Features:

Size 15mm to 100mm

Body 316 Stainless Steel

Seat RPTFE

Pressure 20 BAR @ ambient

Temperature -10°C to 180°C

Actuation Double Acting Pneumatic

Port L or T port

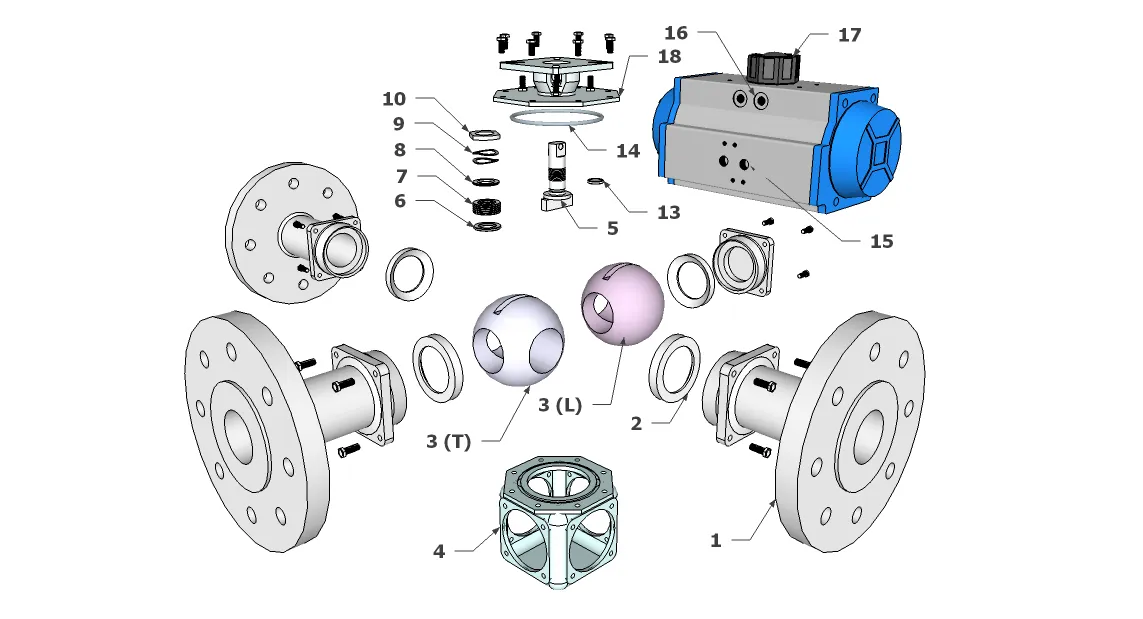

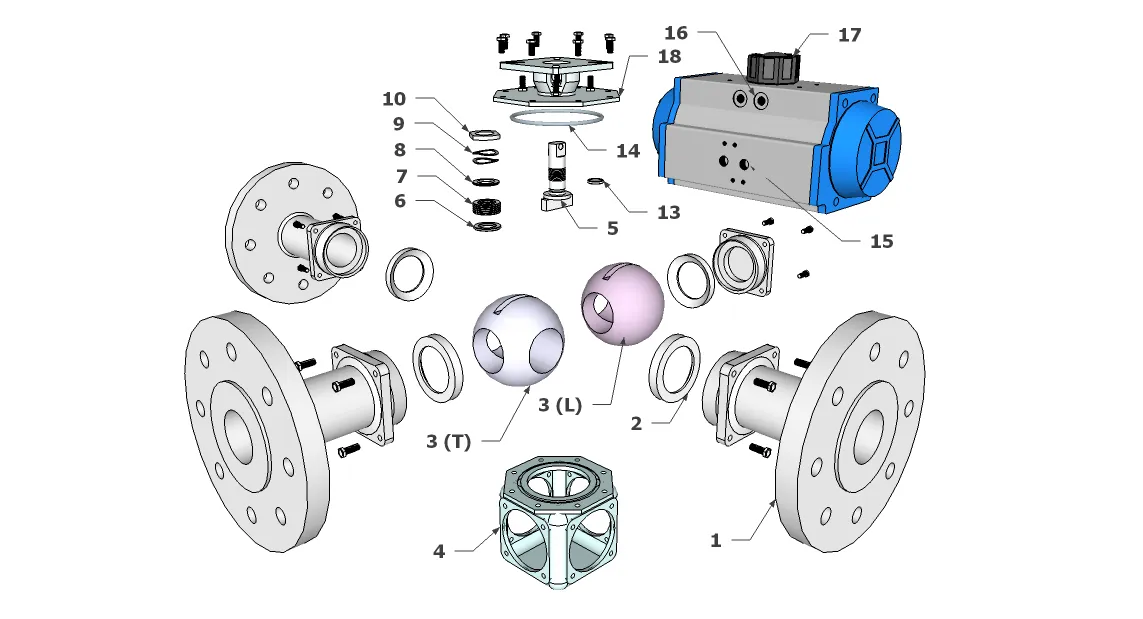

High performance 3 way full bore 316 Stainless Steel ball valve with ANSI 150 flanged connections and a double acting pneumatic actuator. Self adjusting stem packing assembly with belleville spring for temperature fluctuations and vibration. Pre drilled metric ISO5211 direct mounting pad to minimise any thermal transfer from valve to actuator. Reinforced PTFE seats for temperatures up to 180°C. Anodized aluminium rack and pinion actuator with visual indicator, namur interface and stop adjustments. Typical applications include water treatment, chemical, marine, petrochemical and general industry.

