Features:

Size 1/2" to 2" NPT

Body Forged Steel

Seat Metal

Pressure Range 0 to 136 BAR

Robust Class 800 A105 Forged Steel Gate Valve from 1/2" to 2" NPT with rising stem manual hand wheel. Suitable for pressures up to 136 Bar depending upon media temperature (See chart below) and type. Suitable for use across Petrochemical, Steam, Mining and Industrial applications Designed to API602 with NPT ends to ASME B1.20.1 and tested to API598.

| Model | Size (NPT) | Design Pressure | Media Temperature | Weight (kg) |

|---|---|---|---|---|

| GVF8-04 | 1/2" | 13.62 MPa @ -29°C ~ 35°C | 454°C @ 5.5 MPa | 2.22 |

| GVF8-05 | 3/4" | 2.39 | ||

| GVF8-06 | 1" | 4.24 | ||

| GVF8-07 | 1 1/4" | 5.7 | ||

| GVF8-08 | 1 1/2" | 7.05 | ||

| GVF8-09 | 2" | 10.9 |

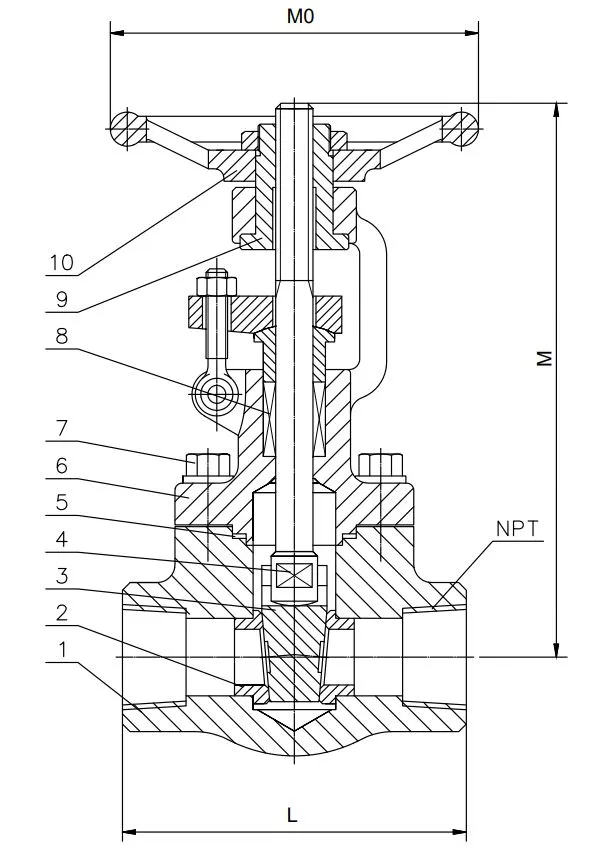

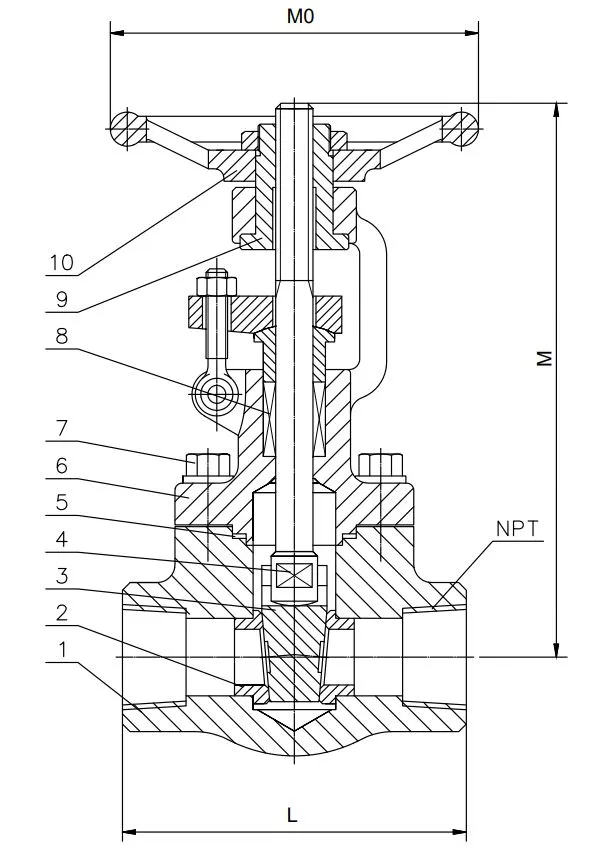

| Model | Size (NPT) | L | M | M0 |

|---|---|---|---|---|

| GVF8-04 | 1/2" | 79 | 155 | 100 |

| GVF8-05 | 3/4" | 92 | 155 | 100 |

| GVF8-06 | 1" | 111 | 176 | 125 |

| GVF8-07 | 1 1/4" | 120 | 200 | 160 |

| GVF8-08 | 1 1/2" | 120 | 220 | 160 |

| GVF8-09 | 2" | 140 | 255 | 180 |

All dimensions in mm unless shown otherwise.

| Number | Part Name | Material |

|---|---|---|

| 1 | Body | ASTM A105 |

| 2 | Seat | ASTM A276-420 |

| 3 | Wedge Disc | ASTM A276-420 |

| 4 | Stem | ASTM A276-410 |

| 5 | Gasket | Flexible Graphite/304 |

| 6 | Bonnet | ASTM A105 |

| 7 | Bonnet Bolt | ASTM A193 Gr.B7 |

| 8 | Packing | Flexible Graphite |

| 9 | Stem Nut | 1045 |

| 10 | Handwheel | ASTM A197 |

Size 1/2" to 2" NPT

Body Forged Steel

Seat Metal

Pressure Range 0 to 136 BAR

What is a Class 800 Forged Steel Gate Valve?

A Class 800 forged steel gate valve is a manual isolation valve designed to start or stop the flow of media in a pipeline using a gate (wedge) that moves up and down inside the valve body. The valve is constructed from robust forged steel, which delivers superior strength, pressure capability and resistance to impact compared with cast body designs. This particular model has NPT (National Pipe Thread) female threaded ends, meaning it is intended to screw directly onto matching male threaded pipework or fittings, making it a compact and reliable choice for high-pressure systems where welded or flanged connections aren’t needed.

