Features:

Size 50mm to 600mm

Body FBE Coated Ductile Iron

Seat EPDM

Disc 316 Stainless Steel

Pressure Up to 16 BAR (depending upon size)

Actuation Lever or Gearbox

Watermark, StandardsMark & WSAA Approved

The BFL series has a lugged (in a choice of Table E, Table D/AS4087 PN16 or Ansi 150) ductile iron body, 316 S.S disc and an EPDM seat making them suited to a wide range of general water applications. These are operated by either a lockable lever & notch plate or gear box. The unique bonded catridge design gives them a longer life span, allowing vacuum to be run through them and makes them replaceable if ever the need should arise. Common applications include water trucks, irrigation, cement hoppers and other industrial applications. These are Watermark, Standards Mark and WSAA (Water Service Association of Australia) certified. If size is above 600mm, double flanged valves are used. Please contact us for details.

| Model | Size (mm) | Pressure Range | Temperature | Square drive size | ISO Mtg | Torque (Nm) |

|---|---|---|---|---|---|---|

| BFL50-L-E | 50 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 9mm | F05 | 12.5 |

| BFL65-L-E | 65 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 9mm | F05 | 16.5 |

| BFL80-L-E | 80 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 9mm | F05 | 24 |

| BFL100-L-E | 100 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 11mm | F07 | 41 |

| BFL125-L-E | 125 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 14mm | F07 | 56 |

| BFL150-L-E | 150 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 14mm | F07 | 95 |

| BFL200-L-E | 200 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 17mm | F10 | 185 |

| BFL250-L-E | 250 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 22mm | F10 | 290 |

| BFL300-L-E | 300 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 22mm | F10 | 340 |

| BFL350-G-E | 350 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 22mm | F10 | 824 |

| BFL400-G-E | 400 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 22mm | F14 | 1073 |

| BFL450-G-E | 450 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 27mm | F14 | 1602 |

| BFL500-G-E | 500 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 27mm | F14 | 1953 |

| BFL600-G-E | 600 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 36mm | F16 | 3561 |

