Features:

Size 1/4" to 1" BSP

Function Filter, Regulator & Lubricator combo unit

Body Die Cast Aluminium

Pressure Range 0.5 to 8.5 BAR

Media Air

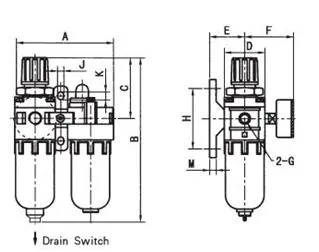

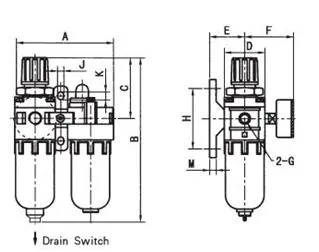

Modular style of air preparation equipment which includes a Filter Regulator and a Lubricator joined together by a mounting bracket. This cleans the air of water, oil and other suspended debris, regulates the downstream pressure and injects mico mist lubricant into the cleaned air to give air tools and machines longer life. Easy to install and service, all units come with mounting bracket, guage, auto drain and polycarbonate bowl guard with sight glass.

Size 1/4" to 1" BSP

Function Filter, Regulator & Lubricator combo unit

Body Die Cast Aluminium

Pressure Range 0.5 to 8.5 BAR

Media Air

What is a Filter, Regulator and Lubricator?

A Filter/Regulator and Lubricator combination unit is used in compressed air systems to deliver clean, regulated and lubricated air to pneumatic control valves, actuators, pneumatic tools, and HVAC systems (and other downstream products). The Air Service Units function is to increase performance and reduce maintenance from pipe scale, water condensate and burnt compressor oil. Commonly known as an FRL the units are sold as an assembly with mounting brackets and gauge.

How does a Filter Regulator Lubricator work?

Air enters the filter and is spun around in the bowl with vanes mounted in the air flow causing a centrifugal action. Water and condensate collects at the bottom of the bowl where it is drained away via an automatic or manual float assembly. The filter bowl is polycarbonate with a guard allowing visual inspection of the condensate. The air continues up through a filter element (usually 5 micron) which removes dirt particles from the air flow. Incorporated above the filter the adjustable regulator sets the required system pressure as shown by the external gauge. The air then moves to the oiler where a light atomised mineral oil is added into the flow continuing out to the pneumatic system.

How do I size a FRL?

The units are sized according to their port sizes (¼” - 1” Bsp). The usual method is to match the port size of the pipe that is feeding the equipment i.e. ½” tube supply will be a ½” Bsp FRL. The other method is to work out the required flow rate for the equipment to be serviced with the rating of the FRL plus a 30% safety factor. Pressure range is 0.5-8.5 Bar and working temperature to 60 deg.C

How long will my FRL Last?

Cleaning of the filter element is dependent upon the amount of contamination in the air supply. Regular maintenance should be scheduled to clean the filter and fill the oil. However this frequency will be subject to individual applications. With few moving parts and scheduled maintenance these units will last decades.

How do I install a Filter Regulator Lubricator?

The unit is mounted horizontally in the direction of flow (as marked on the body). The filter bowl and oiler bowl must be vertical to operate. Mounting brackets hold the assembly at either end and can be mounted onto any convenient structure.

What are typical uses of a FRL?

The air service unit is used in compressed air systems to deliver clean air, regulated and lubricated to give pneumatic control valves, actuators, pneumatic tools, and HVAC systems. They protect valuable instruments and tools from internal damage due to contamination in the air ring main.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all FRL's leave our warehouse tested and inspected so there are rarely any issues. Also once your FRL is in and operating it will most likely continue to do so for a very long time barring any external factors.

Size 1/4" to 1" BSP

Function Filter, Regulator & Lubricator combo unit

Body Die Cast Aluminium

Pressure Range 0.5 to 8.5 BAR

Media Air

Modular style of air preparation equipment which includes a Filter Regulator and a Lubricator joined together by a mounting bracket. This cleans the air of water, oil and other suspended debris, regulates the downstream pressure and injects mico mist lubricant into the cleaned air to give air tools and machines longer life. Easy to install and service, all units come with mounting bracket, guage, auto drain and polycarbonate bowl guard with sight glass.