| L Port | T Port |

|---|---|

|

|

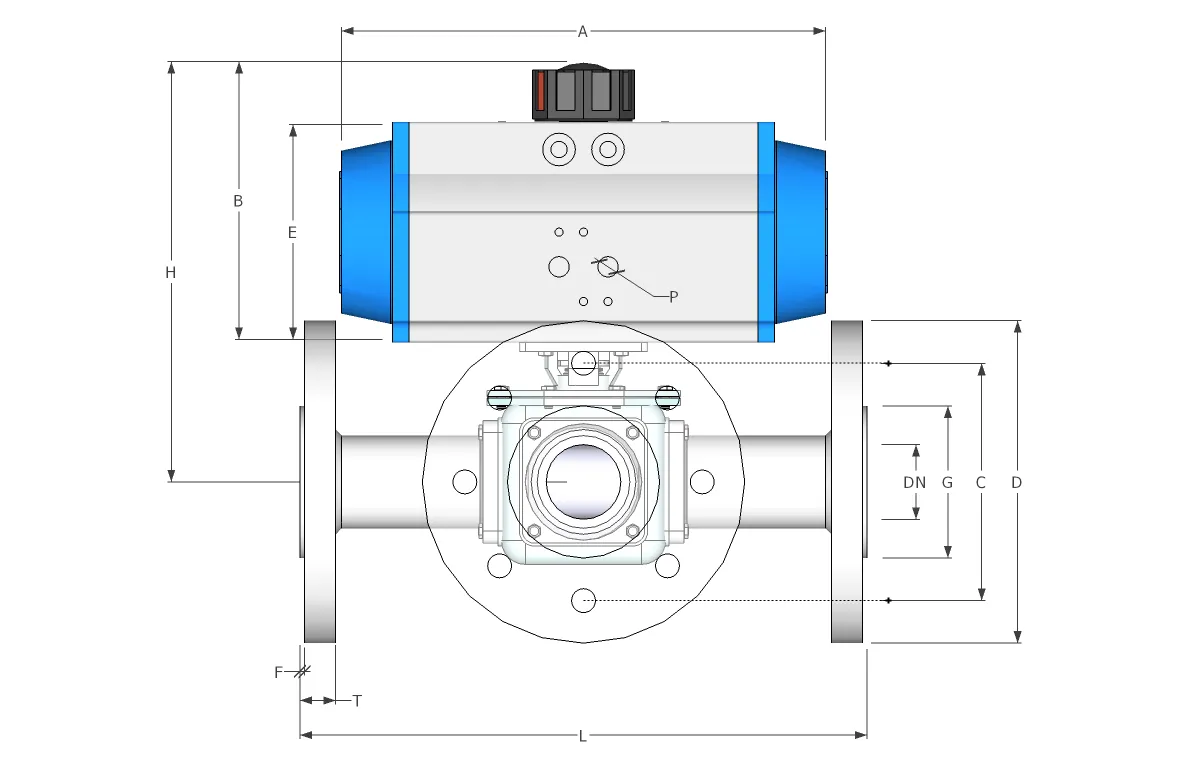

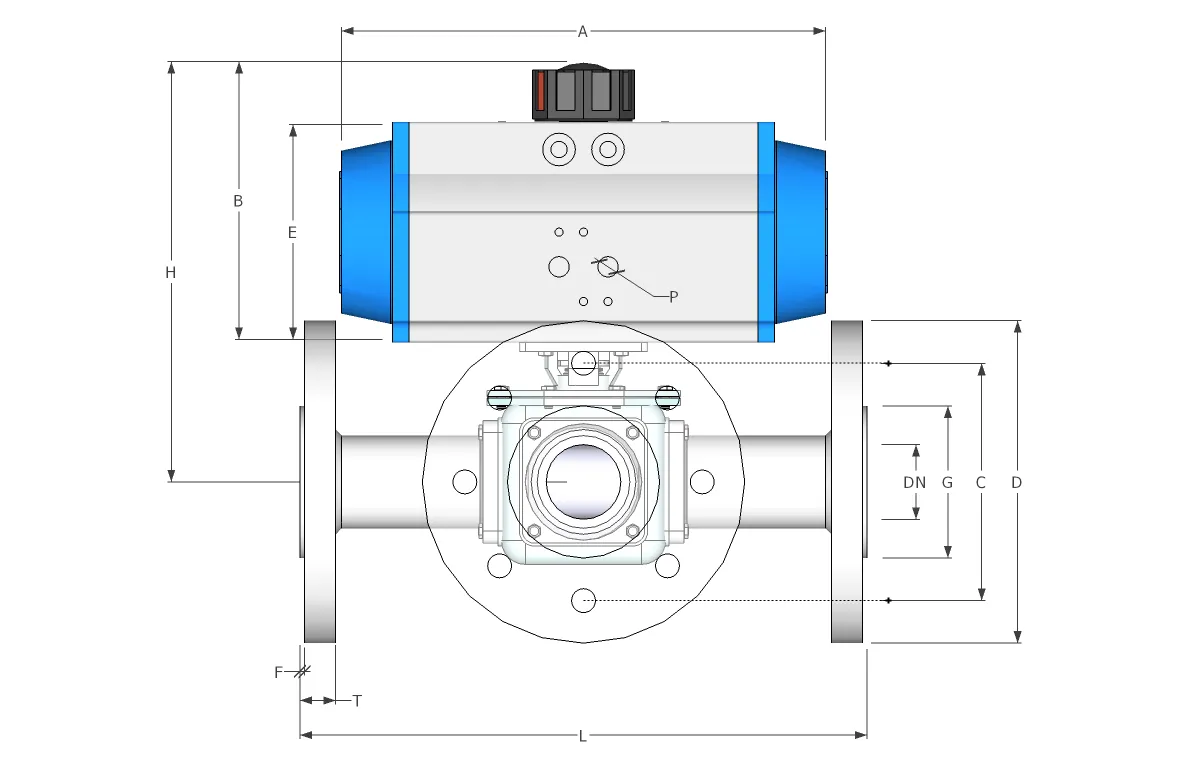

| DN | Actuator | A | B | C | D | E | F | G | H | L | T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | DA50 | 138 | 90 | 60.5 | 89 | 70 | 2 | 35 | 134.5 | 152 | 11 |

| 20 | DA63 | 162 | 100 | 70 | 98 | 80 | 2 | 43 | 150 | 167 | 11 |

| 25 | DA63 | 162 | 100 | 79.5 | 108 | 80 | 2 | 51 | 155 | 180 | 12 |

| 32 | DA75 | 208 | 117 | 89 | 117 | 97 | 2 | 64 | 175.5 | 190 | 13 |

| 40 | DA88 | 245 | 136 | 98.5 | 127 | 116 | 2 | 73 | 180.5 | 212 | 15 |

| 50 | DA100 | 266 | 142 | 120.5 | 152 | 122 | 2 | 92 | 212 | 230 | 16 |

| 65 | DA115 | 310 | 172 | 139.5 | 178 | 142 | 2 | 105 | 231 | 290 | 18 |

| 80 | DA125 | 340 | 184 | 152.5 | 190 | 154 | 2 | 127 | 267.25 | 310 | 19 |

| 100 | DA145 | 401 | 209 | 190.5 | 229 | 179 | 2 | 157 | 298.5 | 350 | 24 |

All dimensions in mm unless shown otherwise.

Size 15mm to 100mm

Body 316 Stainless Steel

Seat RPTFE

Pressure 20 BAR @ ambient

Temperature -10°C to 180°C

Actuation Double Acting Pneumatic

Port L or T port

What is a 3 Way Flanged Stainless Steel Double Acting Pneumatic Ball Valve?

A three way stainless steel flanged double acting ball valve operates on the same principle as a two way, but instead of a complete isolation or completely open (2 states, closed or open) it will have one line open and one line closed. It is important to note that during its 90 degree turn from one line to another there is a point where all lines are partially open to each other even though this is for a very short period of time (the time for one cycle depends upon the size of the actuator, your air pressure and 5/2 valve size but is usually a second or so in the smaller sizes and a few seconds in the bigger sizes). The 3 way ball valve itself is made of cast stainless steel (CF8M) with a polished stainless steel ball and a direct mounted anodised aluminium rack and pinion actuator. The connection is ANSI 150 flanged but other flange standards are available upon request. The size of the actuator will get bigger with the size of the valves as the torque required increases. We match all of our actuators with at least a 30% safety margin in torque.

How does a 3 Way Flanged Stainless Steel Double Acting Pneumatic Ball Valve work?

