Features:

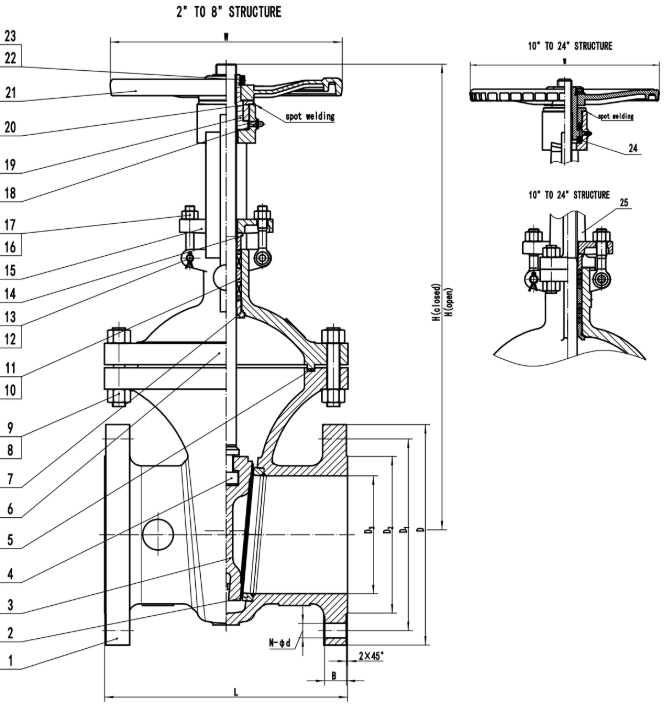

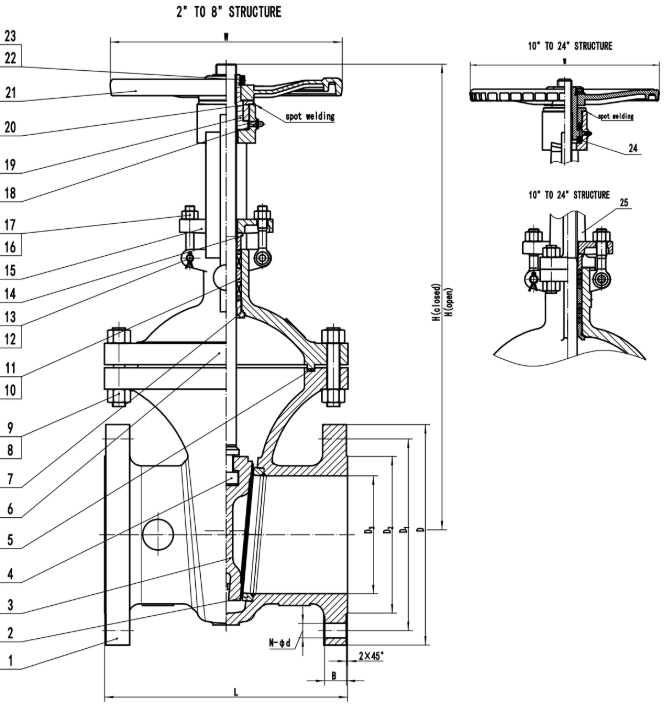

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

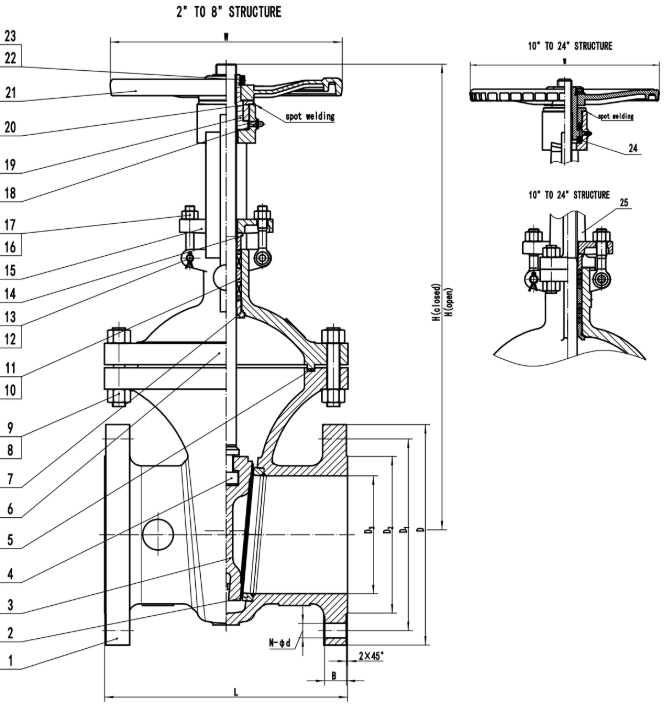

Rising stem Cast Steel (WCB) ANSI 300 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve.