How does a Class 800 Forged Steel Gate Valve work?

A gate valve operates by moving a disc-shaped gate perpendicular to the flow path. Turning the hand wheel rotates the stem which either lifts the gate out of the way to allow flow or lowers it down to block the flow. When fully open, the gate retracts into the body, creating a full bore straight-through flow path with minimal resistance or pressure drop. These valves are designed for on/off isolation and are not suitable for throttling or flow regulation, as partially opening the gate can cause vibration, turbulence and accelerated wear on the seating surfaces.

How long will my Class 800 Forged Steel Gate Valve last?

How long this valve will last depends on the application, media, operating conditions and how often it is cycled. The forged steel construction significantly increases strength and durability compared with cast valves, which makes Class 800 forged gate valves suitable for high-pressure and high-temperature environments, including steam, oil, gas and industrial fluid systems. When used within its design limits, a forged steel gate valve like this one can provide many years of reliable service. Regular operation (fully open/fully closed) and correct installation also help maximise valve performance and life.

How do I install a Class 800 Forged Steel Gate Valve?

Before installation, ensure the pipeline is fully depressurised and drained. This valve has female NPT threaded ends, so it must be installed onto matching male NPT threaded pipework or fittings. Apply a suitable thread sealant or PTFE tape on the male threads before threading the valve into place. Hand-tighten the valve first, then use a suitable wrench to complete the installation, keeping alignment straight to avoid stress on the pipework. Once installed, slowly bring the system up to pressure and inspect the threaded joints for any leaks. Properly sealed NPT threads create a strong mechanical and fluid-tight connection without the need for welding or flanges.

What are typical uses of a Class 800 Forged Steel Gate Valve?

