Features:

Size 1/2" to 4" BSP

Body 316 Stainless Steel 3 piece 60 degree V port

Seat Reinforced PTFE

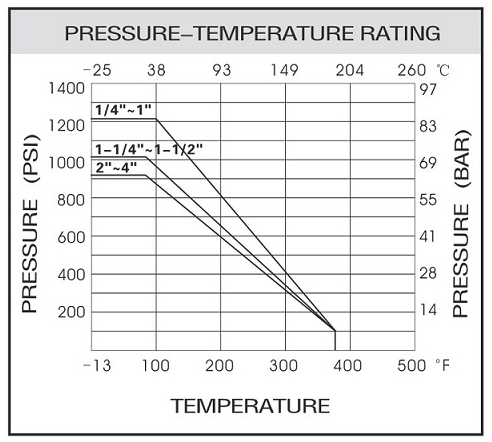

Pressure 63 BAR

Temperature -20°C to 180°C

Actuation Lockable Lever

Watermark Approved

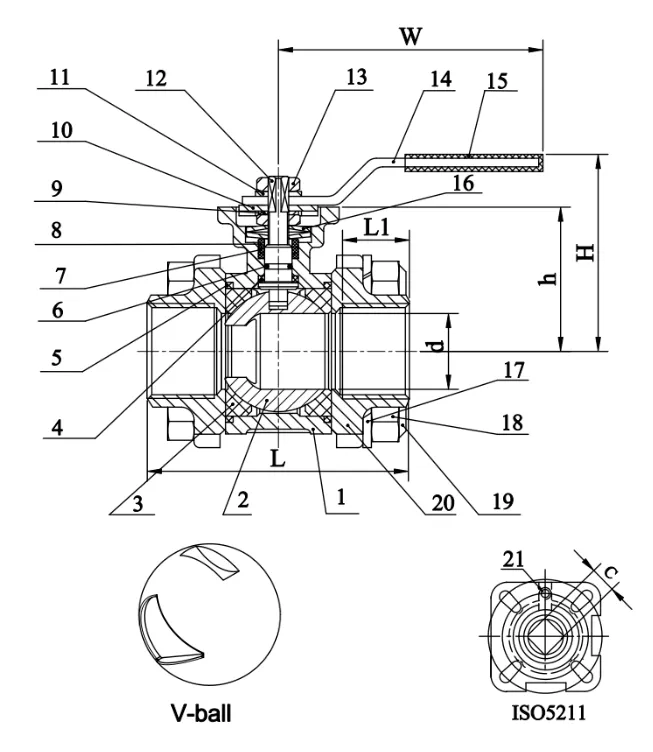

High performance 3 piece full bore 316 Stainless Steel 60 degree V port ball valve with BSP threaded connections. Self adjusting stem packing assembly with belleville spring for temperature fluctuations and vibration. Pre drilled metric hole on ISO5211 direct mounting pad to minimise any thermal transfer from valve to actuator. Reinforced PTFE seats for temperatures up to 180°C. Typically used in situations where a finer degree of flow control is needed. Comes with lockable handle. Can be direct mounted with a modulating electric actuator or a spring return or double acting pneumatic actuator with a electro-pneumatic positioner to give positioning. Can upgrade to 50/50 stainless steel seats for higher temperature/higher wear applications. Threads conform to ISO 7.1 Sealing Threads.

| Model | Size (BSP) | Oriffice (mm) | Media Pressure | Media Temperature | Torque (Nm) |

|---|---|---|---|---|---|

| BLV4B-L-T60 | 1/2 | 15 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 7 |

| BLV5B-L-T60 | 3/4 | 20 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 11 |

| BLV6B-L-T60 | 1 | 25 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 13 |

| BLV7B-L-T60 | 1 ¼ | 32 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 18 |

| BLV8B-L-T60 | 1 ½ | 40 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 23 |

| BLV9B-L-T60 | 2 | 50 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 32 |

| BLV10B-L-T60 | 2 ½ | 65 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 65 |

| BLV11B-L-T60 | 3 | 80 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 100 |

| BLV12B-L-T60 | 4 | 100 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 145 |

Available with double acting pneumatic, spring return pneumatic and electric actuation. For flow rate information, please see our references page here.

