Features:

Size 1/2" to 2" NPT

Body Forged Steel

Seat PTFE

Pressure 130 BAR @ ambient

Actuation Lever

Robust A105 Forged Steel Class 800 Ball Valve with PTFE seats and a reduced bore. Suitable for use across Petrochemical, Steam, Mining and Industrial applications. Designed to ASME B16.34 with NPT ends to ASME B1.20.1 and tested to API 598. Please note: We carry the 1/2" & 2" in 3 pce body, all other sizes are 2 pce body as per the website image.

| Model | Size (NPT) | Design Pressure | Media Temperature | Weight (kg) | Torque (Nm) |

|---|---|---|---|---|---|

| BVF8-04 | 1/2" | 13.62 MPa @ -29°C ~ 35°C | 180°C @ 1.0 MPa | 1.3 | 15 |

| BVF8-05 | 3/4" | 2.2 | 18 | ||

| BVF8-06 | 1" | 3.5 | 27 | ||

| BVF8-07 | 1-1/4" | 6.5 | 45 | ||

| BVF8-08 | 1-1/2" | 6.7 | 65 | ||

| BVF8-09 | 2" | 11 | 90 |

Refer to Class 800 Pressure vs Temperature chart below for specific pressure and temperature information.

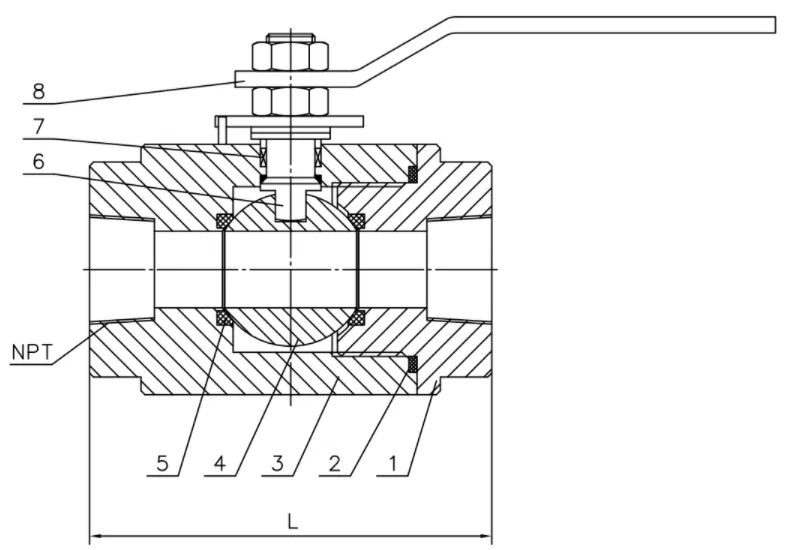

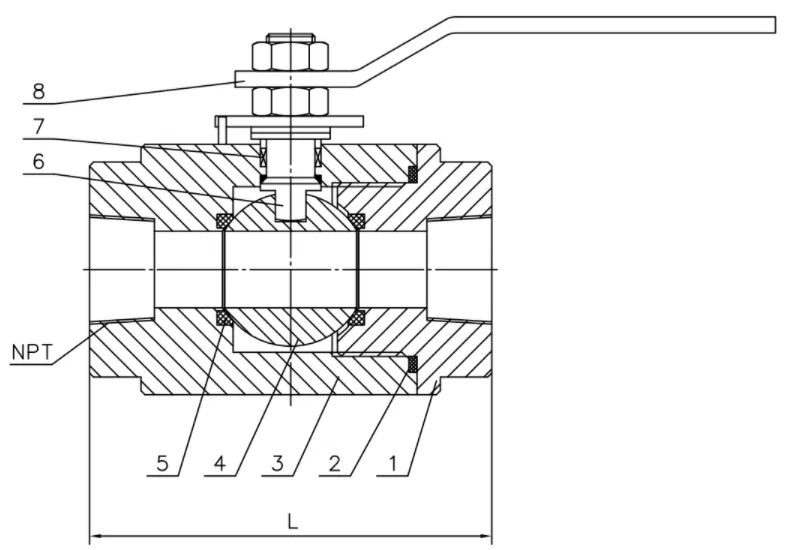

| Model | Size (NPT) | L |

|---|---|---|

| BVF8-04 | 1/2" | 85 |

| BVF8-05 | 3/4" | 95 |

| BVF8-06 | 1" | 105 |

| BVF8-07 | 1 1/4" | 120 |

| BVF8-08 | 1 1/2" | 130 |

| BVF8-09 | 2" | 150 |

All dimensions in mm unless shown otherwise.