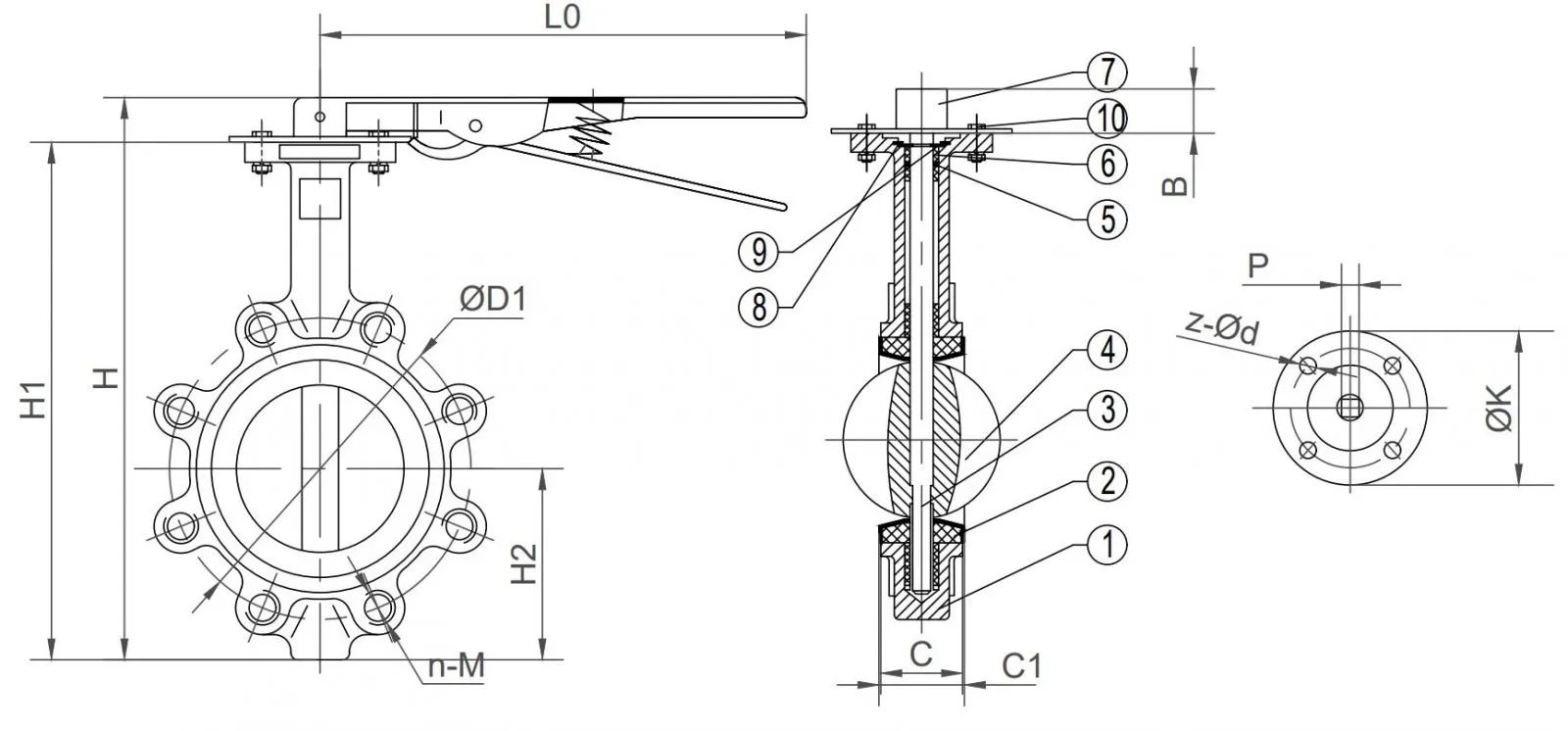

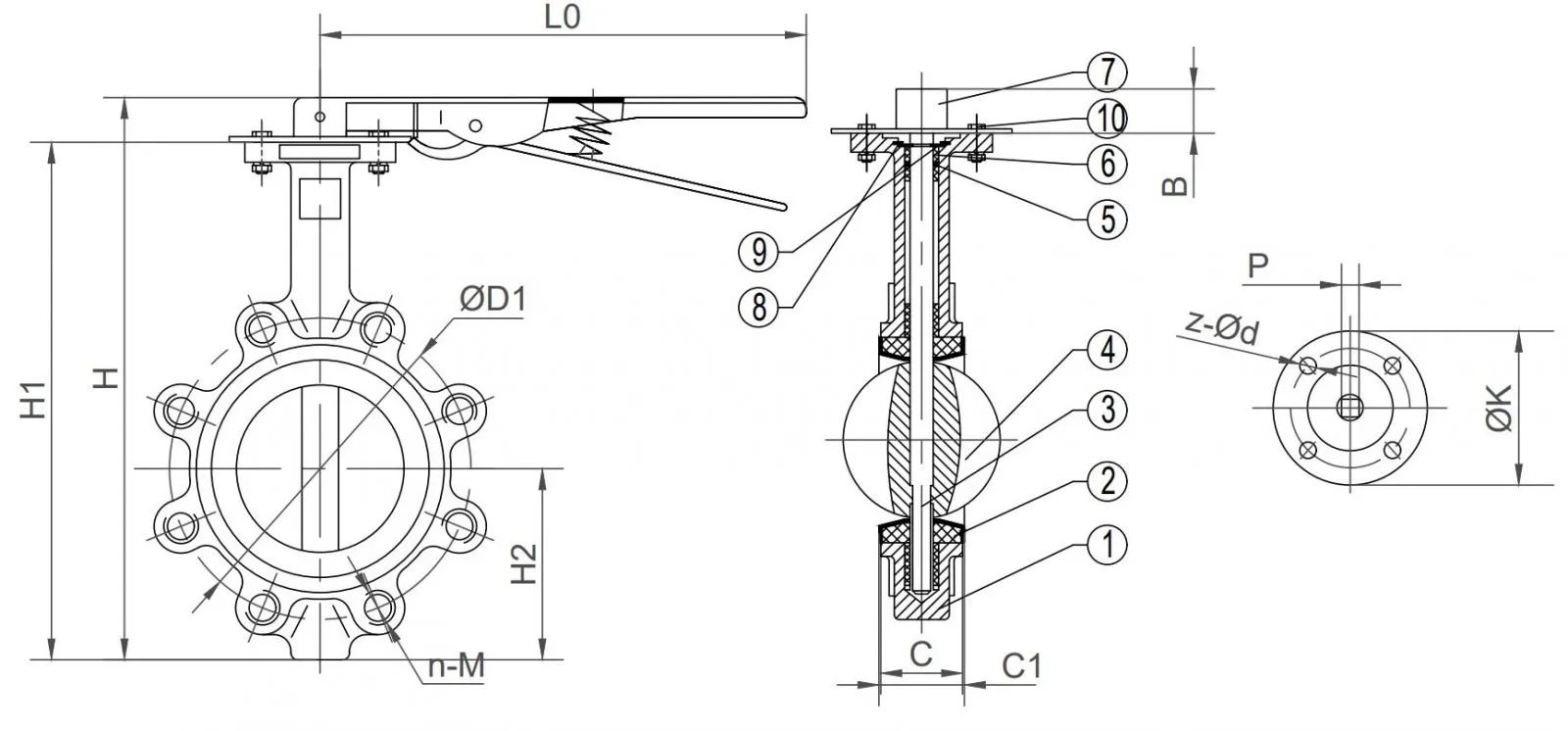

Sizes 50mm to 300mm

| Model | Size (DN) | H | H1 | H2 | C | C1 | B | L0 | P | AS4087 PN16 | AS2129 Table E | ANSI 150 | ØK | ISO pad | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | n-M | D1 | n-M | D1 | n-M | ||||||||||||

| BFL50-L-E | 50 | 255 | 225 | 70 | 42 | 46.1 | 30 | 262 | 9 | 114 | 4-M16 | 114 | 4-M16 | 120.5 | 4-5/8" | 77 | F05 |

| BFL65-L-E | 65 | 275 | 245 | 77 | 44.7 | 49.1 | 30 | 262 | 9 | 127 | 4-M16 | 127 | 4-M16 | 139.5 | 4-5/8" | 77 | F05 |

| BFL80-L-E | 80 | 291 | 261 | 87 | 45.2 | 48.4 | 30 | 262 | 9 | 146 | 4-M16 | 146 | 4-M16 | 152.5 | 4-5/8" | 77 | F05 |

| BFL100-L-E | 100 | 335 | 305 | 112 | 52.1 | 55.3 | 30 | 262 | 11 | 178 | 4-M16 | 178 | 8-M16 | 190.5 | 8-5/8" | 90 | F07 |

| BFL125-L-E | 125 | 362 | 332 | 128 | 54.4 | 58.8 | 30 | 262 | 14 | 210 | 8-M16 | 210 | 8-M16 | 216 | 8-3/4" | 90 | F07 |

| BFL150-L-E | 150 | 391 | 361 | 143 | 55.8 | 59.1 | 30 | 262 | 14 | 235 | 8-M16 | 235 | 8-M20 | 241.5 | 8-3/4" | 90 | F07 |

| BFL200-L-E | 200 | 463 | 423 | 173 | 60.6 | 64.1 | 40 | 348 | 17 | 292 | 8-M16 | 292 | 8-M20 | 298.5 | 8-3/4" | 125 | F10 |

| BFL250-L-E | 250 | 539 | 499 | 210 | 65.6 | 71.8 | 40 | 510 | 22 | 356 | 8-M20 | 356 | 12-M20 | 362 | 12-7/8" | 125 | F10 |

| BFL300-L-E | 300 | 618 | 578 | 244 | 76.9 | 81 | 40 | 510 | 22 | 406 | 12-M20 | 406 | 12-M24 | 432 | 12-7/8" | 125 | F10 |

C dimension relates to body thickness & C1 relates to seat thickness.