Class 800 forged steel gate valves are commonly used in industrial and high-pressure applications due to their robust construction and elevated pressure capability (up to roughly 136 bar). They are suited for steam and thermal systems, oil & gas distribution, petrochemical processing, high-pressure water or chemical lines and any system where strong, compact threaded isolation is required. Their forged body and solid wedge design deliver excellent strength, tight seal performance and pressure endurance in demanding environments

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 1/2" to 2" NPT

Body Forged Steel

Seat Metal

Pressure Range 0 to 136 BAR

Robust Class 800 A105 Forged Steel Gate Valve from 1/2" to 2" NPT with rising stem manual hand wheel. Suitable for pressures up to 136 Bar depending upon media temperature (See chart below) and type. Suitable for use across Petrochemical, Steam, Mining and Industrial applications Designed to API602 with NPT ends to ASME B1.20.1 and tested to API598.

| Model | Size (NPT) | Design Pressure | Media Temperature | Weight (kg) |

|---|---|---|---|---|

| GVF8-04 | 1/2" | 13.62 MPa @ -29°C ~ 35°C | 454°C @ 5.5 MPa | 2.22 |

| GVF8-05 | 3/4" | 2.39 | ||

| GVF8-06 | 1" | 4.24 | ||

| GVF8-07 | 1 1/4" | 5.7 | ||

| GVF8-08 | 1 1/2" | 7.05 | ||

| GVF8-09 | 2" | 10.9 |

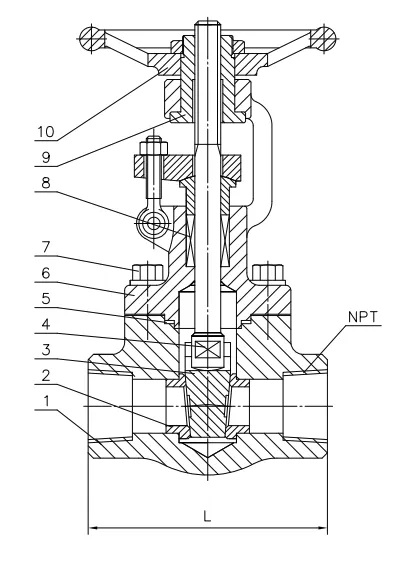

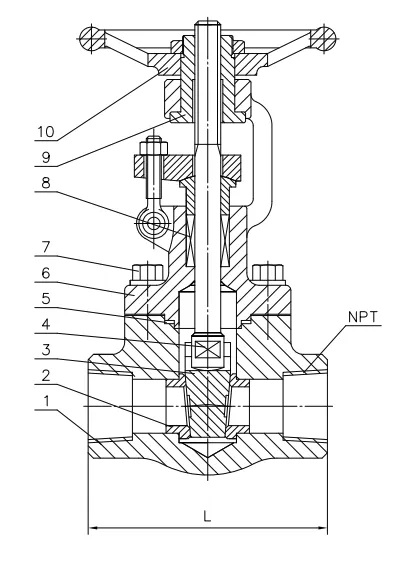

| Model | Size (NPT) | L | M | M0 |

|---|---|---|---|---|

| GVF8-04 | 1/2" | 79 | 155 | 100 |

| GVF8-05 | 3/4" | 92 | 155 | 100 |

| GVF8-06 | 1" | 111 | 176 | 125 |

| GVF8-07 | 1 1/4" | 120 | 200 | 160 |

| GVF8-08 | 1 1/2" | 120 | 220 | 160 |

| GVF8-09 | 2" | 140 | 255 | 180 |

All dimensions in mm unless shown otherwise.

| Number | Part Name | Material |

|---|---|---|

| 1 | Body | ASTM A105 |

| 2 | Seat | ASTM A276-420 |

| 3 | Wedge Disc | ASTM A276-420 |

| 4 | Stem | ASTM A276-410 |

| 5 | Gasket | Flexible Graphite/304 |

| 6 | Bonnet | ASTM A105 |

| 7 | Bonnet Bolt | ASTM A193 Gr.B7 |

| 8 | Packing | Flexible Graphite |

| 9 | Stem Nut | 1045 |

| 10 | Handwheel | ASTM A197 |