The 3 way flanged ball valve will work by the double acting actuator rotating the ball 90 degrees in the valve. This will be in a clockwise or anticlockwise direction depending upon the actuator involved (ours usually open anti clockwise). The actuator itself is controlled by a 5/2 valve (either solenoid or manual) which will put the air in one side of the pistons and exhaust it out of the other side allowing the racks to rotate pinion. This will then turn the ball 90 degrees as the actuator is mated to the shaft of the ball valve, switching the ports to the other configuration. This is the same operation as a threaded 3 way double acting ball valve however this connection is flanged and it is full bore so there is no restriction inside the unit.

How long will my Flanged 3 Way Stainless Steel Double Acting Ball Valve last?

This depends upon the usage case of your valve, its environment, media, supply air cleanliness and how many times it is cycled. For instance if it is on a clean media, in a clean environment and not cycled regularly the life will be decades. If it is on a corrosive media and in a dry application with a high cycle rate the life will be much shorter. We conduct regular lab testing and 30,000 cycles is a reasonable life cycle depending upon the application. The actuator's life will depend upon how clean and dry the supply air is (the air that makes the actuator operate) however we regularly lab test these to over 800,000 cycles. Install a basic air filter if you are not sure about the quality of your air, we have pneumatic actuators that have been in operation for decades.

How do I install a Flanged 3 Way Stainless Steel Double Acting Ball Valve?

This really depends upon the application it is going into. As this 3 way valve is flanged ANSI 150 it will need to be mated to other flanges of the same standard. A gasket should be fitted between the two mating flanges to ensure a positive seal. The bolts of the flanges should then be hand tightened and then finished with a torque wrench to the setting of that flange standard. They should be tightened in a diagonal direction around the flange diameter. The actuator can accommodate a namur solenoid valve which is a very popular configuration (the 5/2 control valve bolts directly onto the actuator with an o-ring face seal on the back of the valve) or just a standalone 5/2 valve. If you are using a stand alone 5/2 valve the air lines will need to be run from here into the ports on the actuator (remember the longer the run the slower the operation unless you use quick exhaust valves near the actuator).

What are typical uses of a three way flanged stainless steel double acting ball valve?

These three way double acting flanged ball valves are used on a wide variety of applications. Everything from the food industry, power generation, mining and irrigation. The common theme though is where either a diversion (switching from one line to another) or isolation of one line to change over to another is used. The media can range from water, steam all the way through to corrosive chemicals that are compatible with the materials of the valve. Being double acting they are not really used on fail safe applications as you would want a spring return actuator in this instance (if you lose air the mechanical spring will turn the valve to your fail safe position). Been flanged it makes them easy to remove from pipework without unscrewing the lengths of pipe.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 15mm to 100mm

Body 316 Stainless Steel

Seat RPTFE

Pressure 20 BAR @ ambient

Temperature -10°C to 180°C

Actuation Double Acting Pneumatic

Port L or T port

High performance 3 way full bore 316 Stainless Steel ball valve with ANSI 150 flanged connections and a double acting pneumatic actuator. Self adjusting stem packing assembly with belleville spring for temperature fluctuations and vibration. Pre drilled metric ISO5211 direct mounting pad to minimise any thermal transfer from valve to actuator. Reinforced PTFE seats for temperatures up to 180°C. Anodized aluminium rack and pinion actuator with visual indicator, namur interface and stop adjustments. Typical applications include water treatment, chemical, marine, petrochemical and general industry.

| L Port | T Port |

|---|---|

|

|

| DN | Actuator | A | B | C | D | E | F | G | H | L | T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | DA50 | 138 | 90 | 60.5 | 89 | 70 | 2 | 35 | 134.5 | 152 | 11 |

| 20 | DA63 | 162 | 100 | 70 | 98 | 80 | 2 | 43 | 150 | 167 | 11 |

| 25 | DA63 | 162 | 100 | 79.5 | 108 | 80 | 2 | 51 | 155 | 180 | 12 |

| 32 | DA75 | 208 | 117 | 89 | 117 | 97 | 2 | 64 | 175.5 | 190 | 13 |

| 40 | DA88 | 245 | 136 | 98.5 | 127 | 116 | 2 | 73 | 180.5 | 212 | 15 |

| 50 | DA100 | 266 | 142 | 120.5 | 152 | 122 | 2 | 92 | 212 | 230 | 16 |

| 65 | DA115 | 310 | 172 | 139.5 | 178 | 142 | 2 | 105 | 231 | 290 | 18 |

| 80 | DA125 | 340 | 184 | 152.5 | 190 | 154 | 2 | 127 | 267.25 | 310 | 19 |

| 100 | DA145 | 401 | 209 | 190.5 | 229 | 179 | 2 | 157 | 298.5 | 350 | 24 |

All dimensions in mm unless shown otherwise.