All dimensions in mm unless shown otherwise.

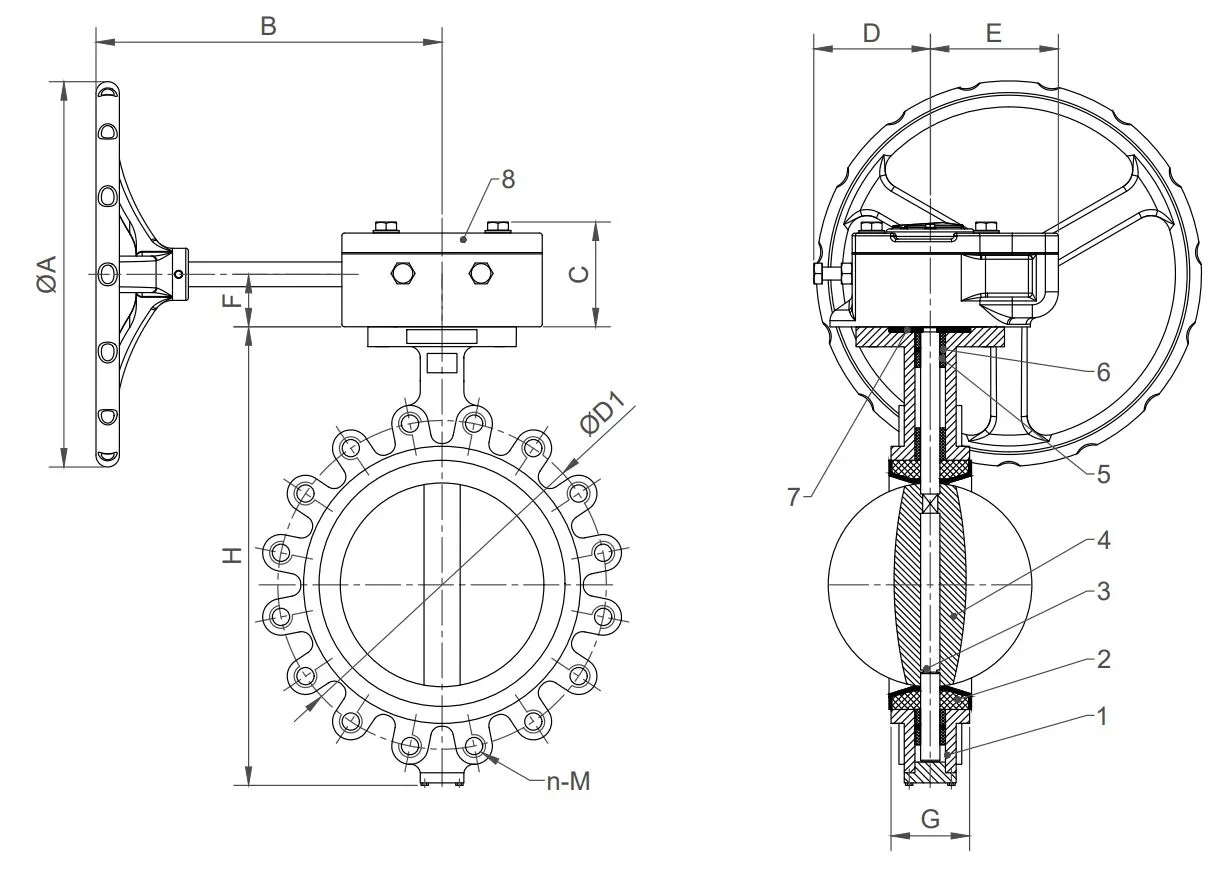

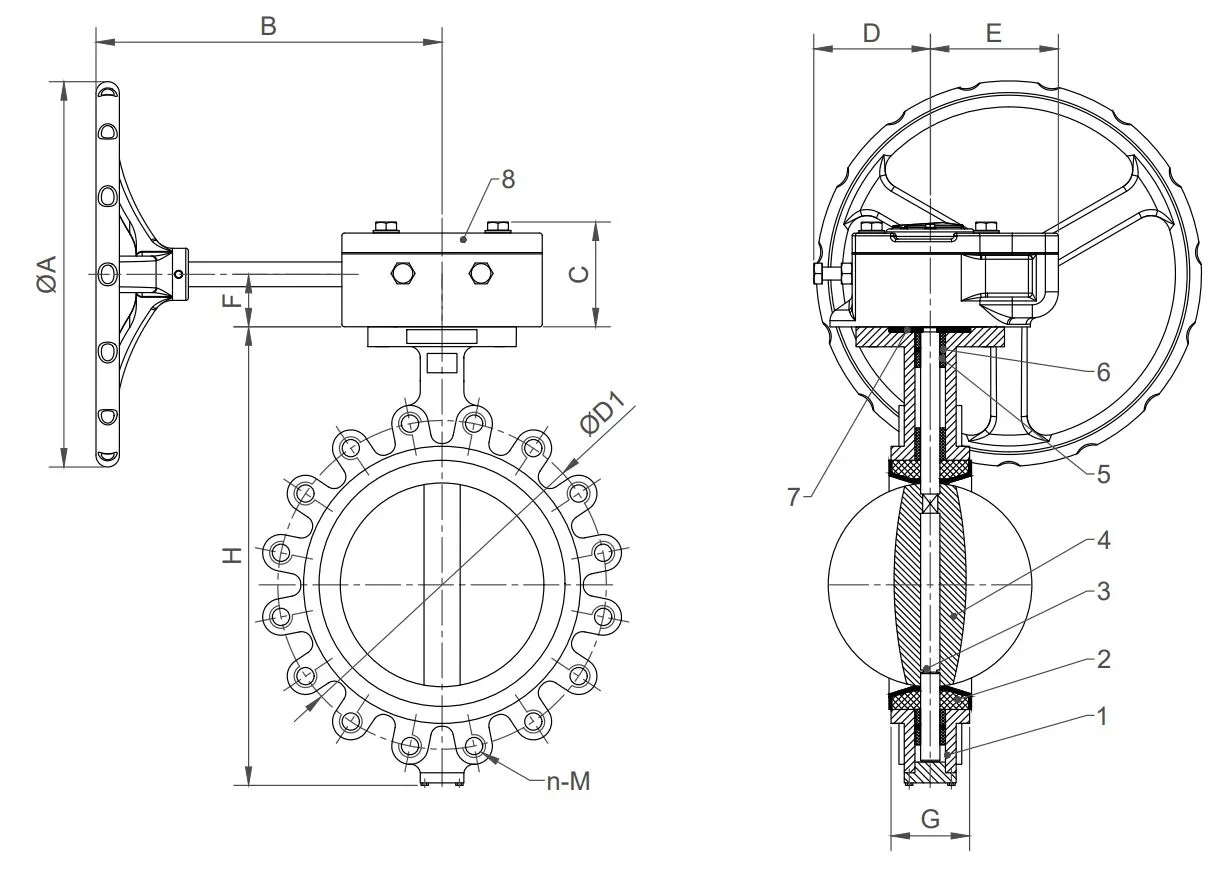

Sizes 350mm to 600mm

| Model | Size (DN) | Gearbox | ØA | B | C | D | E | F | G | H | L | AS2129 Table E | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | n-M | ||||||||||||

| BFL350-G-E | 350 | GB3 | 300 | 266 | 80.3 | 89.5 | 98.5 | 41 | 76.5 | 635 | 45 | 470 | 12-M24 |

| BFL400-G-E | 400 | GB4 | 350 | 330.5 | 110.7 | 107.5 | 120 | 49 | 86.5 | 709 | 51.2 | 521 | 12-M24 |

| BFL450-G-E | 450 | GB4 | 350 | 330.5 | 110.7 | 107.5 | 120 | 49 | 105.6 | 750 | 51.2 | 584 | 16-M24 |

| BFL500-G-E | 500 | GB4 | 350 | 330.5 | 110.7 | 107.5 | 120 | 49 | 131.8 | 841 | 64.2 | 641 | 16-M24 |

| BFL600-G-E | 600 | GB5 | 400 | 327.5 | 119.1 | 112.7 | 160 | 55 | 152 | 1021 | 70.2 | 756 | 16-M30 |

All dimensions in mm unless shown otherwise

Sizes 50mm to 300mm

| Item | Part | Material | Grade | Build & Test Standard |

|---|---|---|---|---|

| 1 | Body | Ductile Iron (FBE Coated) | AS1831500-7 | ASTM A536 |

| 2 | Seat | EPDM | 70 IRHD | - |

| 3 | Shaft | Stainless Steel | SS431 | ASTM A370 |

| 4 | Disc | Stainless Steel | CF8M | ASTM A370 |

| 5 | Bushing | Polymers | PTFE | - |

| 6 | O Ring | NBR | 70 IRHD | - |

| 7 | Handle | Ductile Iron (FBE Coated) | AS1831500-7 | ASTM A536 |

| 8 | Circlip | Stainless Steel | SS316 | ASTM A370 |

| 9 | Card | Stainless Steel | SS316 | ASTM A370 |

| 10 | Bolts & Nuts | Stainless Steel | A4-70 | - |

Sizes 350mm to 600mm

| Item | Part | Material | Grade | Build & Test Standard |

|---|---|---|---|---|

| 1 | Body | Ductile Iron (FBE Coated) | AS1831500-7 | ASTM A536 |

| 2 | Seat | EPDM | 70 IRHD | - |

