Features:

Size 15mm to 100mm

Body UV Stabalised PVC

Mesh Polypropylene

Pressure Range 0 to 10 BAR

Factory Accredited CE, ISO 9001, TUV, WRAS

UV Stabalised PVC Y Strainer with Solvent Weld End (suit schedule 80). Great for water treatment and aquaculture or anywhere in PVC pipe where a strainer is required.

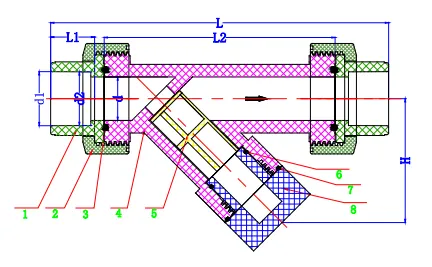

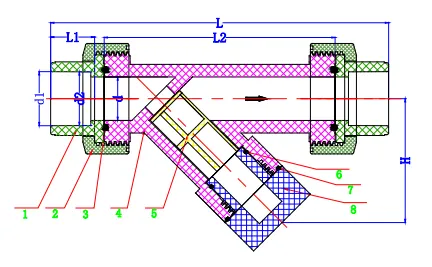

| Size | d | d1 | d2 | L | L1 | L2 | H |

|---|---|---|---|---|---|---|---|

| 1/2" | 15 | 21.4 | 21.25 | 174 | 22.3 | 110 | 55 |

| 3/4" | 20 | 26.75 | 26.58 | 195 | 26 | 125 | 66 |

| 1" | 25 | 33.52 | 33.28 | 202 | 29 | 138 | 75 |

| 1 1/4" | 32 | 42.28 | 42.05 | 233 | 32.5 | 149 | 82 |

| 1 1/2" | 40 | 48.4 | 48.12 | 276 | 32.5 | 189 | 105 |

| 2" | 50 | 60.45 | 60.18 | 311 | 38.5 | 222 | 135 |

| 2 1/2" | 63 | 73.3 | 72.85 | 410 | 64.5 | 268 | 168 |

| 3" | 75 | 89.25 | 88.7 | 485 | 70 | 330 | 220 |

| 4" | 90 | 114.6 | 114.1 | 615 | 84 | 420 | 300 |

All dimensions in mm unless shown otherwise.

| Number | Part Name | Raw Material | QTY |

|---|---|---|---|

| 1 | Socket End | UPVC | 2 |

| 2 | Cap Nut | UPVC | 2 |

| 3,6,7 | O-Ring | EPDM | 4 |

| 4 | Body | PVC | 1 |

| 5 | Filter Net | Polypropylene | 1 |

| 8 | Cock | UPVC | 1 |

Size 15mm to 100mm

Body UV Stabalised PVC

Mesh Polypropylene

Pressure Range 0 to 10 BAR

Factory Accredited CE, ISO 9001, TUV, WRAS

What is a PVC Y Strainer?

A PVC Y Strainer is a strainer that is made out of a UV Stabalised Clear PVC Housing which contains a 316 Polypropylene strainer element within it that sits on a 60 degree angle. This stems the nickname (trade name) as it forms a Y in the shape of the unit. The entry and exit have a solvent weld connection and the strainer element can be accessed while the unit is inline by removing unscrewing the cap at the bottom of the Y. This cap utilises a EPDM oring to form a seal between the cap and body. These Strainers are used inline to protect downstream equipment from suspended solids or debris of a size that the strainer element will catch.

How does a PVC Y Strainer work?

The media enters the strainer and is then carried to the filter element inside the strainer. The exit is on the other side of the strainer element so it will flow through the strainer element while any particle will be caught in the strainer element as it cant fit through the holes. These are a very simple device as they have no moving parts and very valuable to all process lines as it offers a form of protection, quite often the first layer of defence. It is standard practice to use a strainer upstream in all process lines.

How do I maintain a PVC Y Strainer?

Really the only maintenance that is required on a Y Strainer is to clean the element. How regularly this occurs depends upon how dirty the media is. There are some indicators that the element needs to be clean usually by a bigger than normal drop of pressure or a decrease in velocity of the media downstream from the strainer. For maintenance the line must first be isolated and pressure removed from it. To clean the element the cap on the bottom of the Y Strainer needs to be removed. This will then allow the element to be removed from the strainer and cleaned. It can then be reinstalled and pressure returned to the line.

