Features:

Size 1/2" to 1" BSPT

Body Ductile Iron

Pressure Range 0 to 16 BAR

Temperature 0 to 220°C

| Application | Steam Condensate |

|---|---|

| Type | Inverted Bucket |

| Pressure | 0.1 to 16 Bar (varies for each model) |

| Temperature | 0°C to 220°C |

| Connection | BSPT (ISO 7.1) |

| Body | Ductile cast iron |

| Valve | Stainless Steel (Heat treated) |

| Valve Seat | Stainless Steel (Heat treated) |

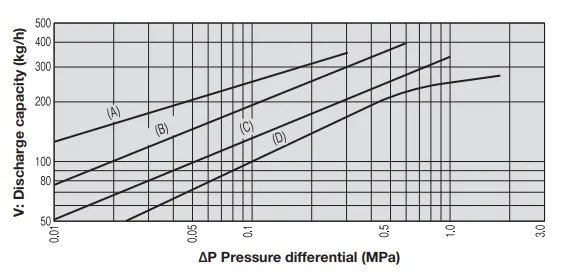

Discharge Capacity Chart

A) 0.1 to 3 Bar B) 2 to 6 Bar C) 3 to 10 Bar D) 6 to 16 Bar

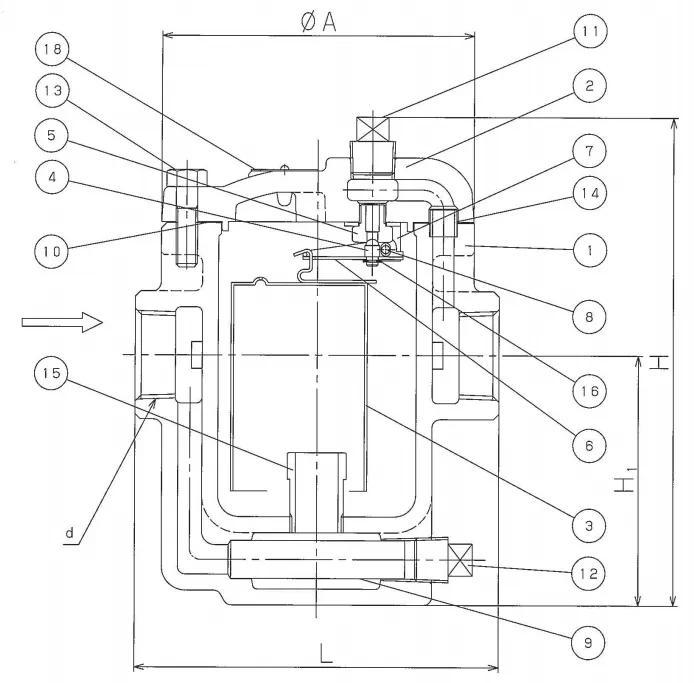

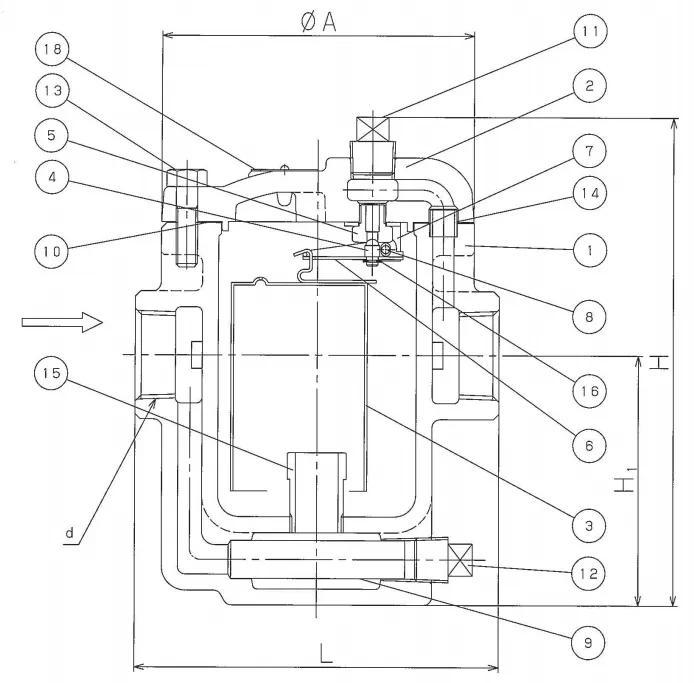

| DN | d | L | H | H1 | A | Kg |

|---|---|---|---|---|---|---|

| 15 | 1/2" Rc | 136 | 183 | 94 | 117 | 4.3 |

| 20 | 3/4" Rc | 136 | 183 | 94 | 117 | 4.3 |

| 25 | 1" Rc | 136 | 183 | 94 | 117 | 4.3 |

All dimensions in mm unless shown otherwise.