| 3 | Shaft | Stainless Steel | SS431 | ASTM A370 |

| 4 | Disc | Stainless Steel | CF8M | ASTM A370 |

| 5 | Bushing | Polymers | PTFE | - |

| 6 | O Ring | NBR | 70 IRHD | - |

| 7 | Card | Stainless Steel | SS316 | ASTM A370 |

| 8 | Gearbox | Cast Iron |

Size 50mm to 600mm

Body FBE Coated Ductile Iron

Seat EPDM

Disc 316 Stainless Steel

Pressure Up to 16 BAR (depending upon size)

Actuation Lever or Gearbox

Watermark, StandardsMark & WSAA Approved

What is a Lugged Butterfly Valve?

A lugged butterfly valve is a butterfly valve that is designed to have bolts threaded into the body of the valve to hold it in place. In this case we are talking about ductile iron (similar to cast iron but better advantages in terms of strength, elongation & life) center line wafer butterfly valves. The center line refers to the location of the disc and shaft in relation to the body (there are other kinds of butterfly valves such as double & triple offset) where it is precisely in the middle. They are Watermark and Standards mark approved.

How does a Lugged Butterfly Valve work?

A butterfly valve works by the shaft rotating 90 degrees which will take the position of the disc in the flow from open to close (or vice versa). When it is closed a seal will be formed between the disc and the seat effectively stopping the flow of the media. When it is opened again the disc comes away from the seat and when it is fully open sits side (smallest surface area facing) on to the direction of the upstream flow. This 90 degree turn will take place from either a lockable handle (has a notch plate to stop at different positions within the 90 degree turn) or a gear box. Both have stops to prevent turning the valve past 90 degrees.

