Features:

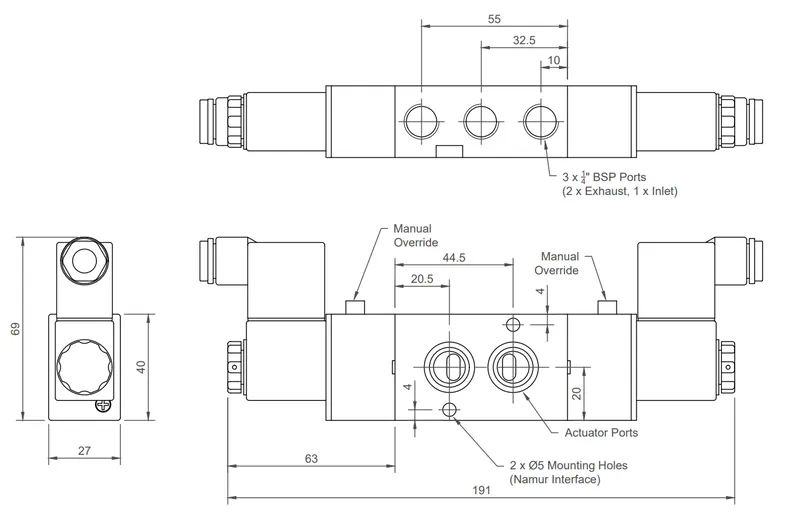

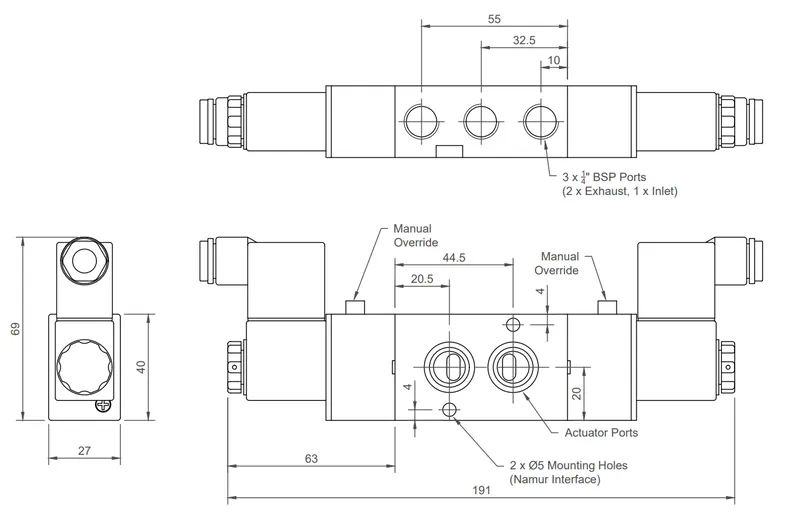

Size 1/4" BSP Only

Function 5 way 2 position double solenoid namur with manual override

Valve Operation Servo Assisted

Body Aluminium

Seat NBR

Pressure Range 1.5 to 8 BAR

Media Air

5 way 2 position solenoid valve (double solenoid, one each end) with namur interface making it suitable for direct mounting onto pneumatic actuators (both double acting and spring return). Standard features include manual override, led indicator plug (IP65), fully encapsulated low wattage coil. Includes mounting screws and gasket orings. Threads conform to ISO 7.1 Sealing Threads.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC

Size 1/4" BSP Only

Function 5 way 2 position double solenoid namur with manual override

Valve Operation Servo Assisted

Body Aluminium

Seat NBR

Pressure Range 1.5 to 8 BAR

Media Air

What is a Five Way Two Position Namur Double Solenoid Valve?

A Five Way Two Position Namur Double Solenoid Valve is a solenoid operated valve that has five ways and two positions with a coil at each end. The easiest way to explain this is that it has one supply port (pressure in), two advance ports (outlet ports that seal on the face of the pneumatic actuator) and two exhaust ports (ports that exhaust air from the actuator). It then has two positions or states which are opposite of each other; for instance in one state air will flow from one outlet port while air is exhausted back through the other port while it is reversed in its other state. The valve is changed position through a Solenoid Coil at each end which is commonly called bi-stable within the industry or by using the manual override buttons at each end.

How does a 5 way 2 position Double Solenoid Namur Valve work?