| Number | Part Name | Material |

|---|---|---|

| 1 | Cap | ASTM A105 |

| 2 | Gasket | RPTFE |

| 3 | Body | ASTM A105 |

| 4 | Ball | ASTM A182-F304 |

| 5 | Seat | PTFE |

| 6 | Stem | ASTM A276-420 |

| 7 | Packing | RPTFE |

| 8 | Handle | SS+PVC |

Size 1/2" to 2" NPT

Body Forged Steel

Seat PTFE

Pressure 130 BAR @ ambient

Actuation Lever

What is a Forged Steel Class 800 Ball Valve?

A Class 800 Forged Steel Ball Valve is made of A105 Forged Steel Body that house the rotating ball inside it. These are two way units with a female port at either end. The Ball Valve is operated by rotating the Stainless Steel Handle 90 degrees which will open or close the ball valve. The handle is stopped at these positions by a limit stop on the body of the valve, this will stop the user moving the ball past the fully closed and fully open point.

How does a Forged Steel Class 800 Ball Valve Work?

Housed within the body of the ball valve is a polished 316 Stainless Steel Ball. This has a hole at either end which is equal to the inside diameter of the valve. When rotated 90 degrees it will either expose these holes to the flow or close them off from the flow allowing the valve to close or open. The ball is turned by a shaft which connects to a handle on the top of the valve. This type of Ball Valve is often called a floating ball valve as the ball itself is suspended within the cavity of the ball valve with the PTFE seats holding the ball from either end of the valve (and also sealing it).

What are Typical Uses of a Class 800 Forged Steel Ball Valve?

These Class 800 Forged Steel Ball Valves are commonly used as an isolation valve in applications which require a class 800 specification. Really they can be used in any application where the media, temperature and pressure fit within the scope of the ball valve.

How do I install a Forged Steel Class 800 Ball Valve?

These are very easy to install as they are bi-directional meaning they do not have a direction of flow (unlike a solenoid valve for instance). This model has female threaded ends so a male nipple or thread will need to be inserted into the valve. Ensure that this has appropriate thread sealant or tape to achieve a bubble tight seal. They can be installed on any axis and any way if needed. Before installation the line must be isolated and pressure removed. Once the installation is complete the line can be brought back to pressure and the ball valve checked for proper usage.

How long will my Forged Steel Class 800 Ball Valve Last?

This really depends upon the environment and media that the ball valve is exposed to. The cycle rate will feature heavily as well as if the valve is only cycled once a day it may well last over a decade however if it is cycled frequently it will wear out sooner.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 1/2" to 2" NPT

Body Forged Steel

Seat PTFE

Pressure 130 BAR @ ambient

Actuation Lever

Robust A105 Forged Steel Class 800 Ball Valve with PTFE seats and a reduced bore. Suitable for use across Petrochemical, Steam, Mining and Industrial applications. Designed to ASME B16.34 with NPT ends to ASME B1.20.1 and tested to API 598. Please note: We carry the 1/2" & 2" in 3 pce body, all other sizes are 2 pce body as per the website image.

| Model | Size (NPT) | Design Pressure | Media Temperature | Weight (kg) | Torque (Nm) |

|---|---|---|---|---|---|

| BVF8-04 | 1/2" | 13.62 MPa @ -29°C ~ 35°C | 180°C @ 1.0 MPa | 1.3 | 15 |

| BVF8-05 | 3/4" | 2.2 | 18 | ||

| BVF8-06 | 1" | 3.5 | 27 | ||

| BVF8-07 | 1-1/4" | 6.5 | 45 | ||

| BVF8-08 | 1-1/2" | 6.7 | 65 | ||

| BVF8-09 | 2" | 11 | 90 |

Refer to Class 800 Pressure vs Temperature chart below for specific pressure and temperature information.

