | 100 | 70 | 120 | 56 | 70 | 37 | 1 | 23 | 1.5 |

| B55-7-35 | 120 | 90 | 140 | 56 | 70 | 37 | 1-1/4 | 33 | 2.85 |

| B55-8-35 | 120 | 90 | 140 | 56 | 70 | 37 | 1-1/2 | 33 | 2.85 |

| B55-9-50 | 150 | 120 | 160 | 56 | 70 | 37 | 2 | 40.5 | 4.8 |

All dimensions in mm

.