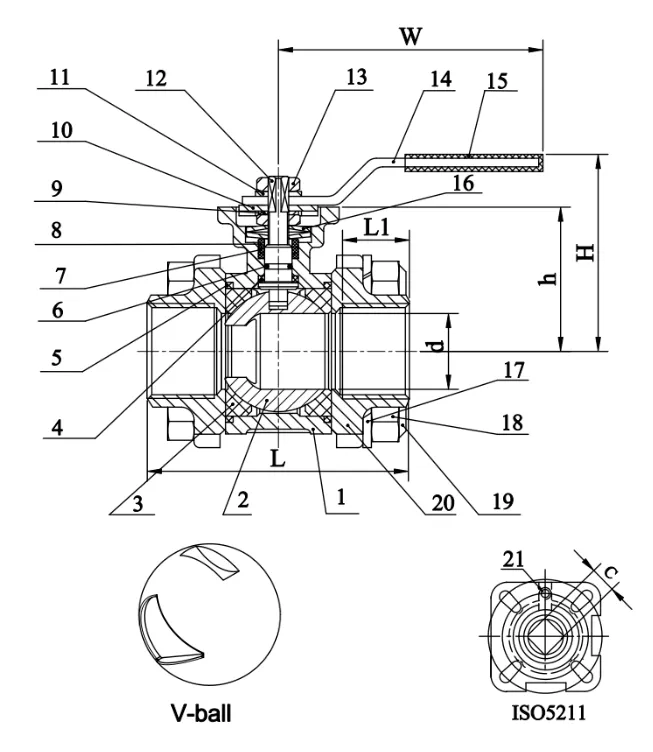

| Size | d | L | L1 | H | h | C | W | ISO5211 | Kg |

|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 15 | 75 | 15.5 | 70 | 42 | 9 | 117 | F03/F04 | 0.5 |

| 3/4" | 20 | 80 | 16 | 78 | 50 | 11 | 134 | F04/F05 | 0.89 |

| 1" | 25 | 90 | 19 | 87 | 58 | 11 | 134 | F04/F05 | 1.28 |

| 1-1/4" | 32 | 110 | 21 | 98 | 64 | 14 | 203 | F05/F07 | 1.99 |

| 1-1/2" | 40 | 120 | 21 | 104 | 69.5 | 14 | 203 | F05/F07 | 2.96 |

| 2" | 50 | 140 | 25 | 112 | 78 | 14 | 203 | F05/F07 | 3.75 |

| 2-1/2" | 65 | 185 | 30 | 140 | 100 | 17 | 255 | F07/F10 | 7.8 |

| 3" | 80 | 205 | 33 | 153 | 112.5 | 17 | 255 | F07/F10 | 12.4 |

| 4" | 100 | 240 | 39 | 166 | 125.5 | 17 | 302 | F07/F10 | 20.8 |

All dimensions in mm unless shown otherwise.