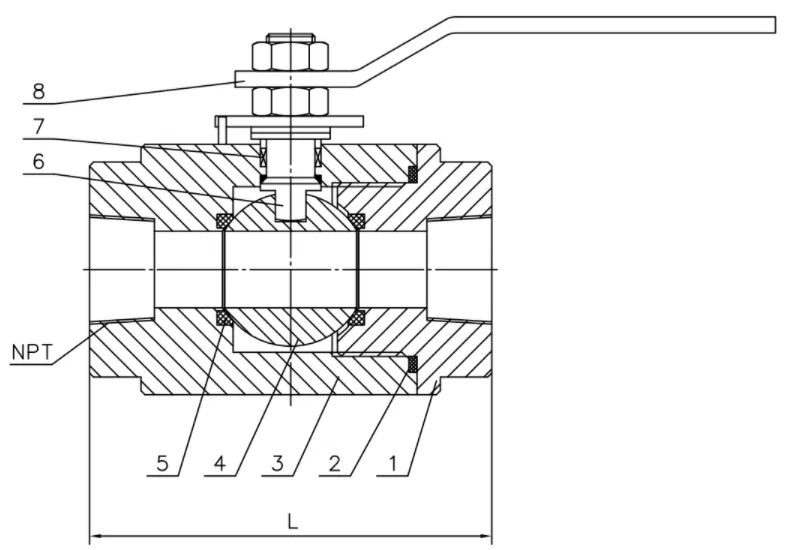

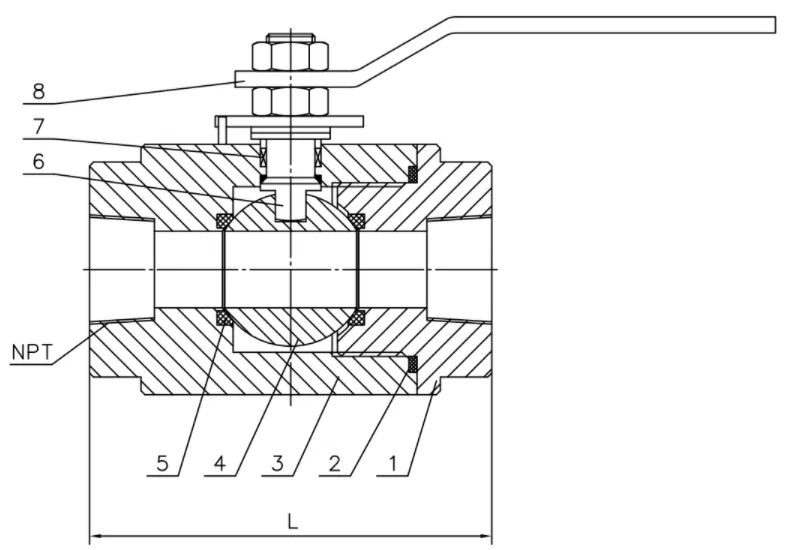

| Model | Size (NPT) | L |

|---|---|---|

| BVF8-04 | 1/2" | 85 |

| BVF8-05 | 3/4" | 95 |

| BVF8-06 | 1" | 105 |

| BVF8-07 | 1 1/4" | 120 |

| BVF8-08 | 1 1/2" | 130 |

| BVF8-09 | 2" | 150 |

All dimensions in mm unless shown otherwise.

| Number | Part Name | Material |

|---|---|---|

| 1 | Cap | ASTM A105 |

| 2 | Gasket | RPTFE |

| 3 | Body | ASTM A105 |

| 4 | Ball | ASTM A182-F304 |

| 5 | Seat | PTFE |

| 6 | Stem | ASTM A276-420 |

| 7 | Packing | RPTFE |

| 8 | Handle | SS+PVC |