| Number | Part | Material | Grade | QTY |

|---|---|---|---|---|

| 1 | Body | Ductile Iron | FCD450 | 1 |

| 2 | Cover | Ductile Iron | FCD450 | 1 |

| 3 | Bucket | Stainless Steel | SUS304 | 1 |

| 4 | Valve | Stainless Steel | SUS420J2 | 1 |

| 5 | Valve Seat | Stainless Steel | SUS420J2 | 1 |

| 6 | Lever | Stainless Steel | SUS304 | 1 |

| 7 | Lever Holder | Stainless Steel | SUS304 | 1 |

| 8 | Spindle | Stainless Steel | SUS304 | 1 |

| 9 | Screen | Stainless Steel | SUS304 | 1 |

| 10 | Gasket | Graphite | Graphite | 1 |

| 11 | Plug | Stainless Steel | SUS304 | 1 |

| 12 | Plug | Malleable Cast Iron | FCMB310 | 1 |

| 13 | Bolts | Carbon Steel | SCM435 | 6 |

| 14 | Spacer | Carbon Steel | SPCC | 1 |

| 15 | Pipe | Stainless Steel | SUS304 | 1 |

| 16 | E Ring | Stainless Steel | SUS304 | 1 |

| 18 | Plate | Aluminium | A1050 | 1 |

Size 1/2" to 1" BSPT

Body Ductile Iron

Pressure Range 0 to 16 BAR

Temperature 0 to 220°C

What is an Inverted Bucket Steam Trap?

An Inverted Bucket steam trap is an automatic valve, designed to discharge condensate (water) without the loss of live steam. It functions by having the ability to differentiate between Steam, Air/Gas and Condensate via the difference in density between Steam as a gas & Condensate as a liquid. The intention is to discharge condensate and hold back steam.

How does an Inverted Bucket Steam Trap work?

An Inverted Bucket Steam Trap is a mechanical type steam trap and as the name suggests, it uses the buoyancy of an inverted bucket within the trap that is attached to a lever which opens and closes the trap valve in response to the bucket's movement. When steam or air flows into the underside of the inverted bucket with condensate surrounding it on the outside, the steam/air causes the bucket to become buoyant and rise upwards to close the valve. During normal operation, the discharge is generally intermittent depending on the load, at high loads the discharge can be almost continuous. They come in a variety of sizes, materials and capacities, with excellent tolerance to water hammer and can be used on superheated steam with the addition of a check valve on the inlet. There should always be a water seal around the lip of the bucket. If the trap loses this water seal, steam can be wasted through the outlet valve. This can happen where there is a sudden drop in the process steam pressure, causing some of the condensate in the trap to flash off into steam. The bucket will lose its buoyancy and sink, which can allow live steam to pass through the valve. It then needs to have enough condensate to enter the trap so the water seal can form again, and prevent steam loss. All mechanical traps usually require specific valve internals to match the steam system operating pressure/differential pressure. To understand how the Inverted Bucket creates movement, try this next time you are washing a plastic container or an ice cream container in the kitchen sink.Turn the container upside down (Invert It) and lower it into the water trying not to allow air to escape around the edges and you will feel the force of the buoyancy created by the trapped air. Controlling that trapped air/steam in a steam trap, by allowing it to escape, bleed off at a specific rate, allows the bucket to sink and open the valve. The steam trap will then cycle open and closed as required by the demand.

How long will my Inverted Bucket Steam Trap last?

This really depends upon the environment and the quality of your steam that the steam trap operates with. The installation of strainers is highly recommended to reduce the amount of dirt and other impurities from entering the steam trap internals. A correctly selected and sized Steam Trap with a good maintenance regime, should perform for many years. Obviously it should be installed in accordance with the manufacturer's recommendations and it is highly recommended that regular inspection of the steam trap is carried out at least once a year and if found to be faulty it should be cleaned and or repaired as required. This will give the valve the best opportunity to continually operate satisfactorily for many years. When a steam trap does fail it can lead to a loss of production and or a waste of energy through leaking steam, fuel bills will increase. Depending on the quality of your steam, It is a rule of thumb that 10/15% of steam traps will fail annually, so it is vitally important that regular checks for correct operation are carried out often.

How do I install an Inverted Bucket Steam Trap?

It is vitally important when selecting and sizing any type of steam trap, that certain criteria is met. Such as the operating pressure/temperature, the duty required, the application, back pressure etc. There is no such thing as a universal trap or one size fits all; each trap must be selected to suit the application. Steam Traps should always be installed in accordance with the manufacturers recommendations and in accordance with good steam fitting practice. In Particular always insure. Correct direction of flow. Correct orientation. Leave clear access for general maintenance and repairs.They can have various end connections such as flanged, threaded, socket weld etc so installation will need to take this into account. Always take into consideration the discharge of a steam trap and if it is going to the atmosphere, ensure it is discharging to a safe place, not to cause noise issues, damage to the environment or injury to animals and humans. Where practical, It is highly recommended that all condensate be returned to the boiler due to the high level of energy stored within the hot condensate. Steam condensate is also very clean/pure and will require less chemical treatment when returned to the boiler feed system, another cost saving reason to return to the boiler. With a water seal being integral to the correct operation of the Inverted Bucket steam trap avoiding the loss of the seal must be considered in the installation. To avoid steam leaks on the startup of a dry trap, during an installation, the trap can be pre primed with water, to ensure enough water is available to create the waterseal. If The steam trap is commissioned correctly priming is not always necessary. Also when an inverted bucket trap is used on an application where fluctuating pressures can be expected, this can cause some of the condensate in the trap to flash off, when pressure drops dramatically, such as with a quick acting on/off control valve. To avoid the loss of the seal due to flashing and any vacuum conditions, fit a check valve on the inlet line to the trap. This will maintain the flow in the correct direction, and reverse flow will be prevented as the check valve will close.

What are typical uses of a Inverted Bucket Steam Trap?

When saturated steam gives up its energy to any colder surface it condenses and condensate is formed. This condensate is usually a hindrance to heat transfer efficiency and a potential danger to the safe operation of any steam system in general. There are many applications for steam traps and many varied reasons why and where a steam trap may be required for any particular application. It is vitally important that those charged with selecting, sizing and installing a steam trap are also very familiar with steam and condensate system design and good steam fitting practice. The results of poor selection and installation can be catastrophic. Property has been damaged and humans have been injured and even killed as a result of poor condensate drainage from a steam system. Typical uses for Inverted Bucket steam traps are in applications where efficient heat transfer is required for production processes, draining Steam Separators, draining Shell & Tube and Plate and Frame heat exchangers, Steam Coil drainage, Tanks & Vats, Humidifiers, Air heater coils, Mash tanks, Steam Kettles, Calandrias etc etc. If you are unsure please contact us for more detailed sizing and selection support.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all steam traps that leave our warehouse are tested (full material and testing certificates are available) and inspected so there are rarely any issues.

