Features:

Size 1/2" to 1" BSPT

Body 316 Stainless Steel

Pressure Range 0.1 to 20 BAR

Temperature -10°C to 180°C

316 Stainless Steel Air Vent with stainless internals and FKM seals & seat. Includes integral stainless strainer & adjustable flow control outlet. The thread of the vent is M6 and diameter of the vent hole is 1mm on all units.

| Model | Size | Media Pressure | Media Temperature |

|---|---|---|---|

| AVS-04 | 1/2" | 0.1 to 20 Bar | -10°C to 180°C |

| AVS-05 | 3/4" | 0.1 to 20 Bar | -10°C to 180°C |

| AVS-06 | 1" | 0.1 to 20 Bar | -10°C to 180°C |

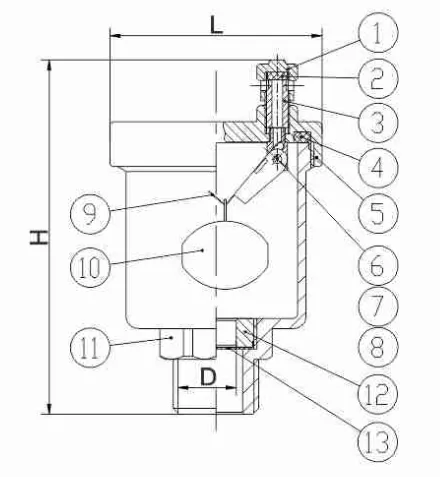

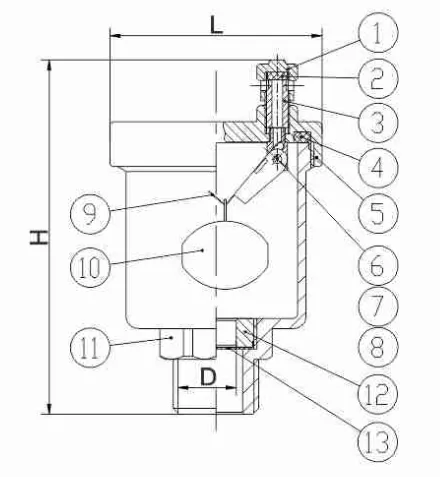

| Model | Size | L | H | D |

|---|---|---|---|---|

| AVS-04 | 1/2" | 52 | 88 | 10 |

| AVS-05 | 3/4" | 52 | 91 | 15 |

| AVS-06 | 1" | 52 | 93 | 22 |

All dimensions are in mm unless specified otherwise

| Item No. | Description | Material |

|---|---|---|

| 1 | Cap | SS304 |

| 2 | Gasket | FKM |

| 3 | Exhaust Column | SS304 |

| 4 | O-Ring | FKM |

| 5 | Bonnet | SS316 |

| 6 | Sealing Column | SS316 |

| 7 | Balancing Column | SS316 |

| Item No. | Description | Material |

|---|---|---|

| 8 | Gasket | FKM |

| 9 | Bouncing Slince | SS316 |

| 10 | Float | SS316 |

| 11 | Valve Body | SS316 |

| 12 | Lock Nut | SS304 |

| 13 | Strainer | SS304 |

Size 1/2" to 1" BSPT

Body 316 Stainless Steel

Pressure Range 0.1 to 20 BAR

Temperature -10°C to 180°C

What is an Air Vent Valve?

An Air Vent or Air Eliminator valve is a mechanical device that discharges air from liquid systems such as cold or hot water in order to avoid air related problems in fluid piping systems.

How does an Air Vent work?

They are designed to improve the circulation of pressurised liquids by eliminating air and other non-condensable gases which may collect at high points in the system. When first commissioned, the float is in the lowered position and the attached valve is off the seat; the valve is in the wide open position allowing air and other gases to flow freely to the atmosphere. When water/liquid enters into the valve any air/gas is exhausted out of the valve seat being pushed out by the incoming liquid. Once all the gas is expelled and liquid floods the valve, the float becomes buoyant and floats up to close off the valve. With further air or gas entering the valve body the cycle starts over and the float drops immediately opening the valve and exhausting the air. On start-up significant amounts of air may be in the system. Once the bulk of the startup air is expelled the air vent will continue to cycle, automatically releasing the gas as required. They usually come in sizes 15 to 32mm and are usually screwed type connections.

How long will my Air Vent Valve last?

This really depends upon the environment and the quality of the media that the Air vent operates within. With regular checks for correct operation an Automatic Air Vent should perform for many years. Obviously, it must be installed in accordance with the manufacturer's recommendations, maximum operating pressures must be adhered to. If during a check it is found to be faulty it should be cleaned, repaired as required. This will give the Air Vent the best opportunity to continually operate satisfactorily for many years. Various models will have varying materials of construction and limitations on operational pressure, temperature and capacity. It is important that each air vent is selected to suit the environment and required operating conditions. The discharge amount depends on the size and model. Please refer to the manufacturers sizing and selection chart to select a model adequate/suitable for the required duty.