| Item | Part | Material | Qty |

|---|---|---|---|

| 1 | Body | CF8M | 1 |

| 2 | Ball | SS316 | 1 |

| 3 | Ball Seat | 15%RPTFE | 2 |

| 4 | Thrust Washer | PTFE | 1 |

| 5 | Body Gasket | PTFE | 2 |

| 6 | O-Ring | Viton | 1 |

| 7 | Stem Packing | PTFE | 1 |

| 8 | Gland | SS304 | 1 |

| 9 | Tab Washer | SS304 | 1 |

| 10 | Stopper | SS304 | 1 |

| 11 | Spring Washer | SS304 | 1 |

| Item | Part | Material | Qty |

|---|---|---|---|

| 12 | Stem | SS316 | 1 |

| 13 | Nut | SS304 | 2 |

| 14 | Handle | SS304 | 1 |

| 15 | Handle Cover | Plastic | 1 |

| 16 | Belleville Washer | SS301 | 2 |

| 17 | Spring Washer | SS304 | 4 |

| 18 | Nut | SS304 | 4 |

| 19 | Bolt | SS304 | 4 |

| 20 | Cap | CF8M (1.4408) | 2 |

| 21 | Stop Pin | SS304 | 1 |

Size 1/2" to 4" BSP

Body 316 Stainless Steel 3 piece 60 degree V port

Seat Reinforced PTFE

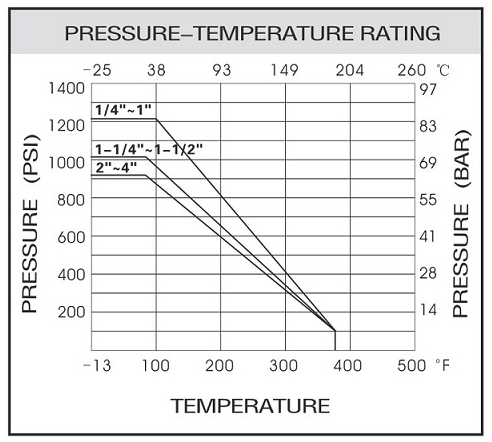

Pressure 63 BAR

Temperature -20°C to 180°C

Actuation Lockable Lever

Watermark Approved

What is a 2 Way V port Stainless Steel Ball Valve?

A three piece two way stainless steel V port ball valve is constructed of three seperate body pieces and held together by the use of stainless steel tie rods with nuts at either end. This kind of design makes it easy to remove the valve from a line as you do not need to unscrew the ends from the pipework to maintain the valve. It is also very easy to change the valve seats as you can access them directly when the ends are removed making them ideal for applications where the seat is worn regularly. Our design also has a longer neck to reduce thermal transfer and a direct mounting pad for mounting actuators without the use of a bracket and drive dog. They also have a reinforced teflon (PTFE) seat which is filled with a 15% glass filler. This allows higher pressures and temperatures up to 180 degrees celcius making it suitable for steam applications (refer to the temperature vs pressure graph). If a higher temperature is required these seats can be changed out to a 50% stainless steel seat if required. The ball itself has a 60 degree V port in it so it will not achieve a full flow like a typical full bore ball valve but it will allow a higher degree of flow control.

How does a 3 Piece Two Way Stainless Steel V port Ball Valve work?

These V port ball valves work the same as any normal two way ball valve whereby the ball is rotated 90 degrees within the body of the valve which will either open or close the valve. The ball itself has a V port in it which the media will flow through when it is open. When the valve is closed these holes are blocked off to the flow effectively isolating the media either side of the valve. The ball is turned by a handle (or actuator) which is connected to a shaft which in turn is mated to the ball by a female slot. When it is operated by a handle (our handles are lockable) there is a stop pin which only allows you to operate the valve in a 90 degree turn (this will take you from open to close or vice versa). When it is operated by a gear box the gear box will hit its stop on the worm drive which will not let the ball rotate past 90 degrees.

How long will my V port Stainless Steel Ball Valve last?

Like any valve this depends upon the usage case of your ball valve, its environment, media and how many times it is cycled. For instance if it is on a clean media, in a clean environment and not cycled regularly the life will be decades. As it is a V port and mostly used for flow control quite often the ball is only partly open. This exposes the seat to the media more than a traditional ball valve so will wear at a higher rate. Being a 3 piece construction it is relatively easy to change the seats out when there wear which is the main perishable in the valve. These are available as spare parts in a repair kit.

How do I install a V port Stainless Steel Ball Valve?

These have female paralell BSP threaded ends so it is best to put a male tapered BSP fitting into the valve ends. Thread tape or a sealant should be used to help the seal and also if dissimilar metals are used it will reduce dissimilar metal corrosion. The tie rods can be undone if needed and the ends installed by themselves but this is usually unnecessary and you would have to measure the exact face to face before your installation.