How long will my Lugged Butterfly Valve last?

Like any valve this depends upon the usage case of your butterfly valve, its environment, media and how many times it is cycled. For instance if it is on a clean wet media, in a clean environment and not cycled regularly the life will be decades. If it is on a corrosive media and in a dry application with a high cycle rate the life will be much shorter. We conduct regular lab testing and 6,000 cycles is a reasonable life cycle depending upon the application. One advantage of this design is that the seat is replaceable and available as a repair kit.

How do I install a Lugged Butterfly Valve?

These lugged butterfly valves are held into place by threaded bolts which attach the valve to the flanges or headwall. The seat of the valve also forms the gasket on the flanges so there is no need for a secondary gasket. The bolts should be tightened in a diagonal shape to avoid over tightening in one area. For a full list of instructions please visit our butterfly valve installation & maintenance guide.

What are typical uses of a Lugged Butterfly Valve?

These are very common in the water industry especially because most of our models hold a Watermark and Standards mark approval. They are also used for general purpose applications as long as the media, temperature and pressure are compatible. One main advantage of butterfly valves is they are relatively cheap compared to their size if you are comparing to another valve type (eg. ball valve).

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API 598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 50mm to 600mm

Body FBE Coated Ductile Iron

Seat EPDM

Disc 316 Stainless Steel

Pressure Up to 16 BAR (depending upon size)

Actuation Lever or Gearbox

Watermark, StandardsMark & WSAA Approved

The BFL series has a lugged (in a choice of Table E, Table D/AS4087 PN16 or Ansi 150) ductile iron body, 316 S.S disc and an EPDM seat making them suited to a wide range of general water applications. These are operated by either a lockable lever & notch plate or gear box. The unique bonded catridge design gives them a longer life span, allowing vacuum to be run through them and makes them replaceable if ever the need should arise. Common applications include water trucks, irrigation, cement hoppers and other industrial applications. These are Watermark, Standards Mark and WSAA (Water Service Association of Australia) certified. If size is above 600mm, double flanged valves are used. Please contact us for details.

| Model | Size (mm) | Pressure Range | Temperature | Square drive size | ISO Mtg | Torque (Nm) |

|---|---|---|---|---|---|---|

| BFL50-L-E | 50 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 9mm | F05 | 12.5 |

| BFL65-L-E | 65 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 9mm | F05 | 16.5 |

| BFL80-L-E | 80 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 9mm | F05 | 24 |

| BFL100-L-E | 100 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 11mm | F07 | 41 |

| BFL125-L-E | 125 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 14mm | F07 | 56 |

| BFL150-L-E | 150 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 14mm | F07 | 95 |

| BFL200-L-E | 200 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 17mm | F10 | 185 |

| BFL250-L-E | 250 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 22mm | F10 | 290 |

| BFL300-L-E | 300 | Vacuum to 16 Bar | -20°C to 90°C (40°C Potable) | 22mm | F10 | 340 |

| BFL350-G-E | 350 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 22mm | F10 | 824 |

| BFL400-G-E | 400 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 22mm | F14 | 1073 |

| BFL450-G-E | 450 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 27mm | F14 | 1602 |

| BFL500-G-E | 500 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 27mm | F14 | 1953 |

| BFL600-G-E | 600 | Vacuum to 10 Bar | -20°C to 90°C (40°C Potable) | 36mm | F16 | 3561 |