How do I install an Air Vent?

Always follow the manufacturer's recommendations for installation. Due to the design of the float and valve system they must be in the vertical position above the piping with the inlet at the bottom. Inlet piping should never be smaller than the inlet connection and a full bore isolating valve should be used to eliminate any restrictions. The best place is where air tends to collect in your system and at the high points in any system as air will be pushed to these locations. More than one Air Vent may be required in any given installation. It is recommended to install a full bore isolating valve prior to the air vents for ease of maintenance. If the valve becomes contaminated it may dribble, it is recommended to run any discharge pipework to drain usually over an open tundish.

What are typical uses of an Air Vent Valve?

They are used most commonly, for protecting piping ancillaries from corrosion due to air (oxygen). Also air in a typical water service can also cause spitting out outlet points and noise as a result of air trapped in cold/hot water supply systems, air conditioning systems, and other liquid systems. Air in pumped systems can cause cavitational issues with the circulating pumps. Collecting air and removing it from a fluid system will offer quieter, smooth startups and stable operation. They can typically be used on cold & hot water and also oils with suitable specific gravity, Pump suction lines, Condensate return Lines, Storage tanks, cooling water lines etc. Always ask your supplier for the recommended air vent for the fluid being vented.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested and inspected so there are rarely any issues.

Size 1/2" to 1" BSPT

Body 316 Stainless Steel

Pressure Range 0.1 to 20 BAR

Temperature -10°C to 180°C

316 Stainless Steel Air Vent with stainless internals and FKM seals & seat. Includes integral stainless strainer & adjustable flow control outlet. The thread of the vent is M6 and diameter of the vent hole is 1mm on all units.

| Model | Size | Media Pressure | Media Temperature |

|---|---|---|---|

| AVS-04 | 1/2" | 0.1 to 20 Bar | -10°C to 180°C |

| AVS-05 | 3/4" | 0.1 to 20 Bar | -10°C to 180°C |

| AVS-06 | 1" | 0.1 to 20 Bar | -10°C to 180°C |

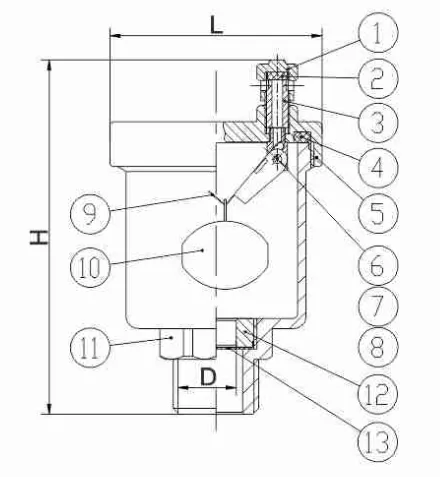

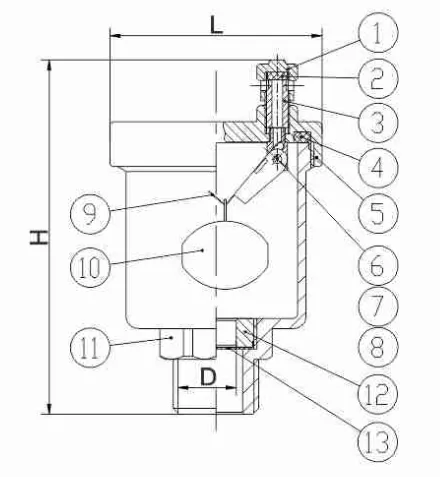

| Model | Size | L | H | D |

|---|---|---|---|---|

| AVS-04 | 1/2" | 52 | 88 | 10 |

| AVS-05 | 3/4" | 52 | 91 | 15 |

| AVS-06 | 1" | 52 | 93 | 22 |

All dimensions are in mm unless specified otherwise

| Item No. | Description | Material |

|---|---|---|

| 1 | Cap | SS304 |

| 2 | Gasket | FKM |

| 3 | Exhaust Column | SS304 |

| 4 | O-Ring | FKM |

| 5 | Bonnet | SS316 |

| 6 | Sealing Column | SS316 |

| 7 | Balancing Column | SS316 |

| Item No. | Description | Material |

|---|---|---|

| 8 | Gasket | FKM |

| 9 | Bouncing Slince | SS316 |

| 10 | Float | SS316 |

| 11 | Valve Body | SS316 |

| 12 | Lock Nut | SS304 |

| 13 | Strainer | SS304 |