What are typical uses of a V port Stainless Steel ball valve?

These V port ball valves are usually only used where a degree of flow control is desired. Examples include flow regulation in steam systems, water systems and any other application where the media, temperature and pressure is compatible.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 1/2" to 4" BSP

Body 316 Stainless Steel 3 piece 60 degree V port

Seat Reinforced PTFE

Pressure 63 BAR

Temperature -20°C to 180°C

Actuation Lockable Lever

Watermark Approved

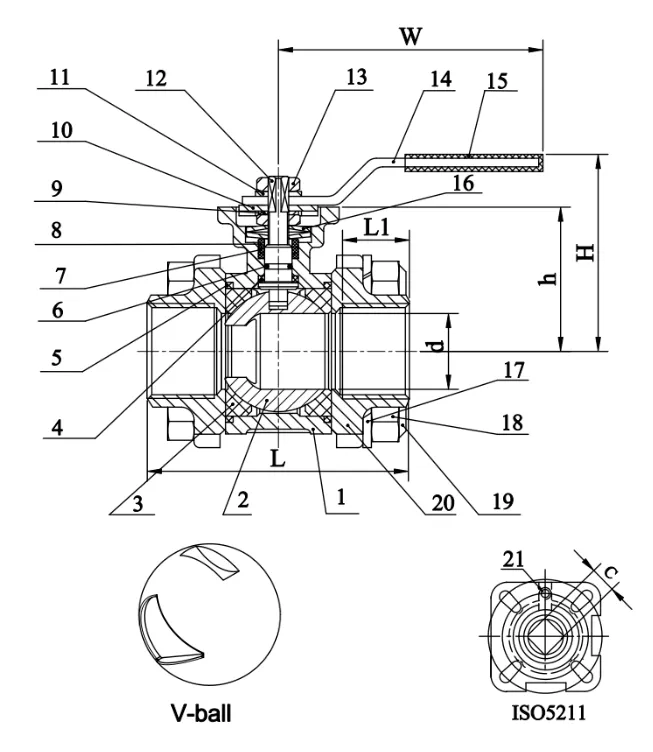

High performance 3 piece full bore 316 Stainless Steel 60 degree V port ball valve with BSP threaded connections. Self adjusting stem packing assembly with belleville spring for temperature fluctuations and vibration. Pre drilled metric hole on ISO5211 direct mounting pad to minimise any thermal transfer from valve to actuator. Reinforced PTFE seats for temperatures up to 180°C. Typically used in situations where a finer degree of flow control is needed. Comes with lockable handle. Can be direct mounted with a modulating electric actuator or a spring return or double acting pneumatic actuator with a electro-pneumatic positioner to give positioning. Can upgrade to 50/50 stainless steel seats for higher temperature/higher wear applications. Threads conform to ISO 7.1 Sealing Threads.

| Model | Size (BSP) | Oriffice (mm) | Media Pressure | Media Temperature | Torque (Nm) |

|---|---|---|---|---|---|

| BLV4B-L-T60 | 1/2 | 15 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 7 |

| BLV5B-L-T60 | 3/4 | 20 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 11 |

| BLV6B-L-T60 | 1 | 25 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 13 |

| BLV7B-L-T60 | 1 ¼ | 32 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 18 |

| BLV8B-L-T60 | 1 ½ | 40 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 23 |

| BLV9B-L-T60 | 2 | 50 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 32 |

| BLV10B-L-T60 | 2 ½ | 65 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 65 |

| BLV11B-L-T60 | 3 | 80 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 100 |

| BLV12B-L-T60 | 4 | 100 | Vacuum (29" Hg) to 63 Bar | -20°C to 180°C | 145 |

Available with double acting pneumatic, spring return pneumatic and electric actuation. For flow rate information, please see our references page here.