These valves are commonly referred to in the industry as a 5/2 Double Solenoid Namur Valves. This is because they have 5 ways and 2 positions, operated by a solenoid at each end and have a namur interface (directly mounts onto the face of the actuator). The solenoid coils have copper windings around it that when energised creates a magnetic field and lifts an armature in the valve. This allows the spool to move over within the valve (a minimum pressure differential is used to assist this) and move the valve to its other position. When the other coils is energised it will reverse the position. These can't really be referred to as Normally Closed or Normally Open like two way or three way valves as they are effectively always open, it just varies which of the two outlet ports it is coming out. The middle port on the bottom of the valve is the inlet or pressure supply port, from here it will go out one of the outlet ports which is directly interfaced with the actuator while the other outlet port will be taking the exhaust air from the other side of the actuator piston and directing that through the body of the valve to one of the exhaust ports on the bottom of the valve (next to the inlet pressure port). The valve is sealed to the face of the actuator by an o'ring seal around each of the outlet/advanced ports. When the valve is operated this sequence is just reversed. There is also a manual override button at each end of the valve. These buttons can be pressed to operate the valve without power.

How do I know that a 5/2 Namur Double Solenoid Valve is the right valve for me?

The first thing to check is if you want your 5/2 valve to mount directly to the actuator (which would be a namur) and what you want your pneumatic actuator to do. If this is just an open/close (full stroke) cycle and you want it to run off an electric signal at each end (we would call this set up an electric over air), then a 5/2 solenoid valve will be well suited. If you want an inching or creeping function where you can lock the actuator mid stroke then a 5/2 is not suited and you would need to move to a 5/3 solenoid valve which would allow this. The next thing to check is whether you want a single solenoid operation (most are just a single solenoid which you can see here) or a double solenoid namur which we call bi-stable as this model is. Once you have worked this out you can choose the correct voltage.

How long will my 5/2 Double Solenoid Namur Valve last?

Like any valve this depends upon the usage case, duty cycle and external environment of the valve. The pressure, temperature and characteristics of the media (eg. is it clean filtered air) will have a large bearing on how long your valve lasts. If your valve is cycling every second, 24 hours a day (ours are 100% duty rated which means they can do this as long as the heat can be dissipated) then its life will be shorter than one which is used once a day. Your valve also will take in a small amount of air from the atmosphere through the exhaust ports in the bottom of the valve as the spool moves over within the valve. We recommend using silencers or speed controllers to protect against ingress of foreign materials here. The electrical supply to your coil can also determine the valve's life as voltage spikes can short the coils (the same as any electrical equipment).

What are typical uses of a 5 way 2 position Namur Double Solenoid Valve ?

These 5/2 solenoid valves are really used to mount directly onto the face of pneumatic actuators to allow control of the actuator (open/close). This allows you to achieve an electric over air set up (where an electric signal controls a pneumatic actuator).

How do I install my 5/2 Double Solenoid Namur Valve?

The namur solenoid valve will be mounted directly over the pressure supply ports on your actuator (assuming your actuator has a namur interface which almost all do now days) so it is important to ensure this area is clean and dry. From here the 5/2 namur valve will be placed against the face of the actuator carefully ensuring that the two oring seals around the outlet ports of the 5/2 namur are still in place. Once this is verified the two socket head mounting bolts can be tightened up to hold the valve in place. The two exhaust ports on the bottom of the valve can be left open however we do recommend a silencer or exhaust speed controller is used to protect it from the surrounding environment. The DIN plug on the coil at each end can be connected to the power and ensure the entrance to the coil is facing down with a sufficient drip loop to avoid condensation running down the lead and into the plug.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days. You can rely on us to do everything to despatch your order the same day we receive it, this is what we do.

What warranty do I get?

We have been manufacturing Solenoid Valves for over 30 years so we have a lot of experience at making a great valve. All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all solenoid valves leave our warehouse tested (full material and testing certificates are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time barring any debris getting caught in the valve or power spikes causing the coil to fail.

Size 1/4" BSP Only

Function 5 way 2 position double solenoid namur with manual override

Valve Operation Servo Assisted

Body Aluminium

Seat NBR

Pressure Range 1.5 to 8 BAR

Media Air

5 way 2 position solenoid valve (double solenoid, one each end) with namur interface making it suitable for direct mounting onto pneumatic actuators (both double acting and spring return). Standard features include manual override, led indicator plug (IP65), fully encapsulated low wattage coil. Includes mounting screws and gasket orings. Threads conform to ISO 7.1 Sealing Threads.

*Voltages available; 12vDC, 24vDC, 24vAC, 110vAC, 240vAC, 415vAC