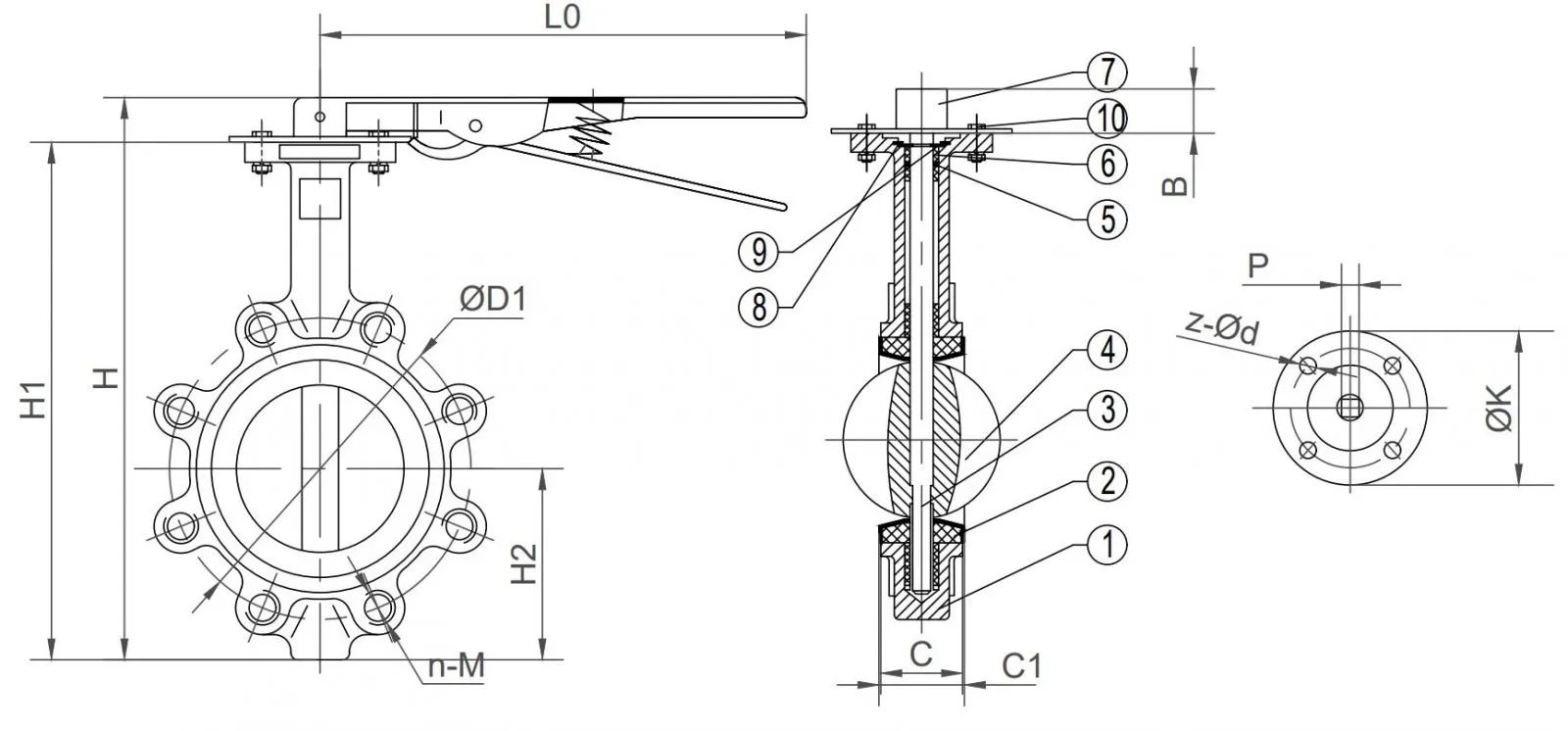

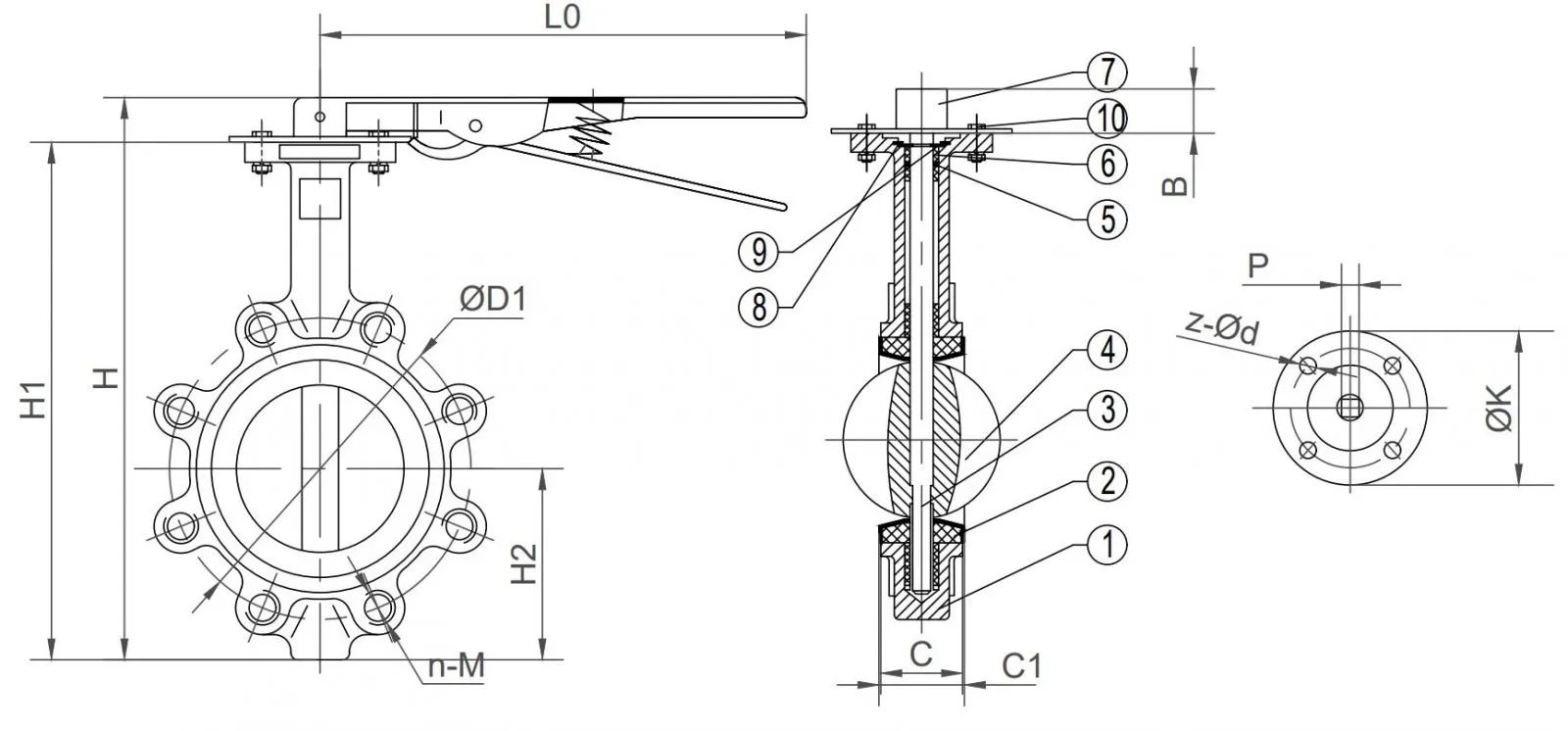

Sizes 50mm to 300mm

| Model | Size (DN) | H | H1 | H2 | C | C1 | B | L0 | P | AS4087 PN16 | AS2129 Table E | ANSI 150 | ØK | ISO pad | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | n-M | D1 | n-M | D1 | n-M | ||||||||||||