| Model | DN | Pressure Range (at Ambient Temp) | Media Temp | Weight (kg) |

|---|---|---|---|---|

| GVWR3-050 | 50 | 0 to 50 Bar | 315°C at 38 Bar | 23 |

| GVWR3-065 | 65 | 0 to 50 Bar | 315°C at 38 Bar | 35 |

| GVWR3-080 | 80 | 0 to 50 Bar | 315°C at 38 Bar | 50 |

| GVWR3-100 | 100 | 0 to 50 Bar | 315°C at 38 Bar | 71 |

| GVWR3-150 | 150 | 0 to 50 Bar | 315°C at 38 Bar | 144 |

| GVWR3-200 | 200 | 0 to 50 Bar | 315°C at 38 Bar | 209 |

| GVWR3-250 | 250 | 0 to 50 Bar | 315°C at 38 Bar | 322 |

| GVWR3-300 | 300 | 0 to 50 Bar | 315°C at 38 Bar | 482 |

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | N-ød (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | W (Handwheel Dia.) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 216 ± 1.5 | 165 | 127 | 92.1 | 8-Ø19 | 20.7 | 408 | 340 | 200 |

| 65 | 241 ± 1.5 | 190 | 149.2 | 104.8 | 8-Ø22.5 | 23.9 | 460 | 386 | 200 |

| 80 | 282 ± 1.5 | 210 | 168.3 | 127 | 8-Ø22.5 | 27 | 530 | 435 | 240 |

| 100 | 305 ± 1.5 | 255 | 200 | 157.2 | 8-Ø22.5 | 30.2 | 619 | 502 | 280 |

| 125 | 381 ± 1.5 | 280 | 235 | 186 | 8-Ø22.5 | 33.4 | 748 | 605 | 320 |

| 150 | 403 ± 1.5 | 320 | 269.9 | 215.9 | 12-Ø22.5 | 35 | 826 | 660 | 360 |

| 200 | 419 ± 1.5 | 380 | 330.2 | 269.9 | 12-Ø25.5 | 39.7 | 1038 | 807 | 400 |

| 250 | 457 ± 1.5 | 445 | 387.4 | 323.8 | 16-Ø28.5 | 46.1 | 1247 | 972 | 450 |

| 300 | 502 ± 2 | 520 | 450.8 | 381 | 16-Ø32 | 49.3 | 1436 | 1107 | 560 |

| 350 | 762 ± 3 | 585 | 514.4 | 412.8 | 20-Ø32 | 52.4 | 1595 | 1230 | 640 |

| 400 | 838 ± 3 | 650 | 571.5 | 469.9 | 20-Ø35 | 55.6 | 1797 | 1383 | 720 |

| 450 | 914 ± 3 | 710 | 628.6 | 533.4 | 24-Ø35 | 58.8 | 1994 | 1530 | 800 |

| 500 | 991 ± 3 | 775 | 685.8 | 584.2 | 24-Ø35 | 62 | 2204 | 1687 | 950 |

| 600 | 1143 ± 3 | 915 | 812.8 | 692.2 | 24-Ø41.5 | 67.3 | 2605 | 1984 | 1100 |

All dimensions in mm unless shown otherwise.

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-8") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 420 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

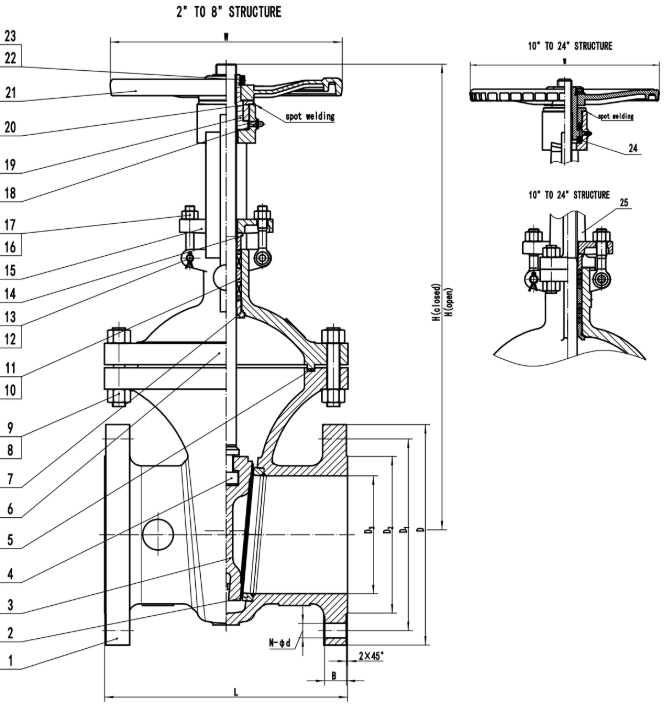

Rising stem Cast Steel (WCB) ANSI 300 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve.

| Model | DN | Pressure Range (at Ambient Temp) | Media Temp | Weight (kg) |

|---|---|---|---|---|

| GVWR3-050 | 50 | 0 to 50 Bar | 315°C at 38 Bar | 23 |

| GVWR3-065 | 65 | 0 to 50 Bar | 315°C at 38 Bar | 35 |

| GVWR3-080 | 80 | 0 to 50 Bar | 315°C at 38 Bar | 50 |

| GVWR3-100 | 100 | 0 to 50 Bar | 315°C at 38 Bar | 71 |

| GVWR3-150 | 150 | 0 to 50 Bar | 315°C at 38 Bar | 144 |

| GVWR3-200 | 200 | 0 to 50 Bar | 315°C at 38 Bar | 209 |

| GVWR3-250 | 250 | 0 to 50 Bar | 315°C at 38 Bar | 322 |

| GVWR3-300 | 300 | 0 to 50 Bar | 315°C at 38 Bar | 482 |

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | N-ød (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | W (Handwheel Dia.) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 216 ± 1.5 | 165 | 127 | 92.1 | 8-Ø19 | 20.7 | 408 | 340 | 200 |

| 65 | 241 ± 1.5 | 190 | 149.2 | 104.8 | 8-Ø22.5 | 23.9 | 460 | 386 | 200 |

| 80 | 282 ± 1.5 | 210 | 168.3 | 127 | 8-Ø22.5 | 27 | 530 | 435 | 240 |

| 100 | 305 ± 1.5 | 255 | 200 | 157.2 | 8-Ø22.5 | 30.2 | 619 | 502 | 280 |

| 125 | 381 ± 1.5 | 280 | 235 | 186 | 8-Ø22.5 | 33.4 | 748 | 605 | 320 |

| 150 | 403 ± 1.5 | 320 | 269.9 | 215.9 | 12-Ø22.5 | 35 | 826 | 660 | 360 |

| 200 | 419 ± 1.5 | 380 | 330.2 | 269.9 | 12-Ø25.5 | 39.7 | 1038 | 807 | 400 |

| 250 | 457 ± 1.5 | 445 | 387.4 | 323.8 | 16-Ø28.5 | 46.1 | 1247 | 972 | 450 |

| 300 | 502 ± 2 | 520 | 450.8 | 381 | 16-Ø32 | 49.3 | 1436 | 1107 | 560 |

| 350 | 762 ± 3 | 585 | 514.4 | 412.8 | 20-Ø32 | 52.4 | 1595 | 1230 | 640 |

| 400 | 838 ± 3 | 650 | 571.5 | 469.9 | 20-Ø35 | 55.6 | 1797 | 1383 | 720 |

| 450 | 914 ± 3 | 710 | 628.6 | 533.4 | 24-Ø35 | 58.8 | 1994 | 1530 | 800 |

| 500 | 991 ± 3 | 775 | 685.8 | 584.2 | 24-Ø35 | 62 | 2204 | 1687 | 950 |

| 600 | 1143 ± 3 | 915 | 812.8 | 692.2 | 24-Ø41.5 | 67.3 | 2605 | 1984 | 1100 |

All dimensions in mm unless shown otherwise.

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-8") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 420 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |

Size 50mm to 300mm

Body Carbon Steel (WCB)

Seat Metal

Pressure 50 Bar @ ambient

Operation Handwheel rising stem

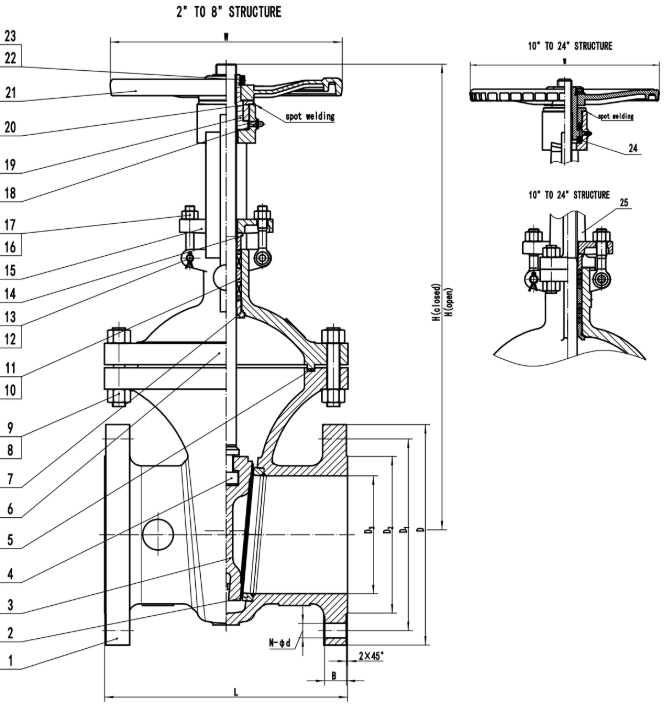

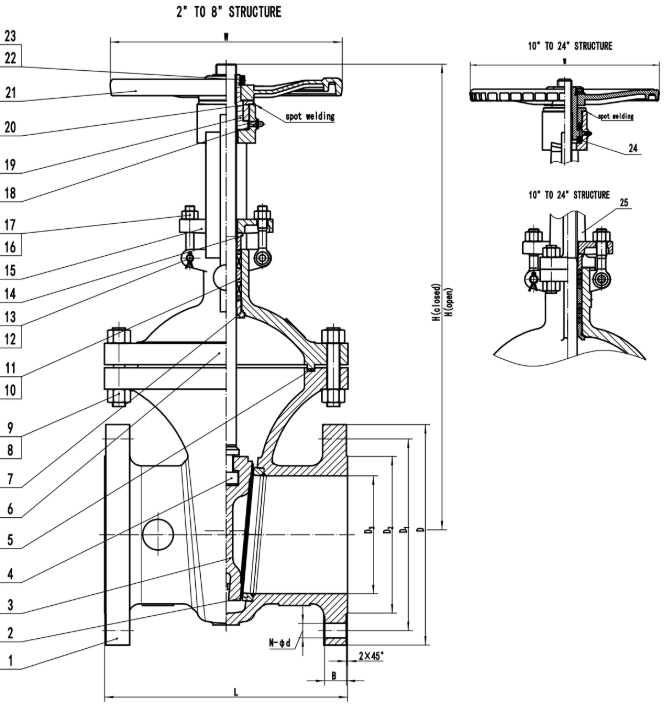

Rising stem Cast Steel (WCB) ANSI 300 Flanged Gate Valve. Used extensively in petrochemical and high temperature applications as an isolation valve.

| Model | DN | Pressure Range (at Ambient Temp) | Media Temp | Weight (kg) |

|---|---|---|---|---|

| GVWR3-050 | 50 | 0 to 50 Bar | 315°C at 38 Bar | 23 |

| GVWR3-065 | 65 | 0 to 50 Bar | 315°C at 38 Bar | 35 |

| GVWR3-080 | 80 | 0 to 50 Bar | 315°C at 38 Bar | 50 |

| GVWR3-100 | 100 | 0 to 50 Bar | 315°C at 38 Bar | 71 |

| GVWR3-150 | 150 | 0 to 50 Bar | 315°C at 38 Bar | 144 |

| GVWR3-200 | 200 | 0 to 50 Bar | 315°C at 38 Bar | 209 |

| GVWR3-250 | 250 | 0 to 50 Bar | 315°C at 38 Bar | 322 |

| GVWR3-300 | 300 | 0 to 50 Bar | 315°C at 38 Bar | 482 |

| Size | L | D (Flange OD) | D1 (PCD) | D2 (Raised Face OD) | N-ød (Holes) | B (Flange Thickness) | H (Open) | H (Closed) | W (Handwheel Dia.) |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 216 ± 1.5 | 165 | 127 | 92.1 | 8-Ø19 | 20.7 | 408 | 340 | 200 |

| 65 | 241 ± 1.5 | 190 | 149.2 | 104.8 | 8-Ø22.5 | 23.9 | 460 | 386 | 200 |

| 80 | 282 ± 1.5 | 210 | 168.3 | 127 | 8-Ø22.5 | 27 | 530 | 435 | 240 |

| 100 | 305 ± 1.5 | 255 | 200 | 157.2 | 8-Ø22.5 | 30.2 | 619 | 502 | 280 |

| 125 | 381 ± 1.5 | 280 | 235 | 186 | 8-Ø22.5 | 33.4 | 748 | 605 | 320 |

| 150 | 403 ± 1.5 | 320 | 269.9 | 215.9 | 12-Ø22.5 | 35 | 826 | 660 | 360 |

| 200 | 419 ± 1.5 | 380 | 330.2 | 269.9 | 12-Ø25.5 | 39.7 | 1038 | 807 | 400 |

| 250 | 457 ± 1.5 | 445 | 387.4 | 323.8 | 16-Ø28.5 | 46.1 | 1247 | 972 | 450 |

| 300 | 502 ± 2 | 520 | 450.8 | 381 | 16-Ø32 | 49.3 | 1436 | 1107 | 560 |

| 350 | 762 ± 3 | 585 | 514.4 | 412.8 | 20-Ø32 | 52.4 | 1595 | 1230 | 640 |

| 400 | 838 ± 3 | 650 | 571.5 | 469.9 | 20-Ø35 | 55.6 | 1797 | 1383 | 720 |

| 450 | 914 ± 3 | 710 | 628.6 | 533.4 | 24-Ø35 | 58.8 | 1994 | 1530 | 800 |

| 500 | 991 ± 3 | 775 | 685.8 | 584.2 | 24-Ø35 | 62 | 2204 | 1687 | 950 |

| 600 | 1143 ± 3 | 915 | 812.8 | 692.2 | 24-Ø41.5 | 67.3 | 2605 | 1984 | 1100 |

All dimensions in mm unless shown otherwise.

| No. | Part | Material |

|---|---|---|

| 1 | BODY | ASTM A216 WCB |

| 2 | SEAT | ASTM A105+13CR |

| 3 | WEDGE (2"-4") | ASTM A217 CA15+13CR |

| WEDGE (5"-8") | ASTM A216 WCB+13CR | |

| 4 | STEM | ASTM A182 F6a Cl.2 |

| 5 | GASKET | SS304+Graphite |

| 6 | BONNET | ASTM A216 WCB |

| 7 | BACK SEAT | ASTM A276 420 |

| 8 | BOLT | ASTM A193 B7 |

| 9 | NUT | ASTM A194 2H |

| 10 | SPACER RING | ASTM A276 420 |

| 11 | PACKING | Braided Graphite & Die formed Graphite Ring |

| 12 | PIN | AISI 1035 |

| 13 | COTTER | Q235 |

| 14 | GLAND | ASTM A276 420 |

| 15 | GLAND FLANGE | ASTM A216 WCB |

| 16 | EYE BOLT | ASTM A193 B7 |

| 17 | NUT | ASTM A194 2H |

| 18 | GREASE FITTING | C.S |

| 19 | STEM NUT | ASTM A439 D-2 |

| 20 | BEARING GLAND | AISI 1020 |

| 21 | HANDWHEEL | ASTM A536 65-45-12 |

| 22 | LOCK NUT | AISI 1020 |

| 23 | BOLT | AISI 1045 |

| 24 | BEARING | GCr15 |

| 25 | BRACKET | ASTM A216 WCB |