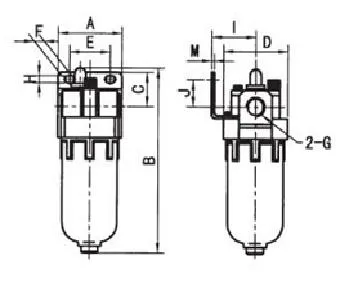

Features:

Size 1/4" to 2" BSP

Function Lubricator

Body Die Cast Aluminium

Pressure Range 0 to 8 BAR

Media Air

These lubricators work by emitting a micro fog into the air stream which preserves, prolongs and enhances the performance of down stream machinery. The amount of lubrication emitted is adjustable and all models include mounting bracket (except 1 1/2" & 2"). Easy to install, maintain and refill. Comes with polycarbonate bowl guard with sight glass.

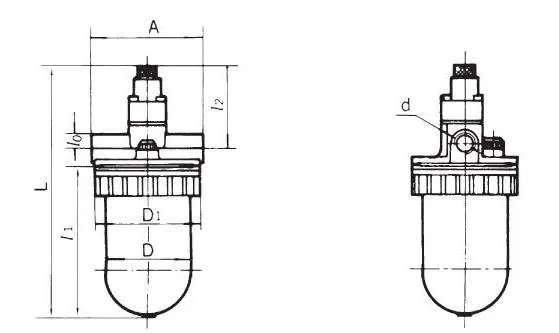

Size 1/4" to 2" BSP

Function Lubricator

Body Die Cast Aluminium

Pressure Range 0 to 8 BAR

Media Air

What is an Air Lubricator?

A Lubricator is used in compressed air systems to deliver lubricated air to pneumatic control valves, actuators, pneumatic tools, and HVAC systems (and other downstream products). The Air Lubricator function is to increase performance and reduce maintenance by delivering controlled lubrication to the internal moving parts of machinery operating on compressed air. Air lubricators come in two types - oil fog and micro fog. Standard units are micro fog as this gives the best atomised mist. Oil fog units are only used on machine slides where large amounts of lubrication are required.

How does a Compressed Air Lubricator work?

Air enters the lubricator and flows through to the outlet port. An internal venturi tube picks up the oil and dips it back into the bowl vai a visual sight dome. The micro mist created in the bowl is picked up and mixed in with the air supply. However only a small percentage of the mist actually goes downstream as it is in turn controlled by an orifice. The result is a very small amount of oil continuously mixed in with the air supply. The bowl is polycarbonate with a guard allowing visual inspection of the oil level.

How do I size a Lubricator?

The units are sized according to their port sizes (¼” - 1” Bsp). The usual method is to match the port size of the pipe that is feeding the equipment i.e. ½” tube supply will be a ½” Bsp lubricator. The other method is to work out the required flow rate for the equipment to be serviced with the rating of the lubricator plus a 30% safety factor. Pressure range is 0.5 to 8.5 Bar and working temperature to 60 degrees celsius.

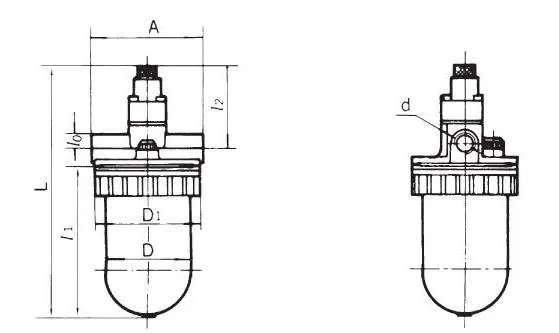

How long will my Compressed Air Lubricator Last?

By providing a pre-filter to control any upstream pipe scale or contamination you will ensure the best operating environment for your Lubricator. Regular maintenance should be scheduled to fill the oil. However this frequency will be subject to individual applications. With no moving parts and scheduled maintenance these units will last decades.

How do I install an Air Oiler?

The unit is mounted horizontally in the direction of flow (as marked on the body). The oil bowl must be vertical to operate. A light mineral oil that is manufactured for this application is used in the oiler. Mounting brackets hold the assembly at either end and can be mounted onto any convenient structure.

What are typical uses of a Compressed Air Lubricator?

The oiler is used in compressed air systems to deliver lubricated air to downstream equipment. This extends the life of the internal moving parts. Check that oil lubrication is required in the machinery before installing as a lot of modern items (for example our pneumatic actuators) are pre lubricated and do not require extra lubrication in the line.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all Lubricators leave our warehouse tested and inspected so there are rarely any issues. Also once your Lubricator is in and operating wiht appropriate filtartion upstream, it will most likely continue to do so for a very long time barring any external factors.

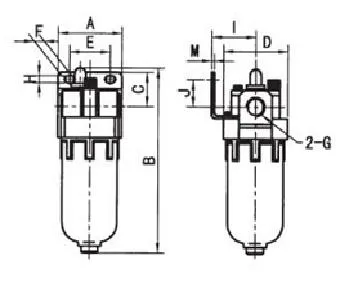

Size 1/4" to 2" BSP

Function Lubricator

Body Die Cast Aluminium

Pressure Range 0 to 8 BAR

Media Air

These lubricators work by emitting a micro fog into the air stream which preserves, prolongs and enhances the performance of down stream machinery. The amount of lubrication emitted is adjustable and all models include mounting bracket (except 1 1/2" & 2"). Easy to install, maintain and refill. Comes with polycarbonate bowl guard with sight glass.