How do I install a PVC Y Strainer?

There are really only two steps to follow to ensure a good installation of these flanged Y strainers. The first and most important is to ensure the direction of flow is followed. This is indicated by an arrow on the side of the housing. Next it is best to have the bottom of the Y strainer facing down. This is so any dirt or debris collected will sit at the bottom of the strainer element and will be very easy to remove when the bung is opened. It is best to install some sort of isolation valve before the strainer so the line can be isolated while maintenance occurs on the strainer. As this is PVC it is best to use a PVC ball valve or PVC butterfly valve for this isolation.

How long will my PVC Y Strainer Last?

These will last for a very long time as they are made from UV Stabalised PVC and are very durable. The actual length of time will depend upon the media compatibility and how clean it is. Also the external environment will have some influence on the unit's lifetime.

What are typical uses of a PVC Y Strainer?

As these Strainers are made of PVC they are commonly used on chemicals that are compatible with these materials of construction. The seal and filter element materials must also be taken into consideration when matching it to the media. Many users also use them on water or inert media where they wish to see inside the strainer, as the body is clear it lets you visually check inside the strainer for flow and debris.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all Strainers leave our warehouse tested and inspected so there are rarely any issues. Also once your Strainer is in and operating it will most likely continue to do so for a very long time barring any external factors and it is kept clean.

Size 15mm to 100mm

Body UV Stabalised PVC

Mesh Polypropylene

Pressure Range 0 to 10 BAR

Factory Accredited CE, ISO 9001, TUV, WRAS

UV Stabalised PVC Y Strainer with Solvent Weld End (suit schedule 80). Great for water treatment and aquaculture or anywhere in PVC pipe where a strainer is required.

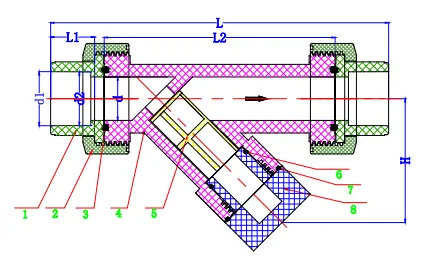

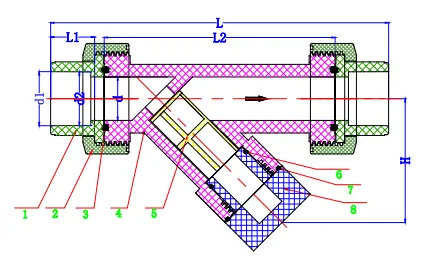

| Size | d | d1 | d2 | L | L1 | L2 | H |

|---|---|---|---|---|---|---|---|

| 1/2" | 15 | 21.4 | 21.25 | 174 | 22.3 | 110 | 55 |

| 3/4" | 20 | 26.75 | 26.58 | 195 | 26 | 125 | 66 |

| 1" | 25 | 33.52 | 33.28 | 202 | 29 | 138 | 75 |

| 1 1/4" | 32 | 42.28 | 42.05 | 233 | 32.5 | 149 | 82 |

| 1 1/2" | 40 | 48.4 | 48.12 | 276 | 32.5 | 189 | 105 |

| 2" | 50 | 60.45 | 60.18 | 311 | 38.5 | 222 | 135 |

| 2 1/2" | 63 | 73.3 | 72.85 | 410 | 64.5 | 268 | 168 |

| 3" | 75 | 89.25 | 88.7 | 485 | 70 | 330 | 220 |

| 4" | 90 | 114.6 | 114.1 | 615 | 84 | 420 | 300 |

All dimensions in mm unless shown otherwise.

| Number | Part Name | Raw Material | QTY |

|---|---|---|---|

| 1 | Socket End | UPVC | 2 |

| 2 | Cap Nut | UPVC | 2 |

| 3,6,7 | O-Ring | EPDM | 4 |

| 4 | Body | PVC | 1 |

| 5 | Filter Net | Polypropylene | 1 |

| 8 | Cock | UPVC | 1 |