| BFL50-L-E | 50 | 255 | 225 | 70 | 42 | 46.1 | 30 | 262 | 9 | 114 | 4-M16 | 114 | 4-M16 | 120.5 | 4-5/8" | 77 | F05 |

| BFL65-L-E | 65 | 275 | 245 | 77 | 44.7 | 49.1 | 30 | 262 | 9 | 127 | 4-M16 | 127 | 4-M16 | 139.5 | 4-5/8" | 77 | F05 |

| BFL80-L-E | 80 | 291 | 261 | 87 | 45.2 | 48.4 | 30 | 262 | 9 | 146 | 4-M16 | 146 | 4-M16 | 152.5 | 4-5/8" | 77 | F05 |

| BFL100-L-E | 100 | 335 | 305 | 112 | 52.1 | 55.3 | 30 | 262 | 11 | 178 | 4-M16 | 178 | 8-M16 | 190.5 | 8-5/8" | 90 | F07 |

| BFL125-L-E | 125 | 362 | 332 | 128 | 54.4 | 58.8 | 30 | 262 | 14 | 210 | 8-M16 | 210 | 8-M16 | 216 | 8-3/4" | 90 | F07 |

| BFL150-L-E | 150 | 391 | 361 | 143 | 55.8 | 59.1 | 30 | 262 | 14 | 235 | 8-M16 | 235 | 8-M20 | 241.5 | 8-3/4" | 90 | F07 |

| BFL200-L-E | 200 | 463 | 423 | 173 | 60.6 | 64.1 | 40 | 348 | 17 | 292 | 8-M16 | 292 | 8-M20 | 298.5 | 8-3/4" | 125 | F10 |

| BFL250-L-E | 250 | 539 | 499 | 210 | 65.6 | 71.8 | 40 | 510 | 22 | 356 | 8-M20 | 356 | 12-M20 | 362 | 12-7/8" | 125 | F10 |

| BFL300-L-E | 300 | 618 | 578 | 244 | 76.9 | 81 | 40 | 510 | 22 | 406 | 12-M20 | 406 | 12-M24 | 432 | 12-7/8" | 125 | F10 |

C dimension relates to body thickness & C1 relates to seat thickness.

All dimensions in mm unless shown otherwise.