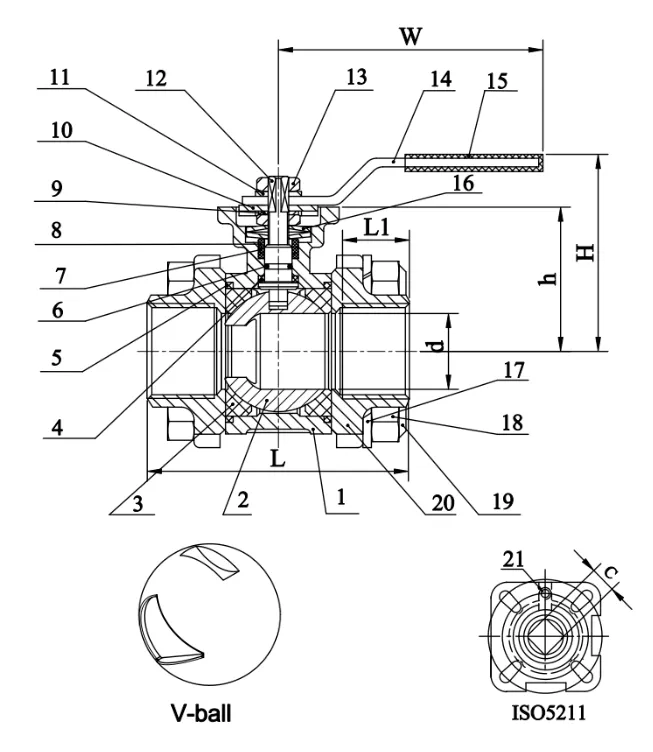

| Size | d | L | L1 | H | h | C | W | ISO5211 | Kg |

|---|---|---|---|---|---|---|---|---|---|

| 1/2" | 15 | 75 | 15.5 | 70 | 42 | 9 | 117 | F03/F04 | 0.5 |

| 3/4" | 20 | 80 | 16 | 78 | 50 | 11 | 134 | F04/F05 | 0.89 |

| 1" | 25 | 90 | 19 | 87 | 58 | 11 | 134 | F04/F05 | 1.28 |

| 1-1/4" | 32 | 110 | 21 | 98 | 64 | 14 | 203 | F05/F07 | 1.99 |

| 1-1/2" | 40 | 120 | 21 | 104 | 69.5 | 14 | 203 | F05/F07 | 2.96 |

| 2" | 50 | 140 | 25 | 112 | 78 | 14 | 203 | F05/F07 | 3.75 |

| 2-1/2" | 65 | 185 | 30 | 140 | 100 | 17 | 255 | F07/F10 | 7.8 |

| 3" | 80 | 205 | 33 | 153 | 112.5 | 17 | 255 | F07/F10 | 12.4 |

| 4" | 100 | 240 | 39 | 166 | 125.5 | 17 | 302 | F07/F10 | 20.8 |

All dimensions in mm unless shown otherwise.

| Item | Part | Material | Qty |

|---|---|---|---|

| 1 | Body | CF8M | 1 |

| 2 | Ball | SS316 | 1 |

| 3 | Ball Seat | 15%RPTFE | 2 |

| 4 | Thrust Washer | PTFE | 1 |

| 5 | Body Gasket | PTFE | 2 |

| 6 | O-Ring | Viton | 1 |

| 7 | Stem Packing | PTFE | 1 |

| 8 | Gland | SS304 | 1 |

| 9 | Tab Washer | SS304 | 1 |

| 10 | Stopper | SS304 | 1 |

| 11 | Spring Washer | SS304 | 1 |

| Item | Part | Material | Qty |

|---|---|---|---|

| 12 | Stem | SS316 | 1 |

| 13 | Nut | SS304 | 2 |

| 14 | Handle | SS304 | 1 |

| 15 | Handle Cover | Plastic | 1 |

| 16 | Belleville Washer | SS301 | 2 |

| 17 | Spring Washer | SS304 | 4 |

| 18 | Nut | SS304 | 4 |

| 19 | Bolt | SS304 | 4 |

| 20 | Cap | CF8M (1.4408) | 2 |

| 21 | Stop Pin | SS304 | 1 |