Size 1/2" to 1" BSPT

Body Ductile Iron

Pressure Range 0 to 16 BAR

Temperature 0 to 220°C

| Application | Steam Condensate |

|---|---|

| Type | Inverted Bucket |

| Pressure | 0.1 to 16 Bar (varies for each model) |

| Temperature | 0°C to 220°C |

| Connection | BSPT (ISO 7.1) |

| Body | Ductile cast iron |

| Valve | Stainless Steel (Heat treated) |

| Valve Seat | Stainless Steel (Heat treated) |

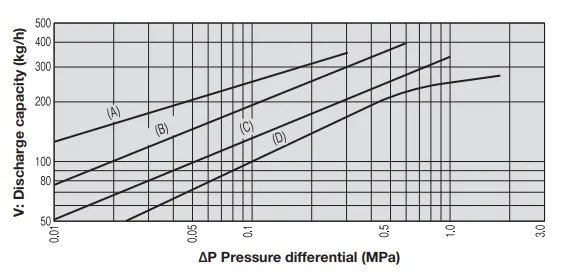

Discharge Capacity Chart

A) 0.1 to 3 Bar B) 2 to 6 Bar C) 3 to 10 Bar D) 6 to 16 Bar

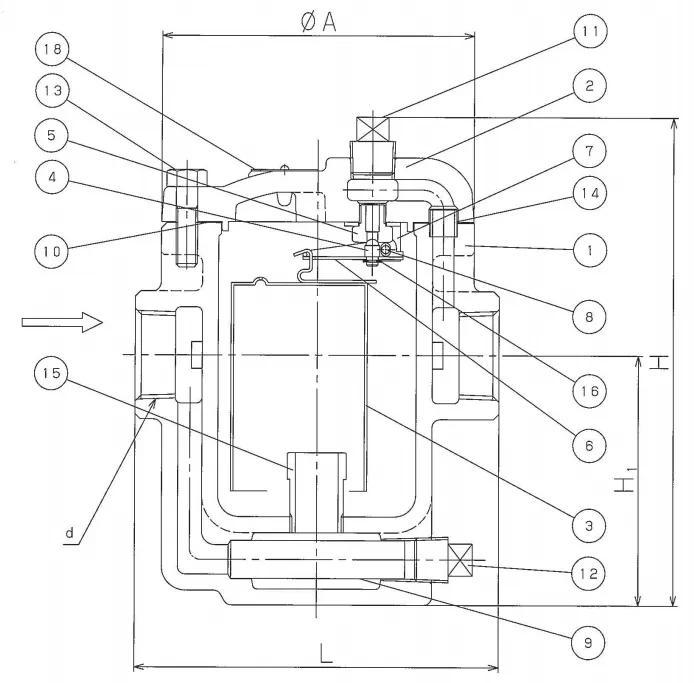

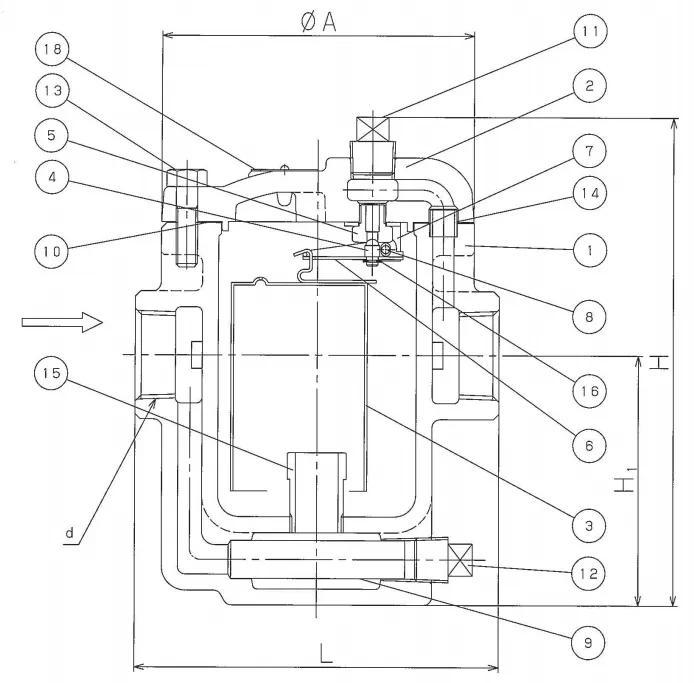

| DN | d | L | H | H1 | A | Kg |

|---|---|---|---|---|---|---|

| 15 | 1/2" Rc | 136 | 183 | 94 | 117 | 4.3 |

| 20 | 3/4" Rc | 136 | 183 | 94 | 117 | 4.3 |

| 25 | 1" Rc | 136 | 183 | 94 | 117 | 4.3 |

All dimensions in mm unless shown otherwise.

| Number | Part | Material | Grade | QTY |

|---|---|---|---|---|

| 1 | Body | Ductile Iron | FCD450 | 1 |

| 2 | Cover | Ductile Iron | FCD450 | 1 |

| 3 | Bucket | Stainless Steel | SUS304 | 1 |

| 4 | Valve | Stainless Steel | SUS420J2 | 1 |

| 5 | Valve Seat | Stainless Steel | SUS420J2 | 1 |

| 6 | Lever | Stainless Steel | SUS304 | 1 |

| 7 | Lever Holder | Stainless Steel | SUS304 | 1 |

| 8 | Spindle | Stainless Steel | SUS304 | 1 |

| 9 | Screen | Stainless Steel | SUS304 | 1 |

| 10 | Gasket | Graphite | Graphite | 1 |

| 11 | Plug | Stainless Steel | SUS304 | 1 |

| 12 | Plug | Malleable Cast Iron | FCMB310 | 1 |

| 13 | Bolts | Carbon Steel | SCM435 | 6 |

| 14 | Spacer | Carbon Steel | SPCC | 1 |

| 15 | Pipe | Stainless Steel | SUS304 | 1 |

| 16 | E Ring | Stainless Steel | SUS304 | 1 |

| 18 | Plate | Aluminium | A1050 | 1 |