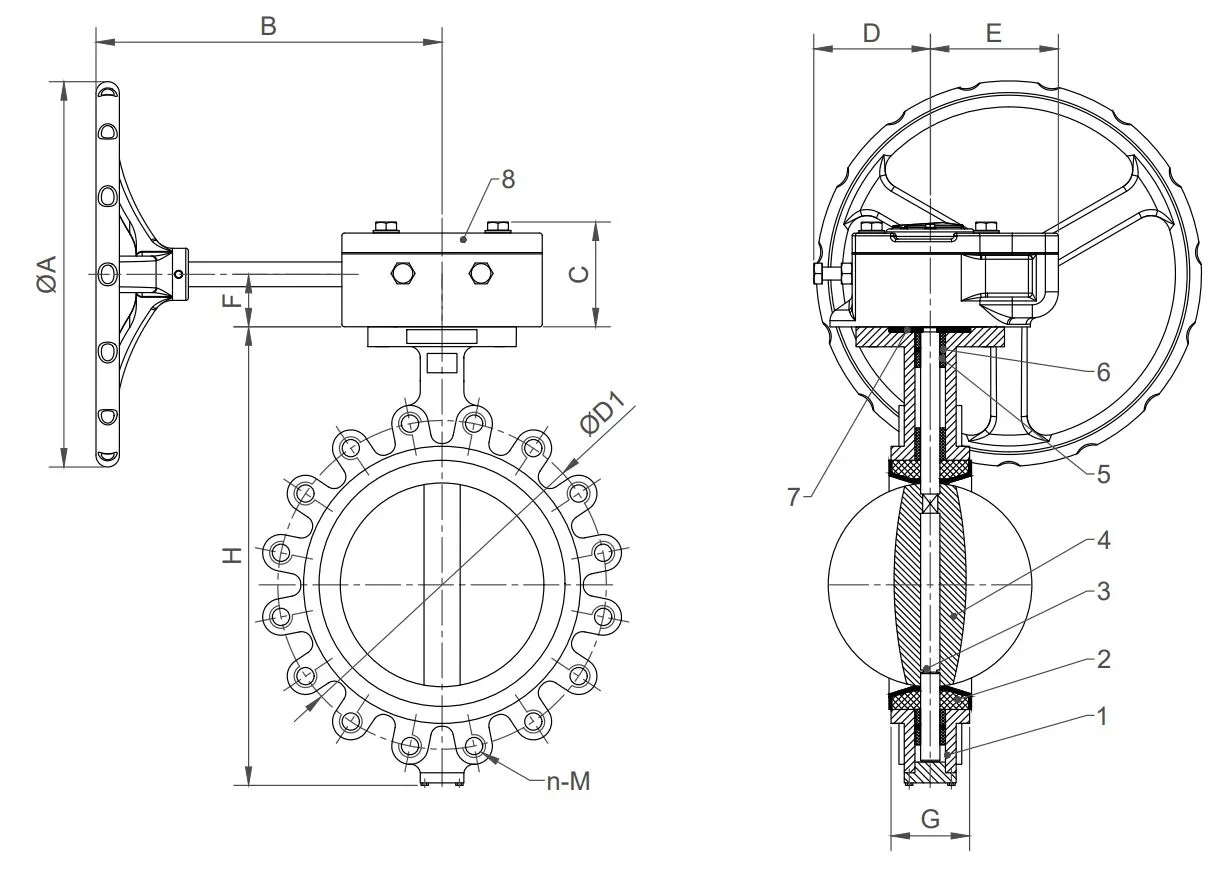

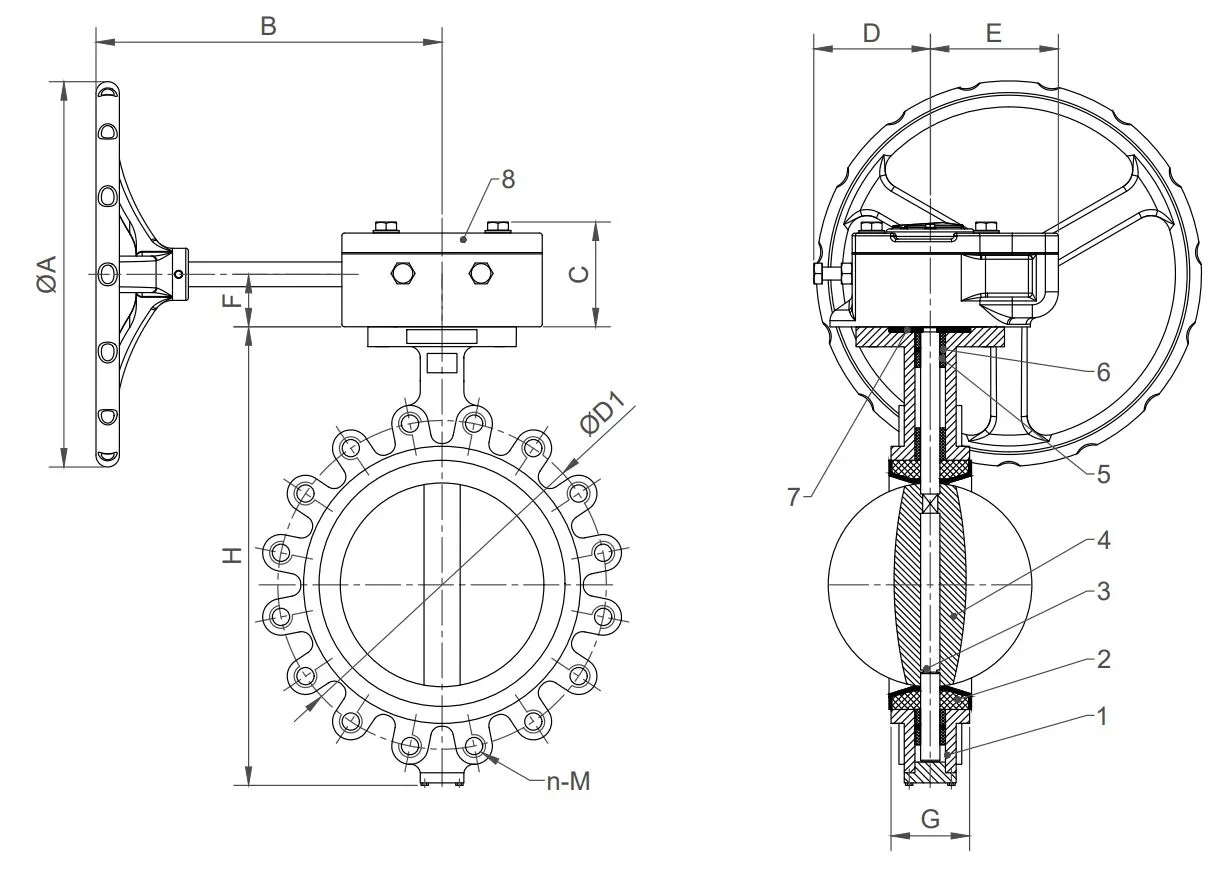

Sizes 350mm to 600mm

| Model | Size (DN) | Gearbox | ØA | B | C | D | E | F | G | H | L | AS2129 Table E | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | n-M | ||||||||||||

| BFL350-G-E | 350 | GB3 | 300 | 266 | 80.3 | 89.5 | 98.5 | 41 | 76.5 | 635 | 45 | 470 | 12-M24 |

| BFL400-G-E | 400 | GB4 | 350 | 330.5 | 110.7 | 107.5 | 120 | 49 | 86.5 | 709 | 51.2 | 521 | 12-M24 |

| BFL450-G-E | 450 | GB4 | 350 | 330.5 | 110.7 | 107.5 | 120 | 49 | 105.6 | 750 | 51.2 | 584 | 16-M24 |

| BFL500-G-E | 500 | GB4 | 350 | 330.5 | 110.7 | 107.5 | 120 | 49 | 131.8 | 841 | 64.2 | 641 | 16-M24 |

| BFL600-G-E | 600 | GB5 | 400 | 327.5 | 119.1 | 112.7 | 160 | 55 | 152 | 1021 | 70.2 | 756 | 16-M30 |

All dimensions in mm unless shown otherwise

Sizes 50mm to 300mm

| Item | Part | Material | Grade | Build & Test Standard |

|---|---|---|---|---|

| 1 | Body | Ductile Iron (FBE Coated) | AS1831500-7 | ASTM A536 |

| 2 | Seat | EPDM | 70 IRHD | - |

| 3 | Shaft | Stainless Steel | SS431 | ASTM A370 |

| 4 | Disc | Stainless Steel | CF8M | ASTM A370 |

| 5 | Bushing | Polymers | PTFE | - |

| 6 | O Ring | NBR | 70 IRHD | - |

| 7 | Handle | Ductile Iron (FBE Coated) | AS1831500-7 | ASTM A536 |

| 8 | Circlip | Stainless Steel | SS316 | ASTM A370 |

| 9 | Card | Stainless Steel | SS316 | ASTM A370 |

| 10 | Bolts & Nuts | Stainless Steel | A4-70 | - |

Sizes 350mm to 600mm

| Item | Part | Material | Grade | Build & Test Standard |

|---|---|---|---|---|

| 1 | Body | Ductile Iron (FBE Coated) | AS1831500-7 | ASTM A536 |

| 2 | Seat | EPDM | 70 IRHD | - |

| 3 | Shaft | Stainless Steel | SS431 | ASTM A370 |

| 4 | Disc | Stainless Steel | CF8M | ASTM A370 |

| 5 | Bushing | Polymers | PTFE | - |

| 6 | O Ring | NBR | 70 IRHD | - |

| 7 | Card | Stainless Steel | SS316 | ASTM A370 |

| 8 | Gearbox | Cast Iron |