Features:

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure Range 0 to 20 BAR

Operation Handwheel rising stem

Rising stem Cast Steel ANSI 150 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve. Designed in accordance with API600 with face to face complying with ASME B16.10.

| Model | DN (mm) | Turns for full cycle | Pressure Range | Media Temp | Weight (kg) | Torque (Nm) |

|---|---|---|---|---|---|---|

| GVWR-50 | 50 | 7.5 | 0 to 20 BAR | -29°C to 425°C | 18 | 50 |

| GVWR-65 | 65 | 9 | 0 to 20 BAR | -29°C to 425°C | 25 | 63 |

| GVWR-80 | 80 | 12 | 0 to 20 BAR | -29°C to 425°C | 32 | 77 |

| GVWR-100 | 100 | 11 | 0 to 20 BAR | -29°C to 425°C | 46 | 92 |

| GVWR-125 | 125 | 14 | 0 to 20 BAR | -29°C to 425°C | 58 | 119 |

| GVWR-150 | 150 | 16 | 0 to 20 BAR | -29°C to 425°C | 79 | 139 |

| GVWR-200 | 200 | 22 | 0 to 20 BAR | -29°C to 425°C | 118 | 220 |

| GVWR-250 | 250 | 21.5 | 0 to 20 BAR | -29°C to 425°C | 180 | 270 |

| GVWR-300 | 300 | 26 | 0 to 20 BAR | -29°C to 425°C | 268 | 295 |

| GVWR-350 | 350 | 57.5 | 0 to 20 BAR | -29°C to 425°C | 360 | 420 |

| GVWR-400 | 400 | 66 | 0 to 20 BAR | -29°C to 425°C | 458 | 490 |

| GVWR-450 | 450 | 73.5 | 0 to 20 BAR | -29°C to 425°C | 579 | 510 |

| GVWR-500 | 500 | 81.5 | 0 to 20 BAR | -29°C to 425°C | 732 | 820 |

| GVWR-600 | 600 | 74 | 0 to 20 BAR | -29°C to 425°C | 1083 | 1100 |

.webp)

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | d (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | Handwheel Dia |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 178 ± 1.5 | 152 | 120.6 | 91.9 | 4-Ø19.0 | 17.5 | 388 | 324.5 | 200 |

| 65 | 190 ± 1.5 | 180 | 139.7 | 104.6 | 4-Ø19.0 | 20.7 | 434.5 | 357.5 | 200 |

| 80 | 203 ± 1.5 | 190 | 152.4 | 127.0 | 4-Ø19.0 | 22.4 | 509 | 414 | 240 |

| 100 | 229 ± 1.5 | 230 | 190.5 | 157.2 | 8-Ø19.0 | 22.4 | 578.5 | 465.5 | 280 |

| 125 | 254 ± 1.5 | 255 | 215.9 | 185.7 | 8-Ø22.2 | 22.4 | 666.5 | 522.5 | 280 |

| 150 | 267 ± 1.5 | 280 | 241.3 | 215.9 | 8-Ø22.2 | 23.9 | 773.5 | 604 | 320 |

| 200 | 292 ± 1.5 | 345 | 298.4 | 269.7 | 8-Ø22.2 | 27.0 | 959 | 739 | 360 |

| 250 | 330 ± 2 | 405 | 362 | 323.8 | 12-Ø25.4 | 28.6 | 1165 | 890 | 400 |

| 300 | 356 ± 3 | 485 | 431.8 | 381 | 12-Ø25.4 | 30.2 | 1367 | 1039 | 450 |

| 350 | 381 ± 3 | 535 | 476.3 | 412.8 | 12-Ø28.5 | 33.4 | 1546 | 1181 | 560 |

| 400 | 406 ± 3 | 595 | 539.8 | 469.9 | 16-Ø28.5 | 35 | 1744 | 1326 | 560 |

| 450 | 432 ± 3 | 635 | 577.9 | 533.4 | 16-Ø31.8 | 38.1 | 1930 | 1440 | 640 |

| 500 | 457 ± 3 | 700 | 635 | 584.2 | 20-Ø31.8 | 41.3 | 2135 | 1597 | 640 |

| 600 | 508 ± 3 | 815 | 749.3 | 692.2 | 20-Ø35 | 46.1 | 2531 | 1906.5 | 720 |

All dimensions in mm unless shown otherwise.

.webp)

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-24") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 410 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure Range 0 to 20 BAR

Operation Handwheel rising stem

What is a ANSI 150 Flanged Cast Steel Gate Valve?

An ANSI 150 flanged cast steel gate valve is a manual isolation valve designed to start or stop the flow of liquids and gases in a high-pressure industrial pipeline. It has ANSI 150 flanged ends which allow it to be bolted directly between matching ANSI 150 flanges, making it suitable for systems built to ASME B16.5 standards.The valve body is manufactured from carbon steel (ASTM A216 WCB) with a metal seat design, providing strength and durability for heavy-duty applications such as petrochemical, steam, oil and high temperature systems.

How does a ANSI 150 Flanged Cast Steel Gate Valve work?

A gate valve operates by moving a disc-shaped gate perpendicular to the flow path. Turning the hand wheel rotates the stem which either lifts the gate out of the way to allow flow or lowers it down to block the flow. When fully open, the gate retracts into the body, creating a full bore straight-through flow path with minimal resistance or pressure drop. These valves are designed for on/off isolation and are not suitable for throttling or flow regulation, as partially opening the gate can cause vibration, turbulence and accelerated wear on the seating surfaces.

How long will my ANSI 150 Flanged Cast Steel Gate Valve last?

The service life depends on the operating environment, media, temperature and how often the valve is cycled. Cast steel gate valves are engineered for robust performance in demanding industrial applications. When used within their design limits, such as steam, oil, gas and other industrial fluids, these valves can provide many years of reliable service. Their metal-to-metal seats and heavy-duty construction enhance longevity under repeated use.

How do I install a ANSI 150 Flanged Cast Steel Gate Valve?

Before installation, ensure the system is fully depressurised and drained. This valve has ANSI 150 flanged ends, so it should be installed between two matching ANSI 150 flanges in your pipeline. Place a suitable flange gasket between the flange faces and then insert the flange bolts. Tighten the bolts in a diagonal pattern to ensure even compression and correct sealing. Once installed, slowly bring the system up to the working pressure and check for any leaks around the flange connections. Correct alignment of the flanges and gaskets is essential to achieve a positive seal and prevent stress on the valve body and pipeline.

What are typical uses of a ANSI 150 Flanged Cast Steel Gate Valve?

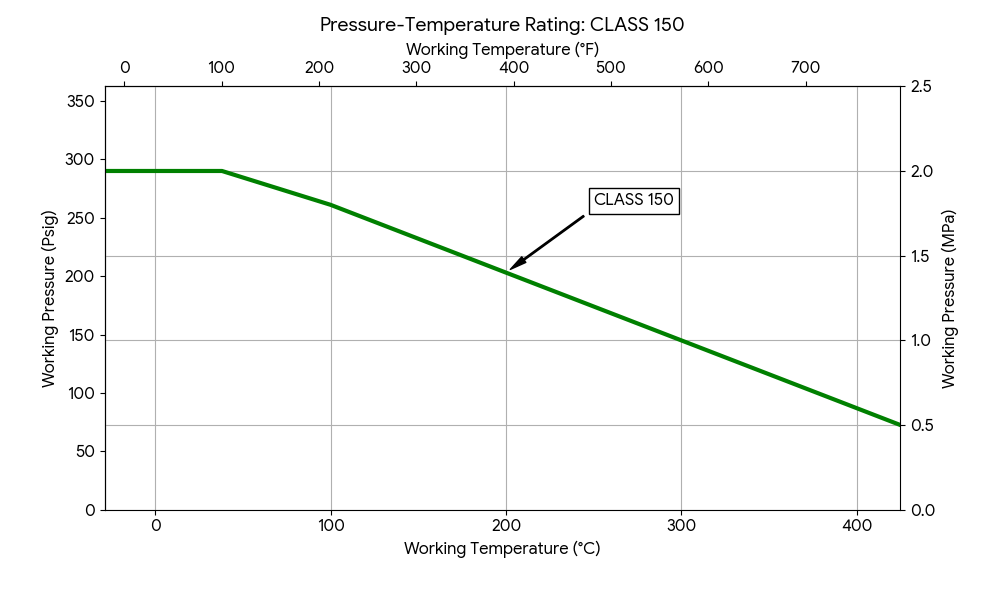

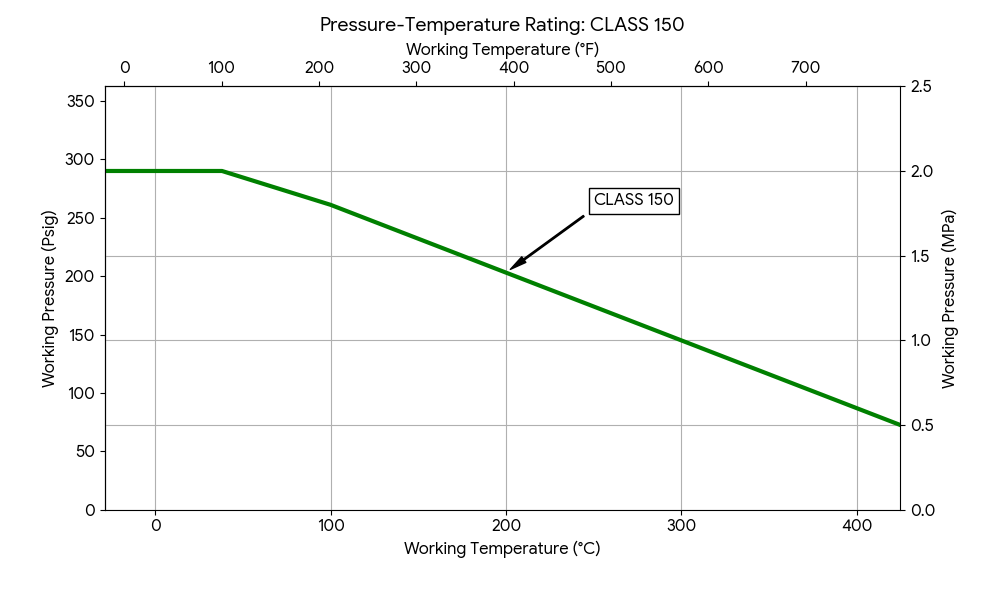

These cast steel gate valves are widely used in industrial and high-pressure systems where reliable isolation is required. Common applications includes steam and thermal fluid systems, petrochemical and refinery pipelines, oil and gas distribution and power generation and utility plants. The ANSI 150 rating makes this valve suitable for pressure up to approximately 20 bar at ambient temperatures, and temperature performance from about –29 °C to +425 °C.

How long will my product take to get to me?

This depends upon where you are based and the freight method chosen. If the express freight option is selected it is usually next day delivery to metropolitan areas in Australia for under 5kg. If free freight has been selected it will go by road freight which can be anywhere from 1 to 10 days depending upon your location. It usually averages 3 days.

What warranty do I get?

All of our products come standard with a 12 month warranty. The good news is we have very strict quality controls and all valves leave our warehouse tested (full material and testing certificates to API598 are available) and inspected so there are rarely any issues. Also once your valve is in and operating it will most likely continue to do so for a very long time.

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure Range 0 to 20 BAR

Operation Handwheel rising stem

Rising stem Cast Steel ANSI 150 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve. Designed in accordance with API600 with face to face complying with ASME B16.10.

| Model | DN (mm) | Turns for full cycle | Pressure Range | Media Temp | Weight (kg) | Torque (Nm) |

|---|---|---|---|---|---|---|

| GVWR-50 | 50 | 7.5 | 0 to 20 BAR | -29°C to 425°C | 18 | 50 |

| GVWR-65 | 65 | 9 | 0 to 20 BAR | -29°C to 425°C | 25 | 63 |

| GVWR-80 | 80 | 12 | 0 to 20 BAR | -29°C to 425°C | 32 | 77 |

| GVWR-100 | 100 | 11 | 0 to 20 BAR | -29°C to 425°C | 46 | 92 |

| GVWR-125 | 125 | 14 | 0 to 20 BAR | -29°C to 425°C | 58 | 119 |

| GVWR-150 | 150 | 16 | 0 to 20 BAR | -29°C to 425°C | 79 | 139 |

| GVWR-200 | 200 | 22 | 0 to 20 BAR | -29°C to 425°C | 118 | 220 |

| GVWR-250 | 250 | 21.5 | 0 to 20 BAR | -29°C to 425°C | 180 | 270 |

| GVWR-300 | 300 | 26 | 0 to 20 BAR | -29°C to 425°C | 268 | 295 |

| GVWR-350 | 350 | 57.5 | 0 to 20 BAR | -29°C to 425°C | 360 | 420 |

| GVWR-400 | 400 | 66 | 0 to 20 BAR | -29°C to 425°C | 458 | 490 |

| GVWR-450 | 450 | 73.5 | 0 to 20 BAR | -29°C to 425°C | 579 | 510 |

| GVWR-500 | 500 | 81.5 | 0 to 20 BAR | -29°C to 425°C | 732 | 820 |

| GVWR-600 | 600 | 74 | 0 to 20 BAR | -29°C to 425°C | 1083 | 1100 |

.webp)

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | d (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | Handwheel Dia |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 178 ± 1.5 | 152 | 120.6 | 91.9 | 4-Ø19.0 | 17.5 | 388 | 324.5 | 200 |

| 65 | 190 ± 1.5 | 180 | 139.7 | 104.6 | 4-Ø19.0 | 20.7 | 434.5 | 357.5 | 200 |

| 80 | 203 ± 1.5 | 190 | 152.4 | 127.0 | 4-Ø19.0 | 22.4 | 509 | 414 | 240 |

| 100 | 229 ± 1.5 | 230 | 190.5 | 157.2 | 8-Ø19.0 | 22.4 | 578.5 | 465.5 | 280 |

| 125 | 254 ± 1.5 | 255 | 215.9 | 185.7 | 8-Ø22.2 | 22.4 | 666.5 | 522.5 | 280 |

| 150 | 267 ± 1.5 | 280 | 241.3 | 215.9 | 8-Ø22.2 | 23.9 | 773.5 | 604 | 320 |

| 200 | 292 ± 1.5 | 345 | 298.4 | 269.7 | 8-Ø22.2 | 27.0 | 959 | 739 | 360 |

| 250 | 330 ± 2 | 405 | 362 | 323.8 | 12-Ø25.4 | 28.6 | 1165 | 890 | 400 |

| 300 | 356 ± 3 | 485 | 431.8 | 381 | 12-Ø25.4 | 30.2 | 1367 | 1039 | 450 |

| 350 | 381 ± 3 | 535 | 476.3 | 412.8 | 12-Ø28.5 | 33.4 | 1546 | 1181 | 560 |

| 400 | 406 ± 3 | 595 | 539.8 | 469.9 | 16-Ø28.5 | 35 | 1744 | 1326 | 560 |

| 450 | 432 ± 3 | 635 | 577.9 | 533.4 | 16-Ø31.8 | 38.1 | 1930 | 1440 | 640 |

| 500 | 457 ± 3 | 700 | 635 | 584.2 | 20-Ø31.8 | 41.3 | 2135 | 1597 | 640 |

| 600 | 508 ± 3 | 815 | 749.3 | 692.2 | 20-Ø35 | 46.1 | 2531 | 1906.5 | 720 |

All dimensions in mm unless shown otherwise.

.webp)

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-24") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 410 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |