Features:

Size 50mm to 300mm

Body Jotun Powder Coated Ductile Iron

Seat EPDM

Pressure Range 0 to 16 BAR

Operation Handwheel rising stem

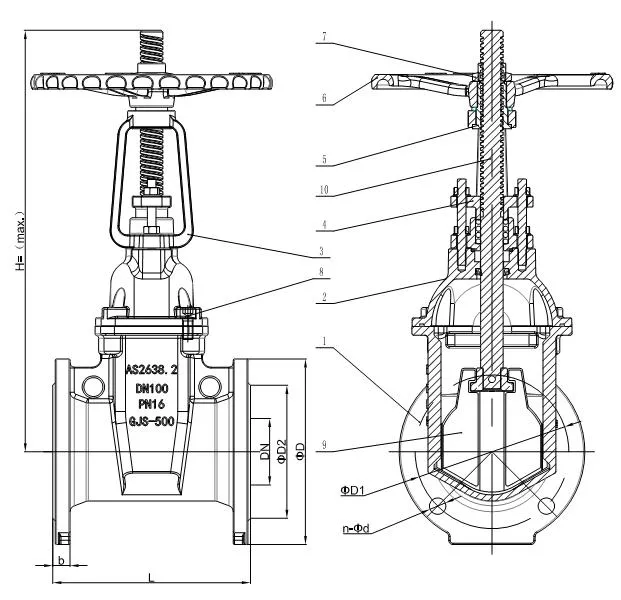

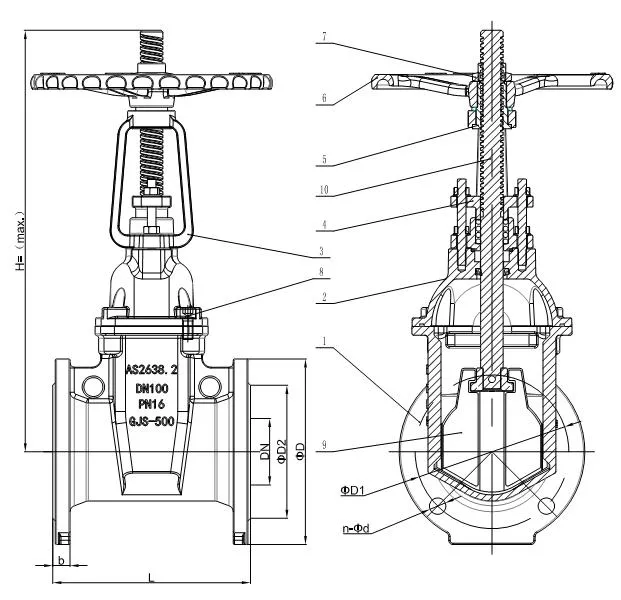

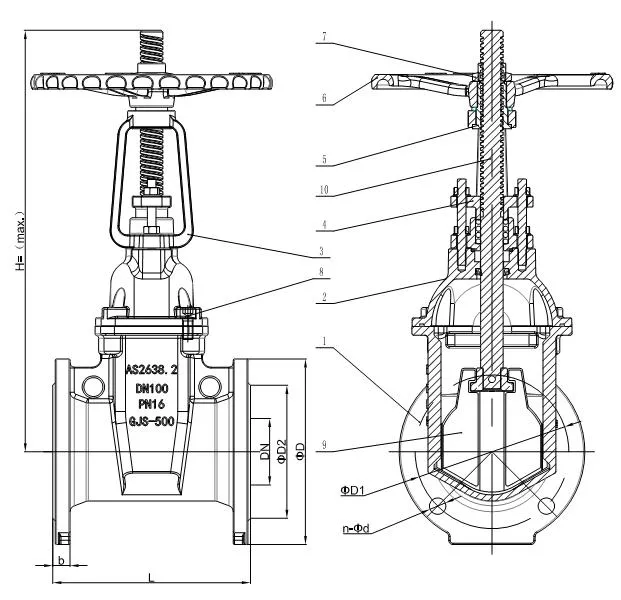

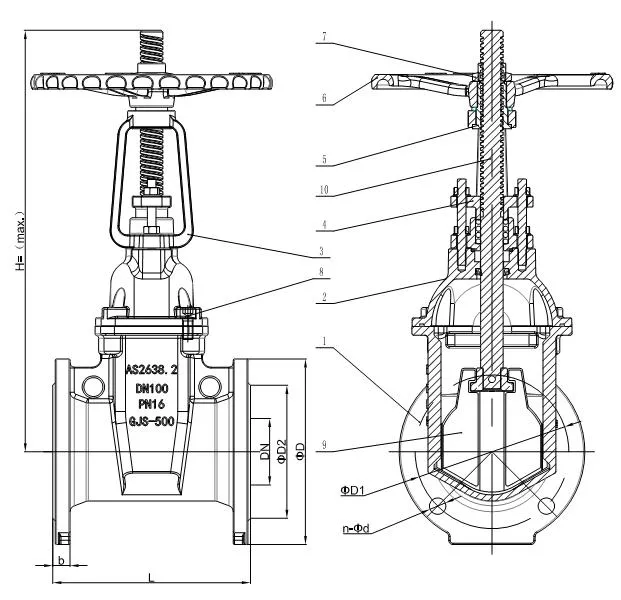

Resilient seated ductile iron gate valve also commonly known as a sluice valve. The gate valve is manually operated by a rising stem handwheel operation made in accordance with AS2638.2. AS4087 PN16 flanged (compatable with table D, fits Table E in some sizes, check dimensions table for compatability). Great for use in waste water, water treatment and fire industries. Outside stem and yoke, clockwise to close. All Bolt holes are silicone filled to avoid water pooling and corrosion. Gate valve features oversized SS431 shaft & stem, Bronze wedge nut, double shaft seals and twin lip seals to prevent ingress and egress of media and foreign material. This ensures the longest possible life of the valve as well as unrivalled performance.

All dimnsions in mm unless shown otherwise.

Size 50mm to 300mm

Body Jotun Powder Coated Ductile Iron

Seat EPDM

Pressure Range 0 to 16 BAR

Operation Handwheel rising stem

What is a Rising Stem Resilient Seated Gate Valve?

A rising stem resilient seated gate valve is a manual isolation valve designed to stop or allow the flow of fluids within a pipeline. It is constructed with a ductile iron body and bonnet, and features a rising stem handwheel which visibly indicates whether the valve is open or closed. The gate (wedge) is fully encapsulated in EPDM resilient material to provide a tight seal when closed. This valve is flanged to AS4087 PN16 standards, which is compatible with AS2129 Table D drilling and can fit Table E in some sizes.

How does a Rising Stem Resilient Seated Gate Valve work?

This gate valve works by raising and lowering a wedge-shaped gate inside the valve body. Turning the handwheel rotates the stem, which lifts the gate to allow flow or lowers it to block the flow. When the valve is fully open, the gate is completely withdrawn from the flow path, creating a full bore opening with minimal pressure loss. When closed, the resilient elastomer seat compresses against the valve body, providing a tight seal and preventing leakage. Because the sealing surface is resilient, these valves offer excellent shut-off performance even at lower pressures.

How long will my Rising Stem Resilient Seated Gate Valve last?

The service life of a resilient seated gate valve depends on the media, operating conditions, environment and how often the valve is cycled. These valves are commonly used in clean or mildly contaminated water systems and, when operated within their design limits, can provide many years of reliable service. The cast iron body provides mechanical strength, while the resilient seat protects the sealing surfaces from wear, making this valve well suited to civil, municipal and industrial water applications.

How do I install a Rising Stem Resilient Seated Gate Valve?

Before installation, ensure the pipeline is fully depressurised and drained. This valve has AS 4087 PN16 flanges, so it should be installed between matching flanges. Install a suitable flange gasket between the mating flange faces, insert the bolts and tighten them in a diagonal sequence to ensure even compression and correct sealing. Once installed, slowly bring the system up to operating pressure and inspect all flange connections for leaks. The valve should be installed in a location that allows easy access to the handwheel for operation.

What are typical uses of a Rising Stem Resilient Seated Gate Valve?

These resilient seated cast iron gate valves are widely used in applications where tight shut-off and reliable isolation are required. Typical applications includes potable and non-potable water supply systems, wastewater and sewage pipelines, irrigation and agricultural networks, stormwater systems and fire service and civil infrastructure applications.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 50mm to 300mm

Body Jotun Powder Coated Ductile Iron

Seat EPDM

Pressure Range 0 to 16 BAR

Operation Handwheel rising stem

Resilient seated ductile iron gate valve also commonly known as a sluice valve. The gate valve is manually operated by a rising stem handwheel operation made in accordance with AS2638.2. AS4087 PN16 flanged (compatable with table D, fits Table E in some sizes, check dimensions table for compatability). Great for use in waste water, water treatment and fire industries. Outside stem and yoke, clockwise to close. All Bolt holes are silicone filled to avoid water pooling and corrosion. Gate valve features oversized SS431 shaft & stem, Bronze wedge nut, double shaft seals and twin lip seals to prevent ingress and egress of media and foreign material. This ensures the longest possible life of the valve as well as unrivalled performance.

All dimnsions in